What is Global Aerospace-grade PEEK Market?

The Global Aerospace-grade PEEK Market refers to the international market for Polyether Ether Ketone (PEEK), a high-performance engineering thermoplastic used extensively in the aerospace industry. PEEK is known for its exceptional mechanical properties, including high strength, lightweight, and resistance to extreme temperatures and chemicals, making it ideal for aerospace applications. This market encompasses the production, distribution, and application of PEEK materials specifically designed to meet the stringent requirements of aerospace components. The demand for aerospace-grade PEEK is driven by the need for materials that can withstand harsh environments while contributing to fuel efficiency and reducing overall aircraft weight. As the aerospace industry continues to evolve with advancements in technology and increasing emphasis on sustainability, the role of PEEK in manufacturing aircraft components is becoming more significant. The market is characterized by continuous research and development efforts to enhance the properties of PEEK and expand its applications in both military and civil aviation sectors. The global aerospace-grade PEEK market is a dynamic and growing sector, reflecting the broader trends in the aerospace industry towards innovation and efficiency.

Unfilled PEEK Resin, Glass Fiber Reinforced PEEK, Carbon Fiber Reinforced PEEK in the Global Aerospace-grade PEEK Market:

Unfilled PEEK resin, Glass Fiber Reinforced PEEK, and Carbon Fiber Reinforced PEEK are three primary forms of PEEK used in the aerospace industry, each offering unique properties and advantages. Unfilled PEEK resin is the purest form of PEEK, without any additives or fillers. It is known for its excellent chemical resistance, high-temperature stability, and mechanical strength. This makes it suitable for applications where purity and performance are critical, such as in the production of seals, bearings, and other components that require high precision and reliability. Unfilled PEEK is often used in environments where exposure to harsh chemicals and extreme temperatures is common, ensuring long-lasting performance and minimal maintenance. Glass Fiber Reinforced PEEK, on the other hand, incorporates glass fibers into the PEEK matrix, enhancing its mechanical properties. The addition of glass fibers significantly increases the material's strength and stiffness, making it ideal for structural applications in the aerospace industry. This form of PEEK is often used in the manufacturing of aircraft interior components, brackets, and other parts that require enhanced durability and load-bearing capacity. The glass fibers also improve the material's dimensional stability, ensuring that components maintain their shape and performance over time, even under varying environmental conditions. Carbon Fiber Reinforced PEEK is another variant that combines PEEK with carbon fibers, resulting in a material with exceptional strength-to-weight ratio. This makes it particularly valuable in aerospace applications where weight reduction is a critical factor. Carbon Fiber Reinforced PEEK is used in the production of lightweight structural components, such as wing parts, fuselage sections, and other critical components that contribute to the overall efficiency and performance of the aircraft. The carbon fibers provide superior strength and rigidity, while the PEEK matrix offers excellent resistance to wear, chemicals, and high temperatures, ensuring that components can withstand the demanding conditions of aerospace environments. Each of these forms of PEEK offers distinct advantages, allowing manufacturers to select the most appropriate material for specific applications within the aerospace industry. The choice between Unfilled PEEK resin, Glass Fiber Reinforced PEEK, and Carbon Fiber Reinforced PEEK depends on the specific requirements of the application, including factors such as mechanical performance, weight considerations, and environmental conditions. As the aerospace industry continues to advance, the development and application of these PEEK materials are expected to grow, driven by the need for high-performance, lightweight, and durable materials that can meet the evolving demands of modern aircraft design and manufacturing.

Military Aviation, Civil Aviation in the Global Aerospace-grade PEEK Market:

The usage of Global Aerospace-grade PEEK Market materials in military aviation is driven by the need for high-performance components that can withstand the rigorous demands of military operations. In military aviation, PEEK is used in a variety of applications, including the production of lightweight structural components, electrical connectors, and insulation materials. The material's exceptional strength-to-weight ratio and resistance to extreme temperatures and chemicals make it ideal for use in military aircraft, where performance and reliability are critical. PEEK components are often used in the production of advanced fighter jets, helicopters, and unmanned aerial vehicles (UAVs), where they contribute to improved fuel efficiency, reduced maintenance requirements, and enhanced overall performance. In civil aviation, the use of aerospace-grade PEEK materials is similarly driven by the need for lightweight, durable, and high-performance components. PEEK is used in the production of a wide range of aircraft components, including interior fittings, structural parts, and engine components. The material's ability to withstand high temperatures and harsh environmental conditions makes it ideal for use in commercial aircraft, where safety and reliability are paramount. PEEK components are often used in the production of passenger aircraft, cargo planes, and other commercial aviation applications, where they contribute to improved fuel efficiency, reduced emissions, and enhanced passenger comfort. The use of PEEK in both military and civil aviation is also driven by the increasing emphasis on sustainability and environmental responsibility within the aerospace industry. As aircraft manufacturers seek to reduce the environmental impact of their products, the use of lightweight materials like PEEK is becoming increasingly important. By reducing the overall weight of aircraft, PEEK components help to improve fuel efficiency and reduce emissions, contributing to the industry's broader sustainability goals. Overall, the usage of Global Aerospace-grade PEEK Market materials in military and civil aviation reflects the broader trends within the aerospace industry towards innovation, efficiency, and sustainability. As the industry continues to evolve, the demand for high-performance materials like PEEK is expected to grow, driven by the need for components that can meet the rigorous demands of modern aircraft design and manufacturing. The versatility and performance of PEEK make it an ideal choice for a wide range of applications within the aerospace industry, ensuring its continued relevance and importance in the years to come.

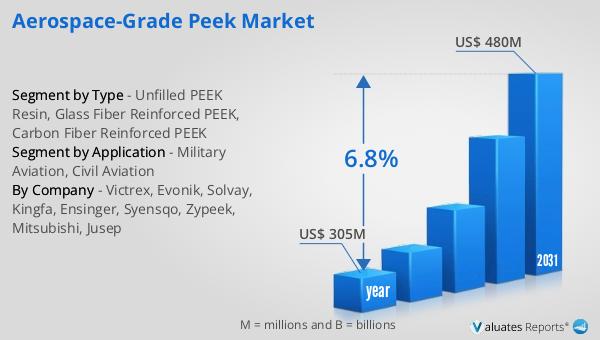

Global Aerospace-grade PEEK Market Outlook:

In 2024, the global market for aerospace-grade PEEK was valued at approximately $305 million. This market is anticipated to expand significantly, reaching an estimated value of $480 million by the year 2031. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The increasing demand for high-performance materials in the aerospace industry is a key driver of this growth, as manufacturers seek to enhance the efficiency and performance of aircraft through the use of advanced materials like PEEK. The market's expansion is also supported by ongoing research and development efforts aimed at improving the properties and applications of PEEK, as well as the broader trends within the aerospace industry towards innovation and sustainability. As the market continues to grow, it is expected to offer significant opportunities for manufacturers, suppliers, and other stakeholders within the aerospace industry, reflecting the increasing importance of high-performance materials in modern aircraft design and manufacturing.

| Report Metric | Details |

| Report Name | Aerospace-grade PEEK Market |

| Accounted market size in year | US$ 305 million |

| Forecasted market size in 2031 | US$ 480 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Victrex, Evonik, Solvay, Kingfa, Ensinger, Syensqo, Zypeek, Mitsubishi, Jusep |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |