What is Global Piezoelectric Thin Film Device Market?

The Global Piezoelectric Thin Film Device Market is a rapidly evolving sector that plays a crucial role in various industries due to its unique properties. Piezoelectric thin film devices are specialized materials that generate an electric charge in response to mechanical stress. These devices are integral in applications requiring precise control and sensitivity, such as sensors, actuators, and energy harvesting systems. The market for these devices is driven by the increasing demand for miniaturized electronic components and the growing adoption of smart technologies across different sectors. The versatility of piezoelectric thin films allows them to be used in a wide range of applications, from consumer electronics to healthcare and automotive industries. As technology advances, the capabilities of these devices continue to expand, offering new opportunities for innovation and efficiency improvements. The global market is characterized by ongoing research and development efforts aimed at enhancing the performance and durability of piezoelectric materials, which in turn fuels market growth. With the continuous push towards more sustainable and efficient technologies, the piezoelectric thin film device market is poised for significant advancements in the coming years.

Sol-Gel, PVD in the Global Piezoelectric Thin Film Device Market:

Sol-Gel and Physical Vapor Deposition (PVD) are two prominent techniques used in the fabrication of piezoelectric thin film devices, each offering distinct advantages and challenges. The Sol-Gel process is a chemical method that involves the transition of a solution into a solid gel phase. This technique is highly valued for its ability to produce uniform and high-purity thin films. In the context of piezoelectric thin films, Sol-Gel is particularly advantageous due to its cost-effectiveness and the ability to coat complex shapes and large areas. The process begins with the preparation of a precursor solution, which is then deposited onto a substrate. As the solvent evaporates, a gel-like film forms, which is subsequently heat-treated to achieve the desired crystalline structure. This method allows for precise control over the film's composition and thickness, making it ideal for applications requiring high precision and performance. However, the Sol-Gel process can be time-consuming and may require multiple coating and annealing steps to achieve the desired film properties. On the other hand, Physical Vapor Deposition (PVD) is a vacuum-based technique that involves the physical transfer of material from a source to a substrate. PVD is renowned for its ability to produce thin films with excellent adhesion and uniformity. In the piezoelectric thin film device market, PVD is often preferred for its ability to deposit films with high density and low defect rates. The process typically involves the evaporation or sputtering of a target material, which then condenses onto the substrate to form a thin film. PVD offers several advantages, including the ability to deposit a wide range of materials, high deposition rates, and the capability to produce films with complex compositions. Additionally, PVD processes can be easily scaled up for industrial production, making them suitable for large-scale manufacturing of piezoelectric devices. However, PVD systems can be expensive to set up and operate, and the process may require high temperatures, which can limit the choice of substrate materials. Both Sol-Gel and PVD techniques are integral to the development of piezoelectric thin film devices, each offering unique benefits that cater to different application requirements. The choice between these methods often depends on the specific needs of the application, such as the desired film properties, production scale, and cost considerations. As the demand for advanced piezoelectric devices continues to grow, ongoing research and development efforts are focused on optimizing these fabrication techniques to enhance the performance and reliability of the resulting thin films. Innovations in Sol-Gel and PVD processes are expected to play a crucial role in advancing the capabilities of piezoelectric thin film devices, enabling new applications and driving market growth. The synergy between these fabrication methods and the evolving needs of various industries underscores the dynamic nature of the global piezoelectric thin film device market.

Healthcare, Consumer Electronics, Aerospace and Defense, Others in the Global Piezoelectric Thin Film Device Market:

The Global Piezoelectric Thin Film Device Market finds extensive applications across various sectors, each leveraging the unique properties of these devices to enhance performance and efficiency. In the healthcare industry, piezoelectric thin film devices are pivotal in the development of advanced medical sensors and diagnostic equipment. These devices are used in ultrasound imaging, where their ability to convert electrical signals into mechanical vibrations and vice versa is crucial for producing high-resolution images. Additionally, piezoelectric sensors are employed in wearable health monitoring devices, providing real-time data on vital signs such as heart rate and respiratory rate. The precision and sensitivity of piezoelectric thin films make them ideal for applications requiring accurate and reliable measurements, contributing to improved patient outcomes and more efficient healthcare delivery. In the realm of consumer electronics, piezoelectric thin film devices are integral to the development of compact and efficient components. These devices are used in microphones, speakers, and touch sensors, where their ability to convert mechanical energy into electrical signals enhances the functionality and performance of electronic gadgets. The miniaturization of electronic components is a key trend in the consumer electronics industry, and piezoelectric thin films play a crucial role in enabling this trend by offering high performance in a small form factor. As consumer demand for smarter and more efficient devices continues to grow, the adoption of piezoelectric thin film technology is expected to increase, driving innovation and market expansion. In the aerospace and defense sectors, piezoelectric thin film devices are employed in a variety of applications, from vibration control systems to precision navigation equipment. The ability of piezoelectric materials to withstand extreme conditions and provide accurate measurements makes them ideal for use in aircraft and defense systems. In aerospace, piezoelectric sensors are used for structural health monitoring, providing real-time data on the condition of aircraft components and helping to ensure safety and reliability. In defense, piezoelectric devices are used in sonar systems and precision-guided munitions, where their ability to convert sound waves into electrical signals is crucial for accurate targeting and detection. The robustness and reliability of piezoelectric thin films make them indispensable in these high-stakes applications, where performance and precision are paramount. Beyond these sectors, piezoelectric thin film devices are also used in a variety of other applications, including automotive systems, energy harvesting, and industrial automation. In the automotive industry, piezoelectric sensors are used for engine monitoring and control, providing real-time data on parameters such as pressure and temperature. In energy harvesting, piezoelectric thin films are used to convert mechanical energy from vibrations and movements into electrical energy, offering a sustainable solution for powering small electronic devices. In industrial automation, piezoelectric actuators are used for precise control of machinery and equipment, enhancing efficiency and productivity. The versatility and adaptability of piezoelectric thin film devices make them valuable across a wide range of applications, driving their adoption and market growth. As industries continue to seek innovative solutions to enhance performance and efficiency, the demand for piezoelectric thin film devices is expected to rise, underscoring their importance in the global market.

Global Piezoelectric Thin Film Device Market Outlook:

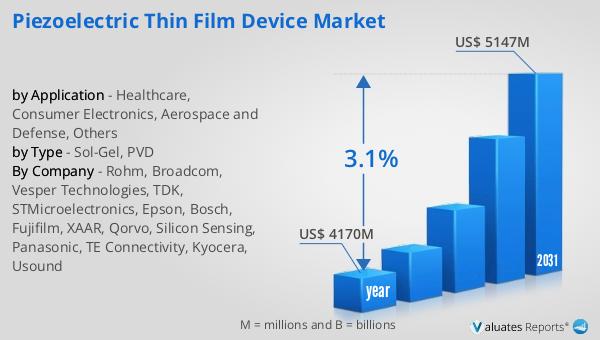

The global market for Piezoelectric Thin Film Devices was valued at approximately $4.17 billion in 2024, with projections indicating a growth trajectory that will see it reach around $5.147 billion by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 3.1% over the forecast period. This steady growth reflects the increasing demand for piezoelectric thin film devices across various industries, driven by their unique properties and versatile applications. The market's expansion is fueled by advancements in technology and the growing adoption of smart devices and systems that rely on piezoelectric components for enhanced performance and efficiency. As industries continue to innovate and integrate these devices into their products and processes, the market is poised for sustained growth. The projected increase in market size underscores the importance of piezoelectric thin film devices in modern technology and their potential to drive further advancements in various sectors. With ongoing research and development efforts focused on improving the performance and capabilities of these devices, the global piezoelectric thin film device market is set to play a pivotal role in shaping the future of technology and industry.

| Report Metric | Details |

| Report Name | Piezoelectric Thin Film Device Market |

| Accounted market size in year | US$ 4170 million |

| Forecasted market size in 2031 | US$ 5147 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rohm, Broadcom, Vesper Technologies, TDK, STMicroelectronics, Epson, Bosch, Fujifilm, XAAR, Qorvo, Silicon Sensing, Panasonic, TE Connectivity, Kyocera, Usound |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |