What is Global Resistance Welding Machine Sales Market?

The Global Resistance Welding Machine Sales Market refers to the worldwide industry focused on the production, distribution, and sale of resistance welding machines. These machines are essential in various manufacturing processes, as they use the principle of resistance to generate heat and join metal parts together. The market encompasses a wide range of machines, from small, portable units used in workshops to large, automated systems employed in industrial manufacturing. The demand for resistance welding machines is driven by their efficiency, precision, and ability to produce strong, durable welds. Industries such as automotive, aerospace, and electronics heavily rely on these machines for assembling components. The market is characterized by technological advancements, with manufacturers continuously innovating to improve machine performance, energy efficiency, and ease of use. As global manufacturing activities expand, the resistance welding machine market is poised for growth, catering to diverse industrial needs and contributing to the advancement of manufacturing technologies worldwide.

in the Global Resistance Welding Machine Sales Market:

The Global Resistance Welding Machine Sales Market offers a variety of machine types tailored to meet the diverse needs of customers across different industries. One of the most common types is the spot welding machine, which is widely used in the automotive industry for joining sheet metal parts. Spot welding machines are favored for their speed and efficiency, making them ideal for high-volume production lines. Another popular type is the seam welding machine, which is used to create continuous welds along the seams of metal sheets. This type is particularly useful in the production of fuel tanks, radiators, and other cylindrical or rectangular containers. Projection welding machines are another variant, designed to weld multiple points simultaneously. They are often used in the manufacturing of nuts, bolts, and other fasteners, where multiple welds are required at once. Flash welding machines are employed for joining large sections of metal, such as in the construction of railway tracks and pipelines. These machines use a high current to create a flash of heat, melting the metal surfaces before they are pressed together. Upset welding machines, on the other hand, are used for joining rods, wires, and tubes. They work by applying pressure and heat to the ends of the components, causing them to upset and form a strong bond. Each type of resistance welding machine is designed to address specific welding challenges, offering solutions that enhance productivity and product quality. Customers choose machines based on factors such as the type of materials they work with, the thickness of the materials, and the desired speed and precision of the welding process. As technology advances, manufacturers are developing more sophisticated machines with features like automated controls, real-time monitoring, and energy-efficient designs. These innovations are helping customers achieve higher levels of efficiency and precision in their welding operations. Additionally, the integration of digital technologies and smart systems is enabling better control and customization of the welding process, allowing users to optimize their operations for specific applications. The global market for resistance welding machines is thus characterized by a wide range of options, catering to the varied needs of industries and contributing to the advancement of manufacturing capabilities.

in the Global Resistance Welding Machine Sales Market:

Resistance welding machines find applications across a multitude of industries, each leveraging the technology to enhance their manufacturing processes. In the automotive industry, resistance welding is a cornerstone technology used extensively in the assembly of car bodies. Spot welding machines, in particular, are employed to join sheet metal parts, ensuring the structural integrity and safety of vehicles. The aerospace industry also relies on resistance welding for the fabrication of aircraft components, where precision and reliability are paramount. Seam welding machines are often used in the production of fuel tanks and other critical components that require leak-proof joints. In the electronics industry, resistance welding machines are used to assemble small, delicate components such as battery packs and circuit boards. The precision and control offered by these machines make them ideal for applications where accuracy is crucial. The construction industry utilizes resistance welding for the fabrication of steel structures, reinforcing bars, and other metal components. Flash welding machines, for example, are used to join large sections of metal, such as in the construction of bridges and pipelines. The versatility of resistance welding machines also extends to the manufacturing of household appliances, where they are used to assemble components like washing machine drums and refrigerator panels. The ability to produce strong, durable welds quickly and efficiently makes resistance welding an attractive option for manufacturers seeking to optimize their production processes. As industries continue to evolve and demand higher levels of efficiency and precision, the applications of resistance welding machines are expected to expand further. The integration of advanced technologies, such as automation and real-time monitoring, is enhancing the capabilities of these machines, enabling manufacturers to achieve greater control and customization in their welding operations. This adaptability and versatility make resistance welding machines an indispensable tool in modern manufacturing, driving innovation and progress across various sectors.

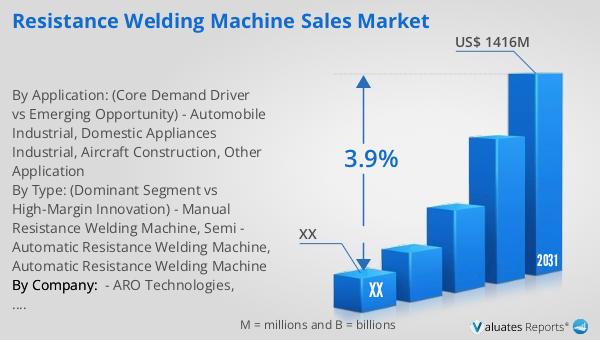

Global Resistance Welding Machine Sales Market Outlook:

The global market for resistance welding machines is poised for significant growth in the coming years. In 2024, the market size was valued at approximately US$ 1,088 million. By 2031, it is projected to reach an adjusted size of US$ 1,416 million, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2025 to 2031. This growth is indicative of the increasing demand for resistance welding machines across various industries, driven by the need for efficient, reliable, and high-quality welding solutions. The market is characterized by a competitive landscape, with the top three manufacturers holding a combined market share of over 20%. These leading companies are at the forefront of innovation, continuously developing new technologies and features to enhance the performance and capabilities of their machines. As the market expands, manufacturers are focusing on improving energy efficiency, automation, and digital integration to meet the evolving needs of their customers. The growth of the resistance welding machine market is also supported by the rising adoption of advanced manufacturing technologies, which are enabling industries to achieve higher levels of productivity and precision. As global manufacturing activities continue to increase, the demand for resistance welding machines is expected to rise, driving further growth and development in the market.

| Report Metric | Details |

| Report Name | Resistance Welding Machine Sales Market |

| Forecasted market size in 2031 | US$ 1416 million |

| CAGR | 3.9% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | ARO Technologies, Fronius International, NIMAK, Nippon Avionics, Daihen Corporation, T. J. Snow, Panasonic Welding Systems, CenterLine, TECNA, Taylor-Winfield, Heron, CEA, Guangzhou LN, Shenzhen Juntengfa, Guangzhou Zongbang, PW Resistance Welding Products, Chengdu Zhengyang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |