What is Global API Pumps Market?

The Global API Pumps Market refers to the worldwide industry focused on the production and distribution of pumps that adhere to the American Petroleum Institute (API) standards. These pumps are specifically designed to meet the rigorous demands of industries such as oil and gas, chemical processing, and others that require high levels of reliability, efficiency, and safety. API pumps are engineered to handle a variety of fluids, including those that are corrosive, abrasive, or contain solids, making them essential components in many industrial processes. The market encompasses a range of pump types, including centrifugal and positive displacement pumps, each tailored to specific applications and operational requirements. As industries continue to expand and modernize, the demand for API-compliant pumps is expected to grow, driven by the need for equipment that can withstand harsh operating conditions and deliver consistent performance. The market is characterized by technological advancements, with manufacturers focusing on improving pump efficiency, reducing energy consumption, and enhancing durability. This global market is also influenced by regulatory standards and environmental considerations, as companies strive to minimize their ecological footprint while maintaining operational excellence.

Overhung Pump, Between Bearing Pump, Others in the Global API Pumps Market:

In the Global API Pumps Market, there are several types of pumps, each designed to meet specific industrial needs. Overhung pumps are a common type, characterized by their design where the impeller is mounted on the end of a shaft, supported by bearings on one side only. This design allows for easy maintenance and is typically used in applications where space is limited. Overhung pumps are versatile and can handle a wide range of fluids, making them suitable for various industries, including oil and gas, chemical processing, and water treatment. They are known for their efficiency and reliability, often used in situations where downtime must be minimized. Between bearing pumps, on the other hand, have the impeller supported by bearings on both sides, providing greater stability and allowing them to handle higher pressures and flow rates. This makes them ideal for heavy-duty applications, such as in refineries and petrochemical plants, where robust performance is critical. Between bearing pumps are often used in situations where the fluid being pumped is particularly challenging, such as those with high temperatures or corrosive properties. Other types of pumps in the API market include vertical pumps and specialty pumps, each designed for specific applications. Vertical pumps are often used in situations where space is constrained, as they have a smaller footprint compared to horizontal pumps. They are commonly used in water treatment and cooling tower applications. Specialty pumps, meanwhile, are designed for unique or challenging applications, such as handling slurries or highly viscous fluids. These pumps are often customized to meet the specific needs of a particular process or industry. The Global API Pumps Market is diverse, with a wide range of pump types available to meet the varied needs of industries worldwide. Manufacturers continue to innovate, developing new designs and materials to improve pump performance and extend their lifespan. As industries evolve and new challenges arise, the demand for specialized and high-performance pumps is expected to grow, driving further advancements in the market.

Oil and Gas, Chemical, Others in the Global API Pumps Market:

The Global API Pumps Market plays a crucial role in several key industries, including oil and gas, chemical processing, and others. In the oil and gas sector, API pumps are essential for a variety of applications, from upstream exploration and production to downstream refining and distribution. These pumps are designed to handle the demanding conditions of the oil and gas industry, including high pressures, extreme temperatures, and corrosive fluids. They are used in processes such as crude oil transportation, gas processing, and refining, where reliability and efficiency are paramount. In the chemical industry, API pumps are used to transport a wide range of chemicals, including acids, bases, and solvents. These pumps must be able to handle corrosive and abrasive fluids, as well as those with varying viscosities. The chemical industry relies on API pumps for processes such as chemical synthesis, mixing, and separation, where precise control and consistent performance are essential. Other industries that utilize API pumps include water and wastewater treatment, power generation, and food and beverage processing. In water treatment, API pumps are used to transport and treat water, ensuring safe and reliable water supply. In power generation, they are used in cooling systems and for fuel handling, where efficiency and reliability are critical. In the food and beverage industry, API pumps are used to transport ingredients and finished products, where hygiene and safety are of utmost importance. The versatility and reliability of API pumps make them indispensable in these industries, where they contribute to operational efficiency and safety. As industries continue to grow and evolve, the demand for high-performance API pumps is expected to increase, driving further innovation and development in the market.

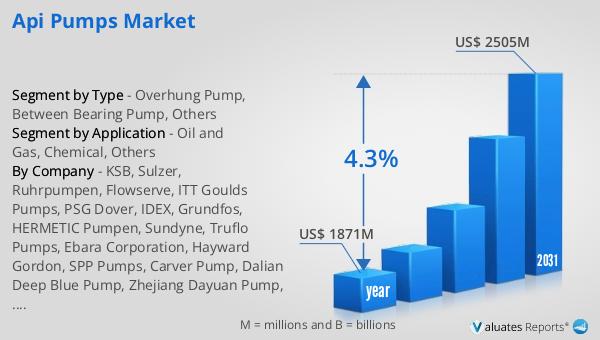

Global API Pumps Market Outlook:

The global market for API Pumps was valued at US$ 1871 million in the year 2024 and is projected to reach a revised size of US$ 2505 million by 2031, growing at a compound annual growth rate (CAGR) of 4.3% during the forecast period. This growth reflects the increasing demand for API-compliant pumps across various industries, driven by the need for reliable and efficient equipment that can withstand harsh operating conditions. The market's expansion is also influenced by technological advancements, as manufacturers focus on developing pumps that offer improved performance, energy efficiency, and durability. As industries such as oil and gas, chemical processing, and others continue to expand and modernize, the demand for API pumps is expected to grow, supporting the market's positive outlook. The projected growth of the API Pumps Market highlights the importance of these pumps in industrial processes, where they play a critical role in ensuring operational efficiency and safety. As companies strive to meet regulatory standards and environmental considerations, the demand for high-performance API pumps is likely to increase, driving further innovation and development in the market.

| Report Metric | Details |

| Report Name | API Pumps Market |

| Accounted market size in year | US$ 1871 million |

| Forecasted market size in 2031 | US$ 2505 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KSB, Sulzer, Ruhrpumpen, Flowserve, ITT Goulds Pumps, PSG Dover, IDEX, Grundfos, HERMETIC Pumpen, Sundyne, Truflo Pumps, Ebara Corporation, Hayward Gordon, SPP Pumps, Carver Pump, Dalian Deep Blue Pump, Zhejiang Dayuan Pump, Source Pumps & Systems, V-FLO Pumps & System, Liancheng Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |