What is Global Electrified Monorail Conveyance Conveyor Market?

The Global Electrified Monorail Conveyance Conveyor Market refers to a specialized segment within the broader material handling industry, focusing on the use of electrified monorail systems for efficient transportation of goods. These systems are designed to move products along a fixed path using a single rail, powered by electricity, which makes them an eco-friendly alternative to traditional conveyor systems. The market is driven by the need for automation and efficiency in industries such as automotive, warehousing, logistics, and food and beverage. Electrified monorail systems offer several advantages, including reduced labor costs, increased safety, and improved operational efficiency. They are particularly beneficial in environments where space is limited, as they can be installed overhead, freeing up valuable floor space. The market is expected to grow as industries continue to seek innovative solutions to streamline operations and reduce their carbon footprint. As technology advances, these systems are becoming more sophisticated, with features such as real-time monitoring and integration with other automated systems, further enhancing their appeal to businesses looking to optimize their supply chain operations.

Overhead, Floor-Mounted in the Global Electrified Monorail Conveyance Conveyor Market:

In the realm of the Global Electrified Monorail Conveyance Conveyor Market, two primary configurations are prevalent: overhead and floor-mounted systems. Overhead electrified monorail systems are designed to transport goods above the ground, utilizing the ceiling space of a facility. This configuration is particularly advantageous in environments where floor space is at a premium, such as in densely packed warehouses or manufacturing plants. By elevating the conveyor system, businesses can maximize their use of available space, allowing for more efficient layout and workflow. Overhead systems also contribute to a safer working environment by reducing the risk of accidents associated with ground-level conveyors, such as tripping hazards or collisions with other equipment. Additionally, these systems can be integrated with other overhead infrastructure, such as lighting or HVAC systems, to further optimize facility operations. On the other hand, floor-mounted electrified monorail systems are installed at ground level and are often used in applications where overhead space is limited or where the transportation of heavy or bulky items is required. These systems are typically more robust and capable of handling larger loads compared to their overhead counterparts. Floor-mounted systems are commonly found in industries such as automotive manufacturing, where they are used to transport vehicle components along the production line. The flexibility of floor-mounted systems allows them to be configured in various layouts, including straight lines, curves, or loops, to accommodate the specific needs of a facility. Both overhead and floor-mounted electrified monorail systems offer unique benefits and can be tailored to meet the specific requirements of different industries. The choice between the two configurations often depends on factors such as available space, the nature of the goods being transported, and the overall layout of the facility. In some cases, businesses may opt for a combination of both systems to achieve the optimal balance of efficiency and flexibility. As the demand for automation and efficiency continues to grow across various industries, the adoption of electrified monorail systems is expected to increase, driving further innovation and development in this market segment. The integration of advanced technologies, such as IoT and AI, is also playing a significant role in the evolution of electrified monorail systems. These technologies enable real-time monitoring and data analysis, allowing businesses to optimize their operations and improve decision-making processes. For example, sensors can be used to track the movement of goods along the conveyor system, providing valuable insights into bottlenecks or inefficiencies. This data can then be used to make informed adjustments to the system, enhancing overall productivity and reducing downtime. Furthermore, the modular nature of electrified monorail systems allows for easy expansion or reconfiguration as business needs change. This flexibility is particularly beneficial in industries that experience fluctuations in demand or require frequent changes to their production processes. By investing in electrified monorail systems, businesses can future-proof their operations and remain competitive in an increasingly automated and fast-paced market. In conclusion, the Global Electrified Monorail Conveyance Conveyor Market offers a range of solutions for businesses seeking to improve their material handling operations. Whether through overhead or floor-mounted systems, these conveyors provide a reliable and efficient means of transporting goods, contributing to increased productivity and reduced operational costs. As technology continues to advance, the capabilities of electrified monorail systems will only expand, offering even greater opportunities for businesses to optimize their supply chain operations.

Automotive, Warehousing and Logistics, Food and Beverage, Others in the Global Electrified Monorail Conveyance Conveyor Market:

The Global Electrified Monorail Conveyance Conveyor Market finds extensive application across various industries, including automotive, warehousing and logistics, food and beverage, and others. In the automotive industry, electrified monorail systems are used to transport vehicle components along the production line, facilitating efficient assembly processes. These systems are particularly beneficial in automotive manufacturing plants, where they help streamline operations by reducing manual handling and minimizing the risk of damage to components. The ability to transport heavy and bulky items with ease makes electrified monorail systems an ideal choice for the automotive sector, where precision and efficiency are paramount. In the warehousing and logistics industry, electrified monorail systems play a crucial role in optimizing the movement of goods within distribution centers. These systems enable the efficient transportation of products from one area of the warehouse to another, reducing the need for manual labor and minimizing the risk of errors. By automating the movement of goods, businesses can improve their order fulfillment processes, reduce lead times, and enhance overall customer satisfaction. The flexibility of electrified monorail systems allows them to be easily integrated into existing warehouse layouts, making them a versatile solution for businesses looking to improve their logistics operations. The food and beverage industry also benefits from the use of electrified monorail systems, particularly in environments where hygiene and safety are critical. These systems can be designed to meet strict sanitation standards, ensuring that products are transported in a clean and controlled manner. In food processing plants, electrified monorail systems can be used to move raw materials, ingredients, and finished products between different stages of production, reducing the risk of contamination and ensuring consistent product quality. The ability to automate the transportation of goods also helps businesses in the food and beverage industry to increase their production capacity and reduce operational costs. Beyond these industries, electrified monorail systems are also used in a variety of other applications, including pharmaceuticals, electronics, and general manufacturing. In the pharmaceutical industry, for example, these systems can be used to transport sensitive materials in a controlled environment, ensuring compliance with regulatory requirements. In electronics manufacturing, electrified monorail systems can facilitate the movement of delicate components, reducing the risk of damage and improving production efficiency. The versatility and adaptability of electrified monorail systems make them a valuable asset for businesses across a wide range of industries, helping to drive innovation and improve operational performance. Overall, the Global Electrified Monorail Conveyance Conveyor Market offers a range of solutions for businesses seeking to enhance their material handling operations. By providing a reliable and efficient means of transporting goods, electrified monorail systems contribute to increased productivity, reduced operational costs, and improved safety across various industries. As businesses continue to seek innovative solutions to optimize their supply chain operations, the adoption of electrified monorail systems is expected to grow, driving further advancements in this market segment.

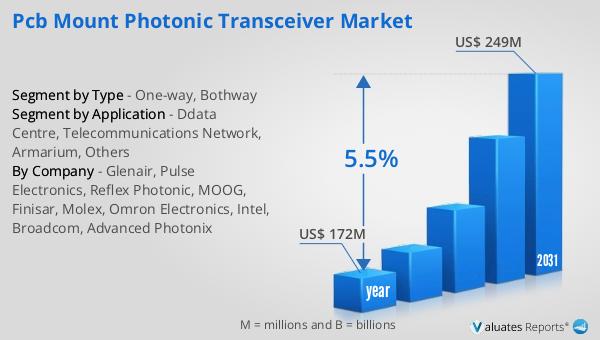

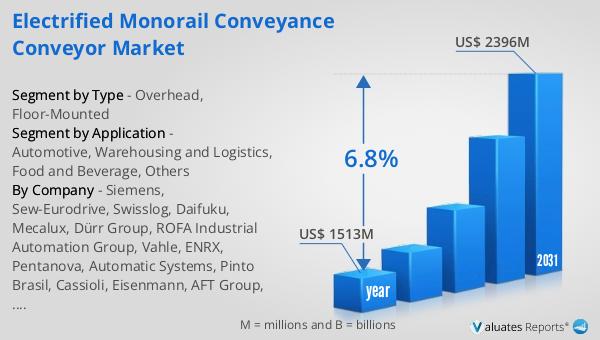

Global Electrified Monorail Conveyance Conveyor Market Outlook:

In 2024, the global market for Electrified Monorail Conveyance Conveyor was valued at approximately $1,513 million. Looking ahead, this market is anticipated to expand significantly, reaching an estimated size of $2,396 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The increasing demand for automation and efficiency in various industries is a key driver of this market expansion. As businesses strive to optimize their operations and reduce costs, the adoption of electrified monorail systems is expected to rise. These systems offer numerous advantages, including reduced labor costs, increased safety, and improved operational efficiency, making them an attractive option for businesses across different sectors. The integration of advanced technologies, such as IoT and AI, is also contributing to the growth of this market, enabling real-time monitoring and data analysis to enhance decision-making processes. As the market continues to evolve, businesses are likely to invest in electrified monorail systems to remain competitive and meet the demands of an increasingly automated and fast-paced market. This growth reflects the ongoing trend towards automation and the increasing importance of efficient material handling solutions in today's global economy.

| Report Metric | Details |

| Report Name | Electrified Monorail Conveyance Conveyor Market |

| Accounted market size in year | US$ 1513 million |

| Forecasted market size in 2031 | US$ 2396 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Siemens, Sew-Eurodrive, Swisslog, Daifuku, Mecalux, Dürr Group, ROFA Industrial Automation Group, Vahle, ENRX, Pentanova, Automatic Systems, Pinto Brasil, Cassioli, Eisenmann, AFT Group, Automag Conveyor Systems, Louis Schierholz, Central Conveyor (Tsubaki Group), FATA Automation, RBS Förderanlagen, LogSystems, OCC Systems, KM Tech, SFI, Fine Handling & Automation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |