What is Global PA6 Semi Dull Chip Market?

The Global PA6 Semi Dull Chip Market is a significant segment within the broader polymer industry, focusing on the production and distribution of polyamide 6 (PA6) semi-dull chips. These chips are a type of nylon, known for their versatility and durability, making them a popular choice in various industrial applications. PA6 semi-dull chips are characterized by their semi-matte finish, which is achieved through specific manufacturing processes that reduce the glossiness typically associated with nylon products. This unique finish makes them particularly desirable in applications where a less shiny appearance is preferred. The market for these chips is driven by their extensive use in textiles, engineering plastics, and films, among other applications. The demand is further fueled by the growing need for high-performance materials that offer a balance of strength, flexibility, and aesthetic appeal. As industries continue to innovate and seek materials that meet both functional and aesthetic requirements, the PA6 semi-dull chip market is poised for growth. This market's expansion is supported by advancements in production technologies and the increasing adoption of sustainable practices, which are becoming crucial in meeting the evolving demands of global consumers.

Fiber Chip, Engineering Plastic Chip, Pull-film Chip in the Global PA6 Semi Dull Chip Market:

In the Global PA6 Semi Dull Chip Market, fiber chips, engineering plastic chips, and pull-film chips represent distinct categories, each serving unique purposes across various industries. Fiber chips are primarily used in the textile industry, where they are spun into fibers for clothing, upholstery, and other fabric-based applications. These chips are valued for their strength, elasticity, and ability to be dyed in vibrant colors, making them ideal for fashion and home textiles. The semi-dull finish of these chips provides a soft, matte appearance, which is often preferred in clothing and interior design for its understated elegance. Engineering plastic chips, on the other hand, are utilized in the production of high-performance plastics that are used in automotive, electronics, and industrial applications. These chips offer excellent mechanical properties, such as high tensile strength and impact resistance, making them suitable for components that require durability and reliability. The semi-dull finish of these chips also contributes to the aesthetic appeal of the final products, which is important in consumer-facing industries. Pull-film chips are used in the production of films and packaging materials. These chips are processed into thin films that are used for packaging food, electronics, and other consumer goods. The semi-dull finish of these films provides a non-reflective surface, which is beneficial for reducing glare and enhancing the visibility of printed information on packaging. Additionally, the strength and flexibility of pull-film chips make them ideal for creating durable and tear-resistant packaging solutions. The demand for these chips is driven by the need for high-quality, sustainable packaging materials that meet the stringent requirements of modern supply chains. As the Global PA6 Semi Dull Chip Market continues to evolve, the development of innovative applications for fiber, engineering plastic, and pull-film chips will play a crucial role in shaping the future of various industries. The versatility and performance characteristics of these chips make them indispensable in meeting the diverse needs of manufacturers and consumers alike.

Clothing and Civilian, Automotive, Electronics, Food Industry, Chemical Industry, Industrial, Others in the Global PA6 Semi Dull Chip Market:

The Global PA6 Semi Dull Chip Market finds extensive usage across a variety of sectors, including clothing and civilian, automotive, electronics, food industry, chemical industry, industrial, and others. In the clothing and civilian sector, PA6 semi-dull chips are transformed into fibers that are woven into fabrics for garments, home textiles, and other consumer products. The semi-dull finish of these fibers provides a soft, matte appearance that is highly sought after in fashion and interior design. The durability and elasticity of PA6 fibers make them ideal for creating comfortable, long-lasting clothing and textiles that can withstand regular wear and tear. In the automotive industry, PA6 semi-dull chips are used to produce engineering plastics that are essential for manufacturing various components, such as interior panels, under-the-hood parts, and exterior trims. These plastics offer excellent mechanical properties, including high impact resistance and thermal stability, which are crucial for ensuring the safety and performance of vehicles. The semi-dull finish of these components also enhances the aesthetic appeal of automotive interiors and exteriors, contributing to a premium look and feel. In the electronics sector, PA6 semi-dull chips are used to create components that require precision and reliability, such as connectors, housings, and insulators. The chips' excellent electrical insulation properties and resistance to heat and chemicals make them suitable for use in electronic devices and appliances. The semi-dull finish of these components helps reduce glare and improve the overall appearance of electronic products. In the food industry, PA6 semi-dull chips are used to produce packaging materials that protect food products from contamination and spoilage. The strength and flexibility of these materials make them ideal for creating durable, tear-resistant packaging solutions that can withstand the rigors of transportation and storage. The semi-dull finish of the packaging also enhances the visibility of printed information, such as branding and nutritional labels, making it easier for consumers to identify and select products. In the chemical industry, PA6 semi-dull chips are used to manufacture containers and equipment that require resistance to corrosive substances and high temperatures. The chips' excellent chemical resistance and mechanical properties make them suitable for use in harsh environments, where durability and reliability are paramount. In the industrial sector, PA6 semi-dull chips are used to produce components and equipment that require high performance and longevity, such as gears, bearings, and conveyor belts. The chips' strength, wear resistance, and thermal stability make them ideal for use in demanding applications where failure is not an option. The versatility and performance characteristics of PA6 semi-dull chips make them indispensable in meeting the diverse needs of manufacturers and consumers across various industries.

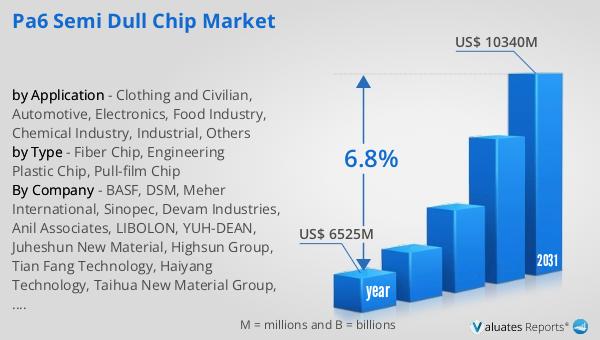

Global PA6 Semi Dull Chip Market Outlook:

The global market for PA6 Semi Dull Chip was valued at $6,525 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $10,340 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. The market's expansion is driven by the increasing demand for high-performance materials across various industries, including textiles, automotive, electronics, and packaging. As industries continue to innovate and seek materials that offer a balance of strength, flexibility, and aesthetic appeal, the PA6 semi-dull chip market is poised for growth. The market's expansion is supported by advancements in production technologies and the increasing adoption of sustainable practices, which are becoming crucial in meeting the evolving demands of global consumers. The versatility and performance characteristics of PA6 semi-dull chips make them indispensable in meeting the diverse needs of manufacturers and consumers alike. As the market continues to evolve, the development of innovative applications for fiber, engineering plastic, and pull-film chips will play a crucial role in shaping the future of various industries. The versatility and performance characteristics of these chips make them indispensable in meeting the diverse needs of manufacturers and consumers alike.

| Report Metric | Details |

| Report Name | PA6 Semi Dull Chip Market |

| Accounted market size in year | US$ 6525 million |

| Forecasted market size in 2031 | US$ 10340 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | BASF, DSM, Meher International, Sinopec, Devam Industries, Anil Associates, LIBOLON, YUH-DEAN, Juheshun New Material, Highsun Group, Tian Fang Technology, Haiyang Technology, Taihua New Material Group, Hiscien Engineering, Eversun Jinjiang, Keyuan Plastic, SFT ENTERPRISE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |