What is Global FBG Fiber Optic Strain Sensor Market?

The Global FBG Fiber Optic Strain Sensor Market is a specialized segment within the broader fiber optic sensor industry, focusing on the use of Fiber Bragg Grating (FBG) technology to measure strain. These sensors are highly valued for their precision, reliability, and ability to function in harsh environments. They work by detecting changes in the wavelength of light reflected from a fiber optic cable, which corresponds to the amount of strain experienced by the sensor. This technology is particularly useful in applications where traditional electronic sensors might fail due to electromagnetic interference or extreme conditions. The market for these sensors is driven by their increasing adoption in various industries such as aerospace, civil engineering, and energy, where monitoring structural health and performance is critical. As industries continue to demand more accurate and reliable sensing solutions, the Global FBG Fiber Optic Strain Sensor Market is expected to grow, offering advanced solutions for complex measurement challenges. The sensors' ability to provide real-time data and their long-term stability make them an attractive choice for industries looking to enhance safety and efficiency. With ongoing advancements in fiber optic technology, the market is poised for significant developments in the coming years.

Resolution 0.1 με, Resolution 0.5 με, Resolution 1 με in the Global FBG Fiber Optic Strain Sensor Market:

In the Global FBG Fiber Optic Strain Sensor Market, resolution is a critical factor that determines the sensor's ability to detect minute changes in strain. Resolution is typically measured in microstrain (με), with lower values indicating higher sensitivity. A resolution of 0.1 με represents the highest sensitivity available in the market, allowing for the detection of extremely small changes in strain. This level of precision is essential in applications where even the slightest deformation can have significant consequences, such as in aerospace or high-precision engineering projects. Sensors with a resolution of 0.1 με are often used in environments where safety and accuracy are paramount, providing detailed insights into structural integrity and performance. On the other hand, a resolution of 0.5 με offers a balance between sensitivity and cost, making it suitable for a wide range of applications where moderate precision is sufficient. These sensors are commonly used in civil engineering projects, such as monitoring bridges and buildings, where they provide valuable data on structural health without the need for the highest level of sensitivity. Finally, a resolution of 1 με is typically used in applications where large-scale strain measurements are required, and the need for ultra-high precision is less critical. These sensors are often employed in industries such as energy, where they monitor pipelines and other infrastructure for signs of stress and potential failure. Despite their lower sensitivity, sensors with a resolution of 1 με still offer significant advantages over traditional strain measurement methods, providing reliable data in challenging environments. The choice of resolution depends on the specific requirements of the application, with higher resolutions offering greater precision at a higher cost. As the Global FBG Fiber Optic Strain Sensor Market continues to evolve, advancements in technology are expected to enhance the performance and affordability of these sensors, making them accessible to a broader range of industries and applications.

Architecture, Energy, Aerospace, Others in the Global FBG Fiber Optic Strain Sensor Market:

The Global FBG Fiber Optic Strain Sensor Market finds extensive usage across various sectors, each benefiting from the unique advantages offered by FBG technology. In architecture, these sensors play a crucial role in monitoring the structural health of buildings and infrastructure. They provide real-time data on strain and deformation, allowing engineers to assess the integrity of structures and make informed decisions about maintenance and repairs. This is particularly important in regions prone to natural disasters, where early detection of structural issues can prevent catastrophic failures. In the energy sector, FBG fiber optic strain sensors are used to monitor pipelines, wind turbines, and other critical infrastructure. They help detect signs of stress and potential failure, enabling operators to address issues before they escalate into costly and dangerous problems. The sensors' ability to function in harsh environments makes them ideal for use in remote and challenging locations, where traditional sensors might fail. In aerospace, FBG sensors are employed to monitor the structural health of aircraft and spacecraft. They provide valuable data on the performance of critical components, helping to ensure safety and reliability. The sensors' lightweight and compact design make them suitable for use in the demanding conditions of aerospace applications, where weight and space are at a premium. Beyond these sectors, FBG fiber optic strain sensors are also used in a variety of other applications, including automotive, marine, and industrial monitoring. Their versatility and reliability make them an attractive choice for industries looking to enhance safety, efficiency, and performance. As the demand for advanced sensing solutions continues to grow, the Global FBG Fiber Optic Strain Sensor Market is expected to expand, offering innovative solutions for a wide range of applications.

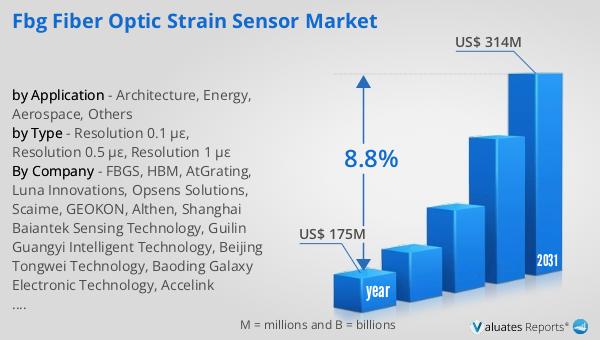

Global FBG Fiber Optic Strain Sensor Market Outlook:

The global market for FBG Fiber Optic Strain Sensors was valued at $175 million in 2024 and is anticipated to grow significantly, reaching an estimated $314 million by 2031. This growth represents a compound annual growth rate (CAGR) of 8.8% over the forecast period. This upward trajectory is driven by the increasing demand for precise and reliable strain measurement solutions across various industries. As sectors such as aerospace, civil engineering, and energy continue to prioritize safety and efficiency, the need for advanced sensing technologies like FBG fiber optic strain sensors is expected to rise. These sensors offer numerous advantages over traditional measurement methods, including immunity to electromagnetic interference, high sensitivity, and the ability to operate in extreme conditions. As a result, they are becoming an integral part of modern monitoring systems, providing critical data that helps industries optimize performance and prevent failures. The projected growth of the market reflects the ongoing advancements in fiber optic technology and the expanding range of applications for FBG sensors. As industries continue to adopt these innovative solutions, the Global FBG Fiber Optic Strain Sensor Market is poised for significant development, offering new opportunities for businesses and consumers alike.

| Report Metric | Details |

| Report Name | FBG Fiber Optic Strain Sensor Market |

| Accounted market size in year | US$ 175 million |

| Forecasted market size in 2031 | US$ 314 million |

| CAGR | 8.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | FBGS, HBM, AtGrating, Luna Innovations, Opsens Solutions, Scaime, GEOKON, Althen, Shanghai Baiantek Sensing Technology, Guilin Guangyi Intelligent Technology, Beijing Tongwei Technology, Baoding Galaxy Electronic Technology, Accelink Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |