What is Global Palletizing Machine Sales Market?

The Global Palletizing Machine Sales Market refers to the worldwide industry involved in the production, distribution, and sale of palletizing machines. These machines are essential in various industries for automating the process of stacking products onto pallets, which are then used for storage or transportation. The market encompasses a wide range of machines, from simple manual systems to highly advanced robotic solutions, catering to different needs and scales of operation. The demand for palletizing machines is driven by the need for efficiency, speed, and accuracy in handling goods, especially in sectors like food and beverage, pharmaceuticals, and manufacturing. As businesses strive to optimize their supply chains and reduce labor costs, the adoption of these machines is on the rise. The market is characterized by technological advancements, with manufacturers continuously innovating to offer more flexible, reliable, and cost-effective solutions. Additionally, the global nature of trade and the increasing complexity of logistics operations further fuel the demand for palletizing machines, making this market a critical component of modern industrial operations.

in the Global Palletizing Machine Sales Market:

In the Global Palletizing Machine Sales Market, various types of machines are utilized by customers based on their specific needs and operational requirements. One of the most common types is the conventional palletizer, which is known for its reliability and simplicity. These machines are typically used in industries where high-speed operations are crucial, such as in the beverage industry, where bottles or cans need to be stacked quickly and efficiently. Conventional palletizers are often preferred for their ability to handle large volumes with minimal downtime. Another popular type is the robotic palletizer, which offers greater flexibility and precision. These machines are equipped with robotic arms that can be programmed to handle different product sizes and shapes, making them ideal for industries with diverse product lines. Robotic palletizers are particularly favored in the food and pharmaceutical industries, where hygiene and precision are paramount. They can easily adapt to changes in product design or packaging, providing a versatile solution for dynamic production environments. Hybrid palletizers, which combine elements of both conventional and robotic systems, are also gaining traction. These machines offer the speed of conventional systems with the flexibility of robotic solutions, making them suitable for a wide range of applications. Additionally, there are specialized palletizers designed for specific tasks, such as bag palletizers, which are used in industries dealing with bulk materials like cement or flour. These machines are designed to handle heavy loads and ensure stable stacking, which is crucial for safe transportation and storage. Another type is the layer palletizer, which arranges products in layers before stacking them onto a pallet. This method is often used for products that require a specific stacking pattern to maintain stability during transit. The choice of palletizing machine depends on several factors, including the type of product, production speed, available space, and budget. Companies often conduct thorough market research to determine the most suitable type of palletizer for their operations, considering both current needs and future scalability. As technology continues to evolve, the range of available palletizing machines is expected to expand, offering even more options for businesses looking to enhance their operational efficiency.

in the Global Palletizing Machine Sales Market:

The Global Palletizing Machine Sales Market serves a wide array of applications across different industries, each with its unique requirements and challenges. In the food and beverage industry, palletizing machines are indispensable for handling products like bottles, cans, and packaged goods. These machines ensure that products are stacked efficiently and securely, minimizing the risk of damage during transportation. The ability to handle high-speed operations is particularly important in this sector, where production lines often run continuously to meet consumer demand. In the pharmaceutical industry, palletizing machines play a crucial role in maintaining the integrity and safety of products. With strict regulations governing the handling and transportation of pharmaceutical goods, these machines are designed to ensure precision and hygiene. They are often used to stack boxes of medicines, medical devices, and other healthcare products, ensuring that they reach their destination in optimal condition. The manufacturing sector also relies heavily on palletizing machines to streamline operations and reduce labor costs. Whether it's automotive parts, electronics, or consumer goods, these machines help in organizing products for efficient storage and distribution. The ability to handle different product sizes and weights is a key consideration in this sector, where versatility and adaptability are highly valued. In the logistics and warehousing industry, palletizing machines are essential for optimizing space and improving the efficiency of loading and unloading operations. By automating the stacking process, these machines help in reducing manual labor and minimizing errors, leading to faster turnaround times and improved productivity. The agricultural sector also benefits from palletizing machines, particularly in the handling of bulk products like grains, seeds, and fertilizers. These machines ensure that products are stacked securely, reducing the risk of spillage and contamination. As the demand for efficient supply chain solutions continues to grow, the applications of palletizing machines are expected to expand, with new industries discovering the benefits of automation in their operations.

Global Palletizing Machine Sales Market Outlook:

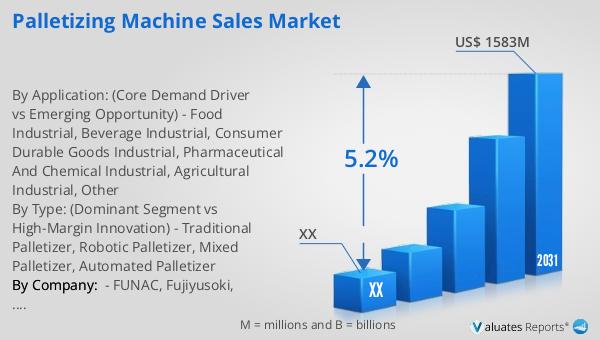

The outlook for the Global Palletizing Machine Market indicates a significant growth trajectory in the coming years. In 2024, the market size was valued at approximately US$ 1,116 million, and it is projected to reach an adjusted size of US$ 1,583 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% during the forecast period from 2025 to 2031. This growth is driven by the increasing demand for automation in various industries, as companies seek to enhance efficiency and reduce operational costs. The market is dominated by the top five manufacturers, who collectively hold a market share exceeding 35%, highlighting the competitive nature of the industry. Geographically, the Asia-Pacific region emerges as the largest market, accounting for about 40% of the global share. This is followed by Europe and North America, both of which have a combined share of over 40%. The robust industrial base and the rapid adoption of automation technologies in these regions contribute to their significant market presence. In terms of product segmentation, the robotic palletizer stands out as the largest segment, with a market share exceeding 45%. This preference for robotic solutions underscores the industry's shift towards more flexible and precise palletizing systems, capable of handling diverse product lines and adapting to changing production needs. As the market continues to evolve, the focus on innovation and technological advancements will be crucial in meeting the growing demand for efficient and reliable palletizing solutions.

| Report Metric | Details |

| Report Name | Palletizing Machine Sales Market |

| Forecasted market size in 2031 | US$ 1583 million |

| CAGR | 5.2% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | FUNAC, Fujiyusoki, ABB, KUKA, YASKAWA, TopTier, Columbia/Okura, A-B-C Packaging, Hartness, Möllers, Kawasaki, C&D Skilled Robotics, NACHI, Gebo Cermex, Arrowhead Systems, Von GAL, Brenton, Chantland-MHS, Buhler, BOSHI, SIASUN, Triowin, LIMA, ESTUN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |