What is Global Directly Buried Insulated Pipes Market?

The Global Directly Buried Insulated Pipes Market refers to the industry focused on the production and distribution of insulated pipes that are installed underground. These pipes are designed to transport fluids such as water, oil, and gas while maintaining the temperature of the contents, thus improving energy efficiency and reducing heat loss. The insulation is crucial as it helps in minimizing energy consumption and maintaining the integrity of the transported materials over long distances. This market is driven by the increasing demand for energy-efficient solutions in various sectors, including residential, commercial, and industrial applications. The growth in urbanization and industrialization across the globe has led to a rise in infrastructure development, which in turn boosts the demand for these insulated pipes. Additionally, stringent government regulations regarding energy conservation and the reduction of carbon emissions further propel the market's expansion. The market encompasses various types of insulated pipes, each designed to meet specific requirements and conditions, ensuring optimal performance and durability in diverse environments.

Plastic Sheathed Steel Insulation Pipe, Steel Outer Protective Pipe Vacuum Composite Insulation Prefabricated Direct Buried Pipe, Steel Jacketed Steel Insulation Pipe in the Global Directly Buried Insulated Pipes Market:

Plastic Sheathed Steel Insulation Pipe, Steel Outer Protective Pipe Vacuum Composite Insulation Prefabricated Direct Buried Pipe, and Steel Jacketed Steel Insulation Pipe are key components within the Global Directly Buried Insulated Pipes Market. The Plastic Sheathed Steel Insulation Pipe is characterized by its robust construction, featuring a steel pipe core encased in a plastic sheath. This design offers excellent protection against corrosion and mechanical damage, making it ideal for use in harsh environments. The plastic sheath acts as a barrier, preventing moisture ingress and ensuring the longevity of the pipe. This type of pipe is commonly used in applications where durability and resistance to external factors are paramount. On the other hand, the Steel Outer Protective Pipe Vacuum Composite Insulation Prefabricated Direct Buried Pipe is a sophisticated solution that combines multiple layers of insulation with a vacuum-sealed outer steel casing. This design significantly enhances thermal efficiency by minimizing heat loss, making it suitable for transporting high-temperature fluids over long distances. The vacuum layer acts as an additional insulator, further reducing energy consumption and operational costs. This type of pipe is often employed in industries where maintaining precise temperature control is critical, such as in chemical processing and district heating systems. Lastly, the Steel Jacketed Steel Insulation Pipe is a robust and versatile option that features a steel pipe encased within another steel jacket. This design provides superior mechanical strength and protection against external impacts, making it suitable for use in areas with high mechanical stress or potential for physical damage. The insulation material between the two steel layers ensures efficient thermal performance, making it ideal for applications in the oil and gas industry, where transporting fluids at consistent temperatures is essential. Each of these pipe types plays a crucial role in the Global Directly Buried Insulated Pipes Market, catering to diverse industry needs and contributing to the overall growth and development of the market.

Heating, Petroleum and Natural Gas, Chemical Industry, Electric Power, Others in the Global Directly Buried Insulated Pipes Market:

The usage of Global Directly Buried Insulated Pipes Market spans several critical areas, including heating, petroleum and natural gas, the chemical industry, electric power, and others. In the heating sector, these insulated pipes are essential for district heating systems, where they transport hot water or steam from central heating plants to residential and commercial buildings. The insulation ensures minimal heat loss during transit, enhancing energy efficiency and reducing operational costs. This is particularly important in regions with harsh winters, where maintaining consistent indoor temperatures is crucial for comfort and safety. In the petroleum and natural gas industry, directly buried insulated pipes are used to transport oil and gas from extraction sites to processing facilities and distribution networks. The insulation helps maintain the temperature and viscosity of the fluids, preventing blockages and ensuring smooth flow. This is vital for optimizing production efficiency and minimizing energy consumption. In the chemical industry, these pipes are used to transport various chemicals and process fluids that require precise temperature control. The insulation ensures that the fluids remain at the desired temperature, preventing chemical reactions that could compromise product quality or safety. This is particularly important in processes that involve temperature-sensitive materials or reactions. In the electric power sector, directly buried insulated pipes are used in cooling systems for power plants, where they transport cooling water to and from the plant. The insulation helps maintain the temperature of the cooling water, ensuring efficient heat exchange and preventing overheating of critical equipment. This is essential for maintaining the reliability and efficiency of power generation operations. Additionally, these pipes are used in other applications, such as in the food and beverage industry, where they transport temperature-sensitive ingredients and products. The versatility and efficiency of directly buried insulated pipes make them an indispensable component in various industries, driving their demand and contributing to the growth of the Global Directly Buried Insulated Pipes Market.

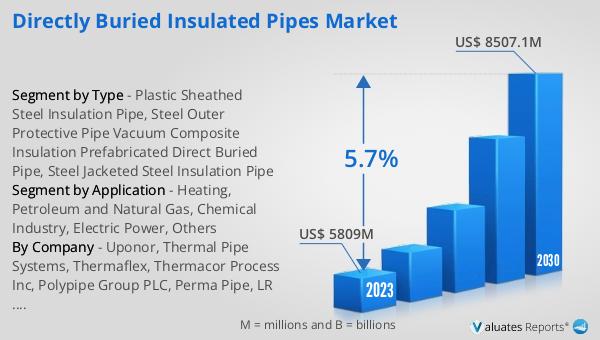

Global Directly Buried Insulated Pipes Market Outlook:

The global market for Directly Buried Insulated Pipes was valued at $6,413 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $9,402 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. This upward trend is indicative of the increasing demand for energy-efficient and sustainable infrastructure solutions across various industries. The market's expansion is driven by several factors, including the growing need for efficient thermal management systems in urban and industrial settings, as well as the rising awareness of the benefits of insulated pipes in reducing energy consumption and operational costs. Additionally, the implementation of stringent environmental regulations and policies aimed at reducing carbon emissions further supports the market's growth. As industries continue to prioritize sustainability and energy efficiency, the demand for directly buried insulated pipes is expected to rise, contributing to the market's robust growth. This positive outlook underscores the importance of innovation and technological advancements in the development of high-performance insulated pipe solutions that meet the evolving needs of diverse industries.

| Report Metric | Details |

| Report Name | Directly Buried Insulated Pipes Market |

| Accounted market size in year | US$ 6413 million |

| Forecasted market size in 2031 | US$ 9402 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Uponor, Thermal Pipe Systems, Thermaflex, Thermacor Process Inc, Polypipe Group PLC, Perma Pipe, LR Marine A/S, Logstor, Isoplus, Insul-Tek Piping Systems Inc, Georg Fischer AG, Brugg Group AG, World Iron & Steel Co.,Ltd, Union Victory (HK) Industry, Guangzhou Mayer Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |