What is Global Wafer IR Inspection Equipment Market?

The Global Wafer IR Inspection Equipment Market is a specialized segment within the semiconductor industry that focuses on the use of infrared (IR) technology to inspect wafers. Wafers are thin slices of semiconductor material, such as silicon, used in the fabrication of integrated circuits and other microdevices. The IR inspection equipment is crucial for identifying defects and ensuring the quality and reliability of these wafers before they are processed further. This market is driven by the increasing demand for high-quality semiconductors in various applications, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more precise and efficient inspection methods grows, making IR inspection equipment an essential tool for manufacturers. The market is characterized by continuous innovation, with companies investing in research and development to enhance the capabilities of their inspection systems. This includes improving the sensitivity and accuracy of defect detection, as well as increasing the speed and automation of the inspection process. Overall, the Global Wafer IR Inspection Equipment Market plays a vital role in the semiconductor manufacturing process, ensuring that only the highest quality wafers are used in the production of electronic devices.

Fully-automatic, Semi-automatic in the Global Wafer IR Inspection Equipment Market:

In the Global Wafer IR Inspection Equipment Market, the equipment can be broadly categorized into fully-automatic and semi-automatic systems. Fully-automatic wafer IR inspection equipment is designed to operate with minimal human intervention, offering high throughput and precision. These systems are equipped with advanced software and sensors that allow them to detect defects on wafers quickly and accurately. The automation in these systems reduces the likelihood of human error, ensuring consistent quality control. They are particularly beneficial in high-volume manufacturing environments where speed and efficiency are critical. The fully-automatic systems are often integrated into larger production lines, allowing for seamless operation and data integration. On the other hand, semi-automatic wafer IR inspection equipment requires some level of human involvement. These systems are typically used in smaller production facilities or for specialized applications where flexibility and adaptability are more important than speed. Operators may need to manually load and unload wafers or make adjustments to the inspection parameters. While they may not offer the same level of throughput as fully-automatic systems, semi-automatic equipment provides manufacturers with greater control over the inspection process. This can be advantageous in situations where custom inspection criteria are needed or when dealing with complex wafer designs. Both types of equipment play a crucial role in the semiconductor manufacturing process, ensuring that wafers meet the necessary quality standards before they are used in the production of electronic devices. The choice between fully-automatic and semi-automatic systems depends on various factors, including the size of the manufacturing operation, the specific requirements of the inspection process, and the available budget. As the demand for high-quality semiconductors continues to grow, manufacturers are increasingly investing in advanced wafer IR inspection equipment to maintain their competitive edge. This trend is expected to drive further innovation and development in the market, with companies focusing on enhancing the capabilities of both fully-automatic and semi-automatic systems.

200mm Wafer, 300mm Wafer, Others in the Global Wafer IR Inspection Equipment Market:

The Global Wafer IR Inspection Equipment Market finds its application in various wafer sizes, including 200mm, 300mm, and others. Each wafer size presents unique challenges and opportunities for inspection equipment manufacturers. The 200mm wafer, once the industry standard, is still widely used in the production of certain semiconductor devices. These wafers are typically used in mature technology nodes where the demand for high precision and advanced inspection capabilities is not as critical as in newer nodes. However, the need for reliable inspection equipment remains, as defects in 200mm wafers can still impact the performance and yield of the final product. The IR inspection equipment used for 200mm wafers is often designed to balance cost and performance, providing manufacturers with an efficient solution for quality control. In contrast, the 300mm wafer has become the dominant size in the semiconductor industry, particularly for advanced technology nodes. The larger size of these wafers allows for more chips to be produced per wafer, increasing the efficiency of the manufacturing process. However, this also means that any defects present on the wafer can have a more significant impact on yield and profitability. As a result, the demand for high-performance IR inspection equipment is particularly strong in this segment. Manufacturers of 300mm wafers require inspection systems that offer high sensitivity and accuracy, as well as the ability to handle the increased throughput associated with larger wafers. This has led to the development of advanced inspection technologies that can quickly and accurately identify defects, ensuring that only the highest quality wafers are used in production. In addition to 200mm and 300mm wafers, the Global Wafer IR Inspection Equipment Market also serves other wafer sizes, including those used in specialized applications such as MEMS (Micro-Electro-Mechanical Systems) and power devices. These applications often require customized inspection solutions that can accommodate unique wafer sizes and materials. The flexibility and adaptability of IR inspection equipment make it well-suited for these applications, providing manufacturers with the tools they need to ensure the quality and reliability of their products. Overall, the Global Wafer IR Inspection Equipment Market plays a critical role in the semiconductor industry, providing manufacturers with the tools they need to maintain high standards of quality and reliability across a range of wafer sizes and applications.

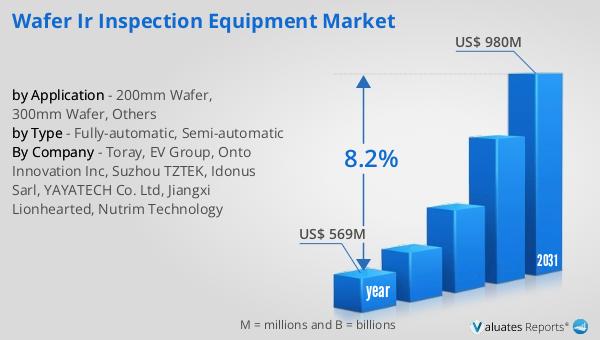

Global Wafer IR Inspection Equipment Market Outlook:

The outlook for the Global Wafer IR Inspection Equipment Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $569 million, and it is anticipated to expand significantly, reaching an estimated size of $980 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.2% over the forecast period. This upward trend reflects the increasing demand for high-quality semiconductor devices across various industries, including consumer electronics, automotive, and telecommunications. As technology continues to advance, the need for precise and efficient inspection methods becomes more critical, driving the demand for advanced IR inspection equipment. The market's growth is also supported by ongoing innovations in inspection technology, with companies investing in research and development to enhance the capabilities of their systems. This includes improving the sensitivity and accuracy of defect detection, as well as increasing the speed and automation of the inspection process. As a result, manufacturers are better equipped to meet the stringent quality standards required in today's competitive semiconductor market. The projected growth of the Global Wafer IR Inspection Equipment Market underscores the importance of these systems in ensuring the quality and reliability of semiconductor devices, ultimately supporting the continued advancement of technology across various sectors.

| Report Metric | Details |

| Report Name | Wafer IR Inspection Equipment Market |

| Accounted market size in year | US$ 569 million |

| Forecasted market size in 2031 | US$ 980 million |

| CAGR | 8.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Toray, EV Group, Onto Innovation Inc, Suzhou TZTEK, Idonus Sarl, YAYATECH Co. Ltd, Jiangxi Lionhearted, Nutrim Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |