What is Global Incremental Heavy Duty Encoders Market?

The Global Incremental Heavy Duty Encoders Market is a specialized segment within the broader encoder market, focusing on devices designed to withstand harsh environments and demanding applications. These encoders are essential components in various industrial applications, providing precise feedback on position, speed, and direction of mechanical systems. They are particularly valued in industries where reliability and durability are critical, such as manufacturing, automation, and heavy machinery. Incremental encoders work by generating a series of pulses as a disk rotates, which are then counted to determine position or speed. The "heavy duty" aspect refers to their robust construction, which allows them to operate effectively in extreme conditions, including high temperatures, moisture, dust, and vibration. This market is driven by the increasing demand for automation and precision in industrial processes, as well as the need for equipment that can operate reliably in challenging environments. As industries continue to evolve and adopt more sophisticated technologies, the demand for heavy duty encoders is expected to grow, making this a dynamic and important market segment.

Optical Incremental Encoders, Magnetic Incremental Encoders, Inductive Incremental Encoders, Others in the Global Incremental Heavy Duty Encoders Market:

Optical Incremental Encoders are a key component of the Global Incremental Heavy Duty Encoders Market. These encoders use a light source, typically an LED, and a photodetector to read the position of a rotating disk with a pattern of opaque and transparent sections. As the disk rotates, the light is interrupted, creating a series of pulses that are counted to determine position or speed. Optical encoders are known for their high resolution and accuracy, making them ideal for applications requiring precise control. However, they can be sensitive to dust and other contaminants, which can affect performance. Magnetic Incremental Encoders, on the other hand, use magnetic fields to determine position. They consist of a rotating magnet and a stationary sensor that detects changes in the magnetic field as the magnet rotates. These encoders are more robust than optical encoders and can operate in environments with dust, dirt, and moisture. They are often used in applications where durability is more important than ultra-high precision. Inductive Incremental Encoders use electromagnetic induction to generate pulses. They are highly resistant to environmental factors such as dust, moisture, and temperature variations, making them suitable for harsh industrial environments. These encoders are less common than optical and magnetic types but are valued for their robustness and reliability. Other types of incremental encoders in the market include capacitive encoders, which use changes in capacitance to detect position, and hybrid encoders that combine different technologies to achieve specific performance characteristics. Each type of encoder has its own advantages and disadvantages, and the choice of encoder depends on the specific requirements of the application, such as the level of precision needed, the environmental conditions, and the cost constraints. The diversity of encoder types in the Global Incremental Heavy Duty Encoders Market reflects the wide range of applications and industries that rely on these devices for accurate and reliable position and speed feedback.

Steel Industrial, Paper Industrial, Elevator, Oil and Gas, Others in the Global Incremental Heavy Duty Encoders Market:

The Global Incremental Heavy Duty Encoders Market finds extensive usage across various industries, each with its own unique requirements and challenges. In the steel industry, these encoders are crucial for controlling the position and speed of rolling mills, cranes, and other heavy machinery. The harsh environment of steel production, with high temperatures and heavy dust, demands encoders that can withstand such conditions while providing accurate feedback. In the paper industry, incremental heavy duty encoders are used in paper machines and converting equipment to ensure precise control of speed and position. The need for high reliability and accuracy in paper production processes makes these encoders indispensable. Elevators also rely on incremental heavy duty encoders for smooth and safe operation. These encoders provide feedback on the position and speed of the elevator car, ensuring that it stops accurately at each floor and operates efficiently. In the oil and gas industry, encoders are used in drilling rigs, pumps, and other equipment to provide precise control and monitoring. The challenging environments of oil and gas exploration and production, with extreme temperatures and corrosive conditions, require encoders that are robust and reliable. Other industries that use incremental heavy duty encoders include mining, automotive, and aerospace, where they are used in a variety of applications to provide accurate and reliable feedback on position and speed. The versatility and robustness of these encoders make them suitable for a wide range of applications, and their importance in ensuring the efficient and safe operation of industrial processes cannot be overstated.

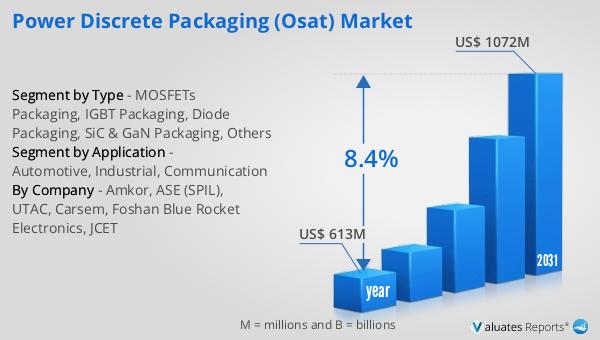

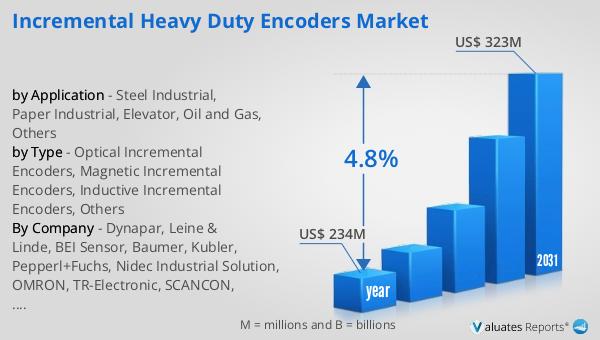

Global Incremental Heavy Duty Encoders Market Outlook:

The global market for Incremental Heavy Duty Encoders was valued at $234 million in 2024, with projections indicating it will grow to a revised size of $323 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.8% over the forecast period. This steady growth can be attributed to the increasing demand for automation and precision in various industrial sectors. As industries continue to evolve and adopt more sophisticated technologies, the need for reliable and accurate feedback systems becomes more critical. Incremental heavy duty encoders, with their robust construction and ability to operate in harsh environments, are well-suited to meet these demands. The market's expansion is also driven by the growing emphasis on improving operational efficiency and reducing downtime in industrial processes. As companies strive to enhance productivity and competitiveness, the adoption of advanced technologies like incremental heavy duty encoders is expected to increase. This market outlook highlights the importance of these encoders in modern industrial applications and underscores their role in driving innovation and efficiency across various sectors.

| Report Metric | Details |

| Report Name | Incremental Heavy Duty Encoders Market |

| Accounted market size in year | US$ 234 million |

| Forecasted market size in 2031 | US$ 323 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dynapar, Leine & Linde, BEI Sensor, Baumer, Kubler, Pepperl+Fuchs, Nidec Industrial Solution, OMRON, TR-Electronic, SCANCON, Hohner Automaticos, Encoder Products Company, Yuheng Optics, Lika Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |