What is Global 28nm Wafer Foundry Market?

The Global 28nm Wafer Foundry Market is a significant segment within the semiconductor industry, focusing on the production of 28-nanometer (nm) wafers. These wafers are crucial components in the manufacturing of integrated circuits, which are used in a wide range of electronic devices. The 28nm technology node represents a balance between performance and cost, making it a popular choice for various applications. This market is driven by the increasing demand for high-performance and energy-efficient electronic devices. Foundries specializing in 28nm technology provide essential services to semiconductor companies that design chips but do not have the facilities to manufacture them. The market's growth is fueled by advancements in technology, the proliferation of smart devices, and the need for more powerful computing solutions. As industries continue to innovate, the demand for 28nm wafers is expected to rise, supporting the development of next-generation electronic products. The market's expansion is also influenced by the competitive landscape, with key players investing in research and development to enhance their production capabilities and maintain a competitive edge. Overall, the Global 28nm Wafer Foundry Market plays a pivotal role in the semiconductor supply chain, enabling the production of advanced electronic components.

8 Inch Wafer, 12 Inch Wafer in the Global 28nm Wafer Foundry Market:

In the context of the Global 28nm Wafer Foundry Market, 8-inch and 12-inch wafers are two primary sizes used in semiconductor manufacturing. An 8-inch wafer, also known as a 200mm wafer, is a silicon disc used as a substrate for fabricating integrated circuits. These wafers are widely used in the production of various semiconductor devices, including microcontrollers, sensors, and analog devices. The 8-inch wafer foundries are typically employed for mature technology nodes, where the demand for cost-effective production is high. On the other hand, a 12-inch wafer, or 300mm wafer, is larger and allows for more chips to be produced per wafer, leading to economies of scale. This size is preferred for advanced technology nodes, such as the 28nm process, due to its efficiency in producing high-performance and high-density chips. The transition from 8-inch to 12-inch wafers in the 28nm foundry market is driven by the need for increased production capacity and reduced manufacturing costs. The larger wafer size enables foundries to produce more chips with fewer resources, making it a cost-effective solution for meeting the growing demand for semiconductor devices. Additionally, the use of 12-inch wafers in the 28nm process allows for the integration of more complex and powerful circuits, supporting the development of cutting-edge technologies. As the semiconductor industry continues to evolve, the adoption of 12-inch wafers in the 28nm foundry market is expected to increase, driven by the need for higher performance and efficiency in electronic devices. The choice between 8-inch and 12-inch wafers in the 28nm foundry market depends on various factors, including production volume, cost considerations, and technological requirements. While 8-inch wafers remain relevant for certain applications, the shift towards 12-inch wafers is evident in the pursuit of advanced semiconductor manufacturing. This transition is supported by advancements in wafer fabrication technology, which enable foundries to produce larger wafers with higher yields and lower defect rates. The use of 12-inch wafers in the 28nm process also aligns with the industry's focus on sustainability, as it reduces material waste and energy consumption. Overall, the Global 28nm Wafer Foundry Market is characterized by the coexistence of 8-inch and 12-inch wafers, each serving specific needs within the semiconductor industry. As technology continues to advance, the demand for larger wafers in the 28nm process is expected to grow, driven by the need for more efficient and cost-effective semiconductor manufacturing solutions.

Smartphone, Computer, IoT, Automotive Electronics, Industrial Control, Others in the Global 28nm Wafer Foundry Market:

The Global 28nm Wafer Foundry Market plays a crucial role in various sectors, including smartphones, computers, the Internet of Things (IoT), automotive electronics, industrial control, and others. In the smartphone industry, 28nm wafers are used to manufacture processors and other critical components that power modern mobile devices. The 28nm technology node offers a balance between performance and power efficiency, making it ideal for smartphones that require high processing power while maintaining long battery life. As smartphones continue to evolve with advanced features and capabilities, the demand for 28nm wafers in this sector is expected to grow. In the computer industry, 28nm wafers are used to produce processors, graphics cards, and other essential components that drive computing performance. The 28nm process allows for the integration of more transistors on a single chip, resulting in faster and more efficient computing solutions. This technology is particularly important for high-performance computing applications, where speed and efficiency are critical. The IoT sector also benefits from the Global 28nm Wafer Foundry Market, as 28nm wafers are used to manufacture sensors, microcontrollers, and other components that enable connectivity and data processing in IoT devices. The 28nm technology node provides the necessary performance and power efficiency required for IoT applications, supporting the development of smart and connected devices. In the automotive electronics industry, 28nm wafers are used to produce chips that power various electronic systems in vehicles, including infotainment systems, advanced driver-assistance systems (ADAS), and engine control units (ECUs). The 28nm process offers the performance and reliability needed for automotive applications, where safety and efficiency are paramount. The industrial control sector also relies on the Global 28nm Wafer Foundry Market for the production of components used in automation and control systems. The 28nm technology node provides the processing power and efficiency required for industrial applications, supporting the development of advanced control systems and machinery. Overall, the Global 28nm Wafer Foundry Market is integral to the advancement of various industries, providing the necessary technology to support innovation and growth. As these sectors continue to evolve, the demand for 28nm wafers is expected to increase, driven by the need for high-performance and energy-efficient solutions.

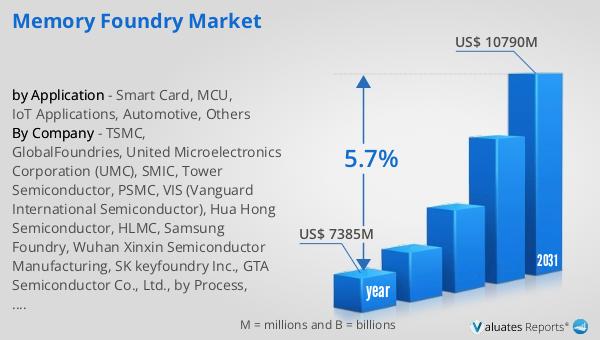

Global 28nm Wafer Foundry Market Outlook:

In 2024, the global market for 28nm Wafer Foundry was valued at approximately $10.26 billion. This market is anticipated to experience significant growth, reaching an estimated size of $27.27 billion by 2031. This expansion represents a compound annual growth rate (CAGR) of 15.2% over the forecast period. The robust growth of this market can be attributed to several factors, including the increasing demand for advanced semiconductor devices across various industries. As technology continues to advance, the need for high-performance and energy-efficient electronic components is driving the demand for 28nm wafers. The 28nm technology node offers a balance between performance and cost, making it an attractive choice for semiconductor manufacturers. Additionally, the proliferation of smart devices, the rise of the Internet of Things (IoT), and the growing demand for automotive electronics are contributing to the market's expansion. The competitive landscape of the Global 28nm Wafer Foundry Market is characterized by key players investing in research and development to enhance their production capabilities and maintain a competitive edge. As the market continues to grow, companies are focusing on innovation and efficiency to meet the increasing demand for 28nm wafers. Overall, the Global 28nm Wafer Foundry Market is poised for significant growth, driven by technological advancements and the increasing demand for high-performance semiconductor devices.

| Report Metric | Details |

| Report Name | 28nm Wafer Foundry Market |

| Accounted market size in year | US$ 10260 million |

| Forecasted market size in 2031 | US$ 27270 million |

| CAGR | 15.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | TSMC, Samsung, GlobalFoundries, SMIC, UMC, Shanghai Huahong, PSMC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |