What is Global Low Frequency Fatigue Testing Machine Market?

The Global Low Frequency Fatigue Testing Machine Market refers to the industry focused on machines designed to test the durability and longevity of materials and components under low-frequency cyclic loading. These machines are crucial in assessing how materials behave under repeated stress, which is essential for ensuring the safety and reliability of products across various industries. By simulating real-world conditions, these machines help manufacturers and researchers understand the fatigue life of materials, which is the number of cycles a material can withstand before failure. This market encompasses a range of machines that vary in size, capacity, and technology, catering to different testing needs. The demand for these machines is driven by the need for high-quality, durable products in sectors such as automotive, aerospace, and industrial manufacturing. As industries continue to innovate and develop new materials, the importance of fatigue testing machines in ensuring product safety and performance remains paramount. The market is characterized by technological advancements, with manufacturers focusing on enhancing machine capabilities to provide more accurate and efficient testing solutions.

Mechanical, Hydraulic, Electromechanical in the Global Low Frequency Fatigue Testing Machine Market:

The Global Low Frequency Fatigue Testing Machine Market is segmented based on the type of technology used in the machines, namely mechanical, hydraulic, and electromechanical systems. Mechanical fatigue testing machines are typically simpler in design and operation, relying on mechanical components to apply cyclic loads to test specimens. These machines are often used for basic fatigue testing applications where high precision is not a critical requirement. They are cost-effective and suitable for testing materials that do not require complex loading patterns. Hydraulic fatigue testing machines, on the other hand, use hydraulic power to apply loads. These machines are known for their high force capacity and are capable of testing large and heavy specimens. They are widely used in industries where high load testing is necessary, such as in the automotive and aerospace sectors. Hydraulic systems offer precise control over load application, making them ideal for testing materials that require accurate load simulation. Electromechanical fatigue testing machines utilize electric motors and mechanical components to apply cyclic loads. These machines are known for their precision and versatility, offering a wide range of testing capabilities. They are suitable for testing a variety of materials and components, from small specimens to larger structures. Electromechanical systems are often preferred in research and development settings due to their ability to provide detailed data and insights into material behavior. Each type of machine has its own advantages and limitations, and the choice of machine depends on the specific testing requirements and the nature of the materials being tested. As technology advances, manufacturers are continuously improving these machines to enhance their performance, accuracy, and efficiency, thereby meeting the evolving needs of various industries.

Automotive, Industrial Manufacturing, Aerospace, Research Institution, Others in the Global Low Frequency Fatigue Testing Machine Market:

The Global Low Frequency Fatigue Testing Machine Market finds applications across several key areas, including automotive, industrial manufacturing, aerospace, research institutions, and others. In the automotive industry, these machines are essential for testing the durability and performance of vehicle components such as suspension systems, chassis, and engine parts. By simulating real-world driving conditions, fatigue testing machines help manufacturers ensure that their vehicles can withstand the stresses of everyday use, thereby enhancing safety and reliability. In industrial manufacturing, fatigue testing machines are used to evaluate the performance of materials and components used in machinery and equipment. This is crucial for ensuring that industrial products can endure the demands of heavy-duty operations without failure. In the aerospace sector, fatigue testing is vital for assessing the structural integrity of aircraft components. Given the high safety standards in this industry, it is imperative to ensure that all parts can withstand the stresses of flight over extended periods. Research institutions utilize fatigue testing machines to study material properties and develop new materials with enhanced durability. These machines provide valuable data that can lead to innovations in material science and engineering. Other areas where fatigue testing machines are used include construction, where they help in evaluating the performance of building materials, and the energy sector, where they are used to test components used in power generation and distribution. Overall, the versatility and importance of fatigue testing machines make them indispensable tools in ensuring the safety, reliability, and performance of products across various industries.

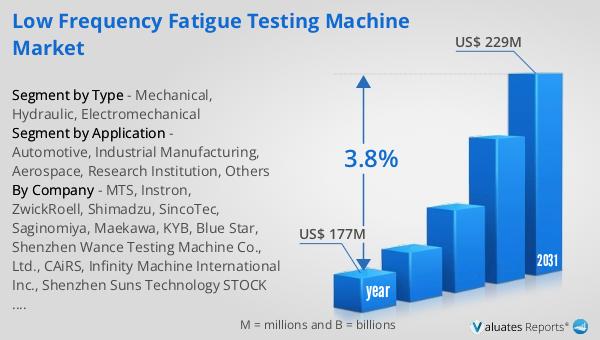

Global Low Frequency Fatigue Testing Machine Market Outlook:

In 2024, the global market for Low Frequency Fatigue Testing Machines was valued at approximately $177 million. Looking ahead, this market is expected to grow steadily, reaching an estimated value of $229 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.8% over the forecast period. The increasing demand for these machines is driven by the need for rigorous testing of materials and components across various industries to ensure their durability and reliability. As industries continue to innovate and develop new materials, the role of fatigue testing machines becomes even more critical in ensuring product safety and performance. The market's growth is also supported by technological advancements in testing machines, which enhance their capabilities and efficiency. Manufacturers are focusing on developing machines that offer more precise and accurate testing solutions, catering to the evolving needs of industries such as automotive, aerospace, and industrial manufacturing. As a result, the Global Low Frequency Fatigue Testing Machine Market is poised for steady growth, driven by the increasing emphasis on quality and safety in product development.

| Report Metric | Details |

| Report Name | Low Frequency Fatigue Testing Machine Market |

| Accounted market size in year | US$ 177 million |

| Forecasted market size in 2031 | US$ 229 million |

| CAGR | 3.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MTS, Instron, ZwickRoell, Shimadzu, SincoTec, Saginomiya, Maekawa, KYB, Blue Star, Shenzhen Wance Testing Machine Co., Ltd., CAiRS, Infinity Machine International Inc., Shenzhen Suns Technology STOCK Co., Ltd., Jinan Docer Testing Machine Technology Co., Ltd., Changchun KEXIN Testing Instrument Co., Ltd., Sinotest Equipment Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |