What is Global 300mm Wafer Used Electrostatic Chuck Market?

The Global 300mm Wafer Used Electrostatic Chuck Market is a specialized segment within the semiconductor industry, focusing on the production and utilization of electrostatic chucks (ESCs) designed for 300mm wafers. These chucks are crucial components in semiconductor manufacturing, as they securely hold silicon wafers in place during various processing steps. The 300mm wafer size is significant because it allows for more efficient production, reducing costs and increasing output. Electrostatic chucks use electrostatic forces to grip the wafer, providing a stable and uniform platform for processes like etching, deposition, and ion implantation. This market is driven by the growing demand for advanced semiconductor devices, which require precise and reliable manufacturing techniques. As technology continues to evolve, the need for high-quality ESCs in the production of 300mm wafers is expected to rise, making this market an essential part of the semiconductor supply chain. The market's growth is also influenced by advancements in materials and design, which enhance the performance and durability of electrostatic chucks, ensuring they meet the stringent requirements of modern semiconductor fabrication.

Alumina Electrostatic Chuck, Aluminum Nitride Electrostatic Chuck, Silicon Carbide Electrostatic Chuck, Polyimide Electrostatic Chuck in the Global 300mm Wafer Used Electrostatic Chuck Market:

Alumina Electrostatic Chucks are a popular choice in the Global 300mm Wafer Used Electrostatic Chuck Market due to their excellent thermal and electrical insulating properties. Made from aluminum oxide, these chucks are highly resistant to wear and corrosion, making them ideal for use in harsh semiconductor processing environments. They provide a stable platform for wafer processing, ensuring precise control over temperature and electrical conductivity. Aluminum Nitride Electrostatic Chucks, on the other hand, offer superior thermal conductivity compared to alumina chucks. This makes them particularly suitable for processes that require rapid heat dissipation, such as high-temperature etching and deposition. Aluminum nitride chucks are also known for their excellent mechanical strength and resistance to thermal shock, which enhances their durability and performance in demanding applications. Silicon Carbide Electrostatic Chucks are renowned for their exceptional hardness and thermal stability. These chucks are often used in processes that involve high temperatures and aggressive chemicals, as they can withstand extreme conditions without degrading. Silicon carbide's high thermal conductivity also helps maintain uniform temperature distribution across the wafer, which is critical for achieving consistent processing results. Polyimide Electrostatic Chucks are valued for their flexibility and chemical resistance. Made from a high-performance polymer, these chucks are lightweight and can be easily customized to meet specific application requirements. Polyimide chucks are particularly useful in processes that involve frequent temperature cycling, as they can accommodate thermal expansion and contraction without cracking or warping. Each type of electrostatic chuck offers unique advantages, allowing manufacturers to select the most appropriate material based on the specific needs of their semiconductor fabrication processes. As the demand for advanced semiconductor devices continues to grow, the development and optimization of these materials will play a crucial role in the evolution of the Global 300mm Wafer Used Electrostatic Chuck Market.

Etching Process, PVD Process, CVD Process, Ion Implantation Process, Others in the Global 300mm Wafer Used Electrostatic Chuck Market:

The Global 300mm Wafer Used Electrostatic Chuck Market plays a vital role in various semiconductor manufacturing processes, including etching, physical vapor deposition (PVD), chemical vapor deposition (CVD), ion implantation, and others. In the etching process, electrostatic chucks are used to hold the wafer securely in place while precise patterns are etched onto its surface. This process requires high precision and stability, as any movement or misalignment can result in defects. Electrostatic chucks provide the necessary stability and uniformity, ensuring that the etching process is carried out with high accuracy. In the PVD process, electrostatic chucks are used to maintain the wafer's position during the deposition of thin films. The chucks' ability to provide uniform temperature distribution and electrical conductivity is crucial for achieving consistent film thickness and quality. Similarly, in the CVD process, electrostatic chucks are used to hold the wafer in place while gaseous reactants are deposited onto its surface to form thin films. The chucks' thermal and chemical resistance ensures that they can withstand the harsh conditions of the CVD process without degrading. In the ion implantation process, electrostatic chucks are used to secure the wafer as ions are accelerated and implanted into its surface. This process requires precise control over the wafer's position and temperature, which electrostatic chucks provide. Additionally, electrostatic chucks are used in other semiconductor manufacturing processes, such as wafer cleaning and inspection, where their ability to hold the wafer securely and provide uniform temperature distribution is essential. The versatility and reliability of electrostatic chucks make them indispensable in the production of advanced semiconductor devices, driving the growth of the Global 300mm Wafer Used Electrostatic Chuck Market.

Global 300mm Wafer Used Electrostatic Chuck Market Outlook:

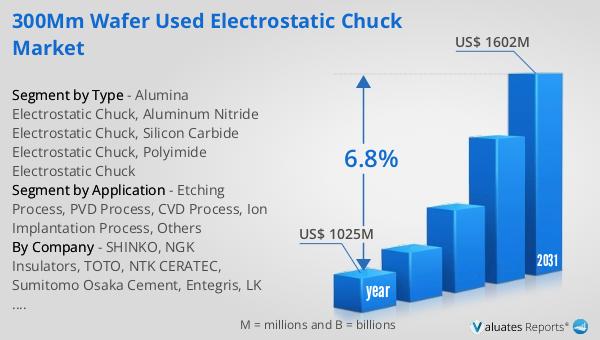

The global market for 300mm Wafer Used Electrostatic Chuck was valued at $1,025 million in 2024 and is anticipated to expand to a revised size of $1,602 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.8% over the forecast period. This market is characterized by a high level of concentration, with the top four global manufacturers commanding over 70% of the total market share. This concentration indicates a competitive landscape where a few key players dominate, leveraging their technological expertise and extensive production capabilities to maintain their market positions. The growth in this market is driven by the increasing demand for advanced semiconductor devices, which require precise and reliable manufacturing processes. As the semiconductor industry continues to evolve, the need for high-quality electrostatic chucks in the production of 300mm wafers is expected to rise. This growth is further supported by advancements in materials and design, which enhance the performance and durability of electrostatic chucks, ensuring they meet the stringent requirements of modern semiconductor fabrication. The market's expansion reflects the critical role that electrostatic chucks play in the semiconductor supply chain, providing the stability and precision needed for the production of cutting-edge semiconductor devices.

| Report Metric | Details |

| Report Name | 300mm Wafer Used Electrostatic Chuck Market |

| Accounted market size in year | US$ 1025 million |

| Forecasted market size in 2031 | US$ 1602 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SHINKO, NGK Insulators, TOTO, NTK CERATEC, Sumitomo Osaka Cement, Entegris, LK ENGINEERING, MiCo, Technetics Group, Creative Technology Corporation, Kyocera, Krosaki Harima Corporation, TOMOEGAWA, AEGISCO, Hebei Sinopack Electronic, Coherent, Beijing U-PRECISION TECH, Tsukuba Seiko |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |