What is Global Automatic Visual Inspection System Market?

The Global Automatic Visual Inspection System Market is a rapidly evolving sector that plays a crucial role in quality control across various industries. These systems are designed to automatically inspect products for defects or inconsistencies using advanced imaging technologies and software algorithms. By leveraging high-resolution cameras and sophisticated image processing, these systems can detect flaws that are often invisible to the human eye, ensuring that only products meeting the highest quality standards reach the market. This technology is particularly vital in industries such as electronics, automotive, and pharmaceuticals, where precision and reliability are paramount. The market for these systems is expanding as manufacturers increasingly recognize the benefits of automation in reducing human error, improving efficiency, and ensuring compliance with stringent quality standards. As a result, the demand for automatic visual inspection systems is expected to grow, driven by advancements in machine learning and artificial intelligence that enhance their accuracy and functionality. These systems not only help in maintaining product quality but also contribute to cost savings by minimizing waste and reducing the need for manual inspections. Overall, the Global Automatic Visual Inspection System Market is set to play an integral role in the future of manufacturing and quality assurance.

Front Inspection, Back Inspection in the Global Automatic Visual Inspection System Market:

Front Inspection and Back Inspection are two critical components of the Global Automatic Visual Inspection System Market, each serving distinct purposes in the quality control process. Front Inspection primarily focuses on examining the visible surfaces of a product, ensuring that the exterior meets the required standards of quality and aesthetics. This type of inspection is crucial in industries where the appearance of a product is as important as its functionality, such as consumer electronics and automotive manufacturing. By using high-resolution cameras and advanced image processing algorithms, Front Inspection systems can detect surface defects like scratches, dents, or discoloration, which could affect the product's marketability and customer satisfaction. On the other hand, Back Inspection delves deeper into the product, examining areas that are not immediately visible to the naked eye. This type of inspection is essential in sectors like semiconductor manufacturing, where internal defects can significantly impact the performance and reliability of the final product. Back Inspection systems utilize technologies such as X-ray imaging and 3D scanning to identify hidden flaws, such as voids, misalignments, or structural weaknesses, that could compromise the product's integrity. Both Front and Back Inspection systems are integral to the manufacturing process, ensuring that products not only look good but also function as intended. The integration of these systems into production lines helps manufacturers maintain high standards of quality while reducing the risk of costly recalls or customer complaints. As technology continues to advance, these inspection systems are becoming more sophisticated, offering greater accuracy and efficiency in detecting defects. The use of artificial intelligence and machine learning in these systems is further enhancing their capabilities, allowing for real-time analysis and decision-making. This not only speeds up the inspection process but also reduces the likelihood of human error, leading to more consistent and reliable results. In conclusion, Front and Back Inspection systems are vital components of the Global Automatic Visual Inspection System Market, providing manufacturers with the tools they need to ensure the highest levels of quality and reliability in their products.

SOT, SOD, SOP, QFN, DFN, Others in the Global Automatic Visual Inspection System Market:

The Global Automatic Visual Inspection System Market finds extensive application across various packaging types, including SOT (Small Outline Transistor), SOD (Small Outline Diode), SOP (Small Outline Package), QFN (Quad Flat No-leads), DFN (Dual Flat No-leads), and others. Each of these packaging types presents unique challenges and requirements for inspection, making the role of automatic visual inspection systems indispensable. In the case of SOT, which is commonly used in semiconductor devices, the inspection system must ensure that the leads are correctly aligned and free from defects that could affect the device's performance. Similarly, for SOD packages, the system must verify the integrity of the diode's encapsulation and the alignment of its leads. SOP packages, which are widely used in integrated circuits, require meticulous inspection to ensure that the pins are correctly positioned and that there are no soldering defects. The inspection system must also check for any surface defects or contamination that could impact the package's reliability. QFN and DFN packages, known for their compact size and high performance, present additional challenges due to their leadless design. The inspection system must be capable of detecting defects such as voids, misalignments, or delamination that could compromise the package's thermal and electrical performance. In addition to these specific packaging types, automatic visual inspection systems are also used in other areas, such as PCB (Printed Circuit Board) inspection, where they play a crucial role in ensuring the quality and reliability of electronic assemblies. By providing accurate and efficient inspection, these systems help manufacturers maintain high standards of quality while reducing the risk of defects and failures. The use of automatic visual inspection systems in these areas not only enhances product quality but also contributes to cost savings by minimizing waste and reducing the need for manual inspections. As technology continues to evolve, these systems are becoming more sophisticated, offering greater accuracy and efficiency in detecting defects. The integration of artificial intelligence and machine learning into these systems is further enhancing their capabilities, allowing for real-time analysis and decision-making. This not only speeds up the inspection process but also reduces the likelihood of human error, leading to more consistent and reliable results. In conclusion, the Global Automatic Visual Inspection System Market plays a vital role in ensuring the quality and reliability of various packaging types, providing manufacturers with the tools they need to meet the highest standards of quality and performance.

Global Automatic Visual Inspection System Market Outlook:

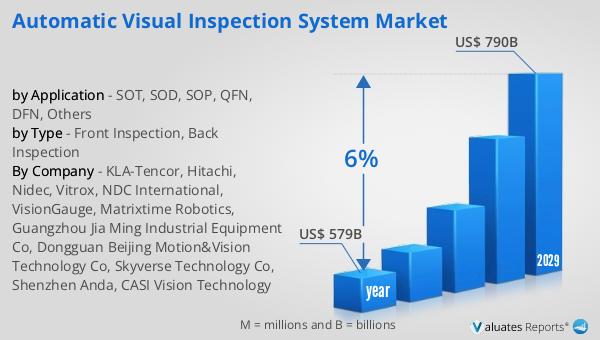

The global semiconductor market, valued at approximately $579 billion in 2022, is on a growth trajectory, with projections indicating it could reach around $790 billion by 2029. This anticipated growth reflects a compound annual growth rate (CAGR) of 6% over the forecast period. This expansion is driven by several factors, including the increasing demand for semiconductors in various applications such as consumer electronics, automotive, and telecommunications. As technology continues to advance, the need for more sophisticated and efficient semiconductor components is rising, fueling the market's growth. Additionally, the proliferation of emerging technologies such as artificial intelligence, the Internet of Things (IoT), and 5G connectivity is further boosting the demand for semiconductors. These technologies require advanced semiconductor solutions to support their complex functionalities, driving innovation and development within the industry. Moreover, the growing trend towards automation and digitalization across various sectors is also contributing to the market's expansion. As industries increasingly adopt smart technologies and automated systems, the demand for semiconductors is expected to rise, supporting the market's growth. Overall, the global semiconductor market is poised for significant growth in the coming years, driven by technological advancements and increasing demand across various applications.

| Report Metric | Details |

| Report Name | Automatic Visual Inspection System Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KLA-Tencor, Hitachi, Nidec, Vitrox, NDC International, VisionGauge, Matrixtime Robotics, Guangzhou Jia Ming Industrial Equipment Co, Dongguan Beijing Motion&Vision Technology Co, Skyverse Technology Co, Shenzhen Anda, CASI Vision Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |