What is Global High-pressure Gas Cylinders Market?

The Global High-pressure Gas Cylinders Market is a dynamic and essential segment of the industrial landscape, catering to a wide range of applications that require the storage and transportation of gases under high pressure. These cylinders are crucial for industries such as healthcare, automotive, and manufacturing, where gases like oxygen, nitrogen, and hydrogen are frequently used. High-pressure gas cylinders are designed to withstand extreme conditions, ensuring the safe and efficient containment of gases. They are typically made from materials like steel and aluminum, which provide the necessary strength and durability. The market for these cylinders is driven by the increasing demand for industrial gases, advancements in healthcare technologies, and the growing adoption of alternative fuel vehicles. As industries continue to expand and innovate, the need for reliable and safe gas storage solutions becomes even more critical. This market is characterized by continuous technological advancements aimed at improving the safety, efficiency, and environmental impact of gas cylinders. With a focus on sustainability and safety, the Global High-pressure Gas Cylinders Market is poised for significant growth, adapting to the evolving needs of various industries worldwide.

Steel Type, Aluminum Type, Others in the Global High-pressure Gas Cylinders Market:

In the Global High-pressure Gas Cylinders Market, the materials used for manufacturing these cylinders play a crucial role in determining their performance, safety, and application suitability. Steel type cylinders are among the most commonly used due to their robustness and ability to withstand high pressures. Steel cylinders are favored in industries where durability and strength are paramount, such as in industrial gas applications. They are known for their resistance to impact and ability to handle a wide range of gases, making them versatile for various industrial uses. However, steel cylinders are relatively heavy, which can be a limitation in applications where weight is a critical factor. On the other hand, aluminum type cylinders offer a lightweight alternative to steel. These cylinders are particularly advantageous in applications where portability and ease of handling are important, such as in medical and recreational uses. Aluminum cylinders are also resistant to corrosion, which enhances their longevity and reliability in different environments. Despite being lighter, they maintain a high level of strength and can safely contain gases at high pressures. The choice between steel and aluminum cylinders often depends on the specific requirements of the application, including factors like weight, cost, and environmental conditions. In addition to steel and aluminum, there are other materials used in the manufacturing of high-pressure gas cylinders, each offering unique benefits. Composite materials, for example, are increasingly being used due to their lightweight nature and high strength-to-weight ratio. These materials are often a combination of fibers and resins, providing excellent resistance to corrosion and impact. Composite cylinders are particularly popular in applications where weight reduction is crucial, such as in aerospace and automotive industries. They also offer enhanced safety features, as they are less prone to catastrophic failure compared to traditional materials. However, composite cylinders can be more expensive to produce, which may limit their use in cost-sensitive applications. Another category within the "others" segment includes cylinders made from specialty alloys and polymers. These materials are used in niche applications where specific chemical resistance or temperature tolerance is required. For instance, certain polymers can be used in environments where exposure to harsh chemicals is a concern, providing a safe and reliable gas storage solution. The choice of material in the Global High-pressure Gas Cylinders Market is influenced by a variety of factors, including the type of gas being stored, the intended application, and the environmental conditions. Manufacturers continue to innovate and develop new materials to meet the evolving demands of the market, focusing on enhancing safety, reducing weight, and improving the overall performance of gas cylinders. As industries continue to evolve and new applications for high-pressure gas cylinders emerge, the diversity of materials used in their production is likely to expand, offering even more tailored solutions for specific needs.

Industrial Gas, Natural Gas, Fire Gas, Others in the Global High-pressure Gas Cylinders Market:

The usage of Global High-pressure Gas Cylinders Market spans across various sectors, each with its unique requirements and applications. In the industrial gas sector, high-pressure gas cylinders are indispensable for storing and transporting gases like oxygen, nitrogen, and argon, which are essential for processes such as welding, cutting, and chemical manufacturing. These cylinders ensure that gases are delivered safely and efficiently to where they are needed, supporting a wide range of industrial activities. The reliability and durability of high-pressure gas cylinders make them a preferred choice in industrial settings, where safety and performance are paramount. In the natural gas sector, high-pressure gas cylinders are used for storing and transporting compressed natural gas (CNG), which is increasingly being adopted as an alternative fuel for vehicles. CNG is considered a cleaner and more environmentally friendly option compared to traditional fossil fuels, and high-pressure gas cylinders play a crucial role in its storage and distribution. These cylinders are designed to withstand the high pressures required to compress natural gas, ensuring safe and efficient fuel delivery for vehicles. The use of CNG cylinders is particularly prevalent in regions where there is a strong push towards reducing carbon emissions and promoting sustainable energy solutions. Fire gas applications also rely heavily on high-pressure gas cylinders, particularly in firefighting and emergency response scenarios. Cylinders containing gases like carbon dioxide and nitrogen are used in fire suppression systems to quickly and effectively extinguish fires. These systems are critical in protecting lives and property, and the reliability of high-pressure gas cylinders is essential in ensuring their effectiveness. In addition to firefighting, these cylinders are also used in rescue operations, providing breathable air to firefighters and emergency personnel in hazardous environments. The versatility and reliability of high-pressure gas cylinders make them an invaluable tool in emergency response situations. Beyond these specific sectors, high-pressure gas cylinders find applications in a variety of other areas, including healthcare, food and beverage, and aerospace. In healthcare, cylinders are used to store medical gases like oxygen and nitrous oxide, which are vital for patient care and surgical procedures. The food and beverage industry uses high-pressure gas cylinders for carbonation and preservation processes, ensuring product quality and safety. In aerospace, these cylinders are used for storing gases required for propulsion and life support systems. The diverse applications of high-pressure gas cylinders highlight their importance across multiple industries, each with its unique set of requirements and challenges. As technology advances and new applications emerge, the demand for high-pressure gas cylinders is expected to grow, driven by the need for safe, efficient, and reliable gas storage solutions.

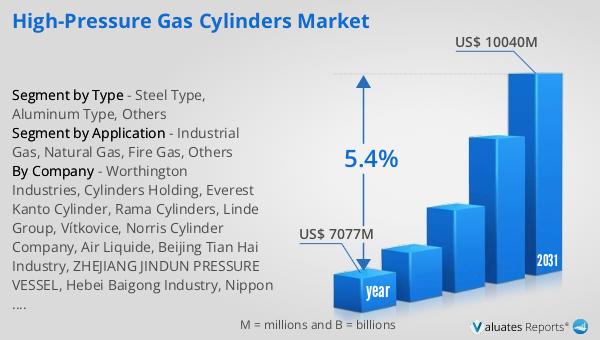

Global High-pressure Gas Cylinders Market Outlook:

The global market for high-pressure gas cylinders was valued at $7,077 million in 2024 and is anticipated to expand to a revised size of $10,040 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. North America holds a leading position in this market, accounting for 35% of the global share, supported by its robust industrial base, advanced healthcare systems, and the increasing adoption of alternative fuel vehicles. Europe follows with a 29% share, driven by stringent environmental regulations and decarbonization initiatives. Meanwhile, China accounts for 20% of the market, underpinned by its large-scale industrial production and growing energy diversification efforts. On the application side, industrial gas remains the largest end-use segment, constituting approximately 59% of global demand. This significant demand is fueled by the widespread use of industrial gases in various manufacturing and processing industries. The market dynamics are shaped by regional industrial activities, regulatory frameworks, and technological advancements, all of which contribute to the evolving landscape of the high-pressure gas cylinders market. As industries continue to innovate and expand, the demand for reliable and efficient gas storage solutions is expected to drive further growth in this market.

| Report Metric | Details |

| Report Name | High-pressure Gas Cylinders Market |

| Accounted market size in year | US$ 7077 million |

| Forecasted market size in 2031 | US$ 10040 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Worthington Industries, Cylinders Holding, Everest Kanto Cylinder, Rama Cylinders, Linde Group, Vítkovice, Norris Cylinder Company, Air Liquide, Beijing Tian Hai Industry, ZHEJIANG JINDUN PRESSURE VESSEL, Hebei Baigong Industry, Nippon Sanso, NK Co., Ltd., Sinoma Science and Technology, Messer, Shandong Yongan Special Equipment, Shandong Hualing Electronics, Jai Maruti Gas Cylinders Ltd., Faber Industrie, Gelest, MSA Safety, Anhui Clean Energy, Luxfer Group, Hexagon Agility |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |