What is Global Natural Gas Dehydration Device Market?

The Global Natural Gas Dehydration Device Market refers to the industry focused on the production and sale of equipment used to remove water vapor from natural gas. This process is crucial because natural gas often contains water vapor that can lead to pipeline corrosion, hydrate formation, and other operational issues if not properly managed. Dehydration devices ensure that the gas meets the required specifications for transportation and use. The market encompasses various technologies and methods, including absorption, adsorption, and condensation, each with its own advantages and applications. The demand for these devices is driven by the increasing global consumption of natural gas, which is seen as a cleaner alternative to other fossil fuels. As countries strive to reduce carbon emissions, the role of natural gas in the energy mix is expected to grow, thereby boosting the need for efficient dehydration solutions. Companies operating in this market are continuously innovating to improve the efficiency and cost-effectiveness of their products, catering to the diverse needs of the energy sector. The market is characterized by a mix of established players and new entrants, all vying to capture a share of this expanding industry.

Absorption, Adsorption, Condensation in the Global Natural Gas Dehydration Device Market:

In the Global Natural Gas Dehydration Device Market, three primary methods are employed to remove water vapor from natural gas: absorption, adsorption, and condensation. Each method has its unique characteristics and applications, making them suitable for different operational requirements. Absorption involves the use of a liquid desiccant, such as glycol, to absorb water vapor from the gas stream. The natural gas is passed through a contactor tower where it comes into contact with the glycol, which absorbs the moisture. This method is widely used due to its efficiency and ability to handle large volumes of gas. The absorbed water is then removed from the glycol in a regeneration process, allowing the glycol to be reused. Adsorption, on the other hand, uses solid desiccants like silica gel or molecular sieves to capture water molecules. The gas is passed through a bed of these desiccants, which trap the water vapor. This method is particularly effective for achieving very low dew points and is often used in applications where extremely dry gas is required. The desiccants can be regenerated by heating or pressure reduction, making the process cyclic. Condensation involves cooling the gas to a temperature where water vapor condenses into liquid form and can be separated from the gas stream. This method is typically used in conjunction with other dehydration techniques to achieve the desired level of dryness. It is particularly useful in situations where the gas is already at a high pressure, as the cooling process can be more easily managed. Each of these methods has its advantages and limitations, and the choice of method depends on factors such as the composition of the gas, the required dew point, and economic considerations. Companies in the market are continually exploring ways to optimize these processes, improve energy efficiency, and reduce operational costs. The integration of advanced technologies and automation is also playing a significant role in enhancing the performance of dehydration devices. As the demand for natural gas continues to rise, the importance of efficient dehydration solutions becomes increasingly critical, driving innovation and growth in the market.

Energy, Chemicals, Others in the Global Natural Gas Dehydration Device Market:

The usage of Global Natural Gas Dehydration Devices spans across various sectors, including energy, chemicals, and others, each with specific requirements and challenges. In the energy sector, these devices are essential for ensuring the safe and efficient transportation of natural gas. Dehydration is a critical step in the processing of natural gas, as it prevents the formation of hydrates and corrosion in pipelines, which can lead to blockages and damage. By removing water vapor, dehydration devices help maintain the integrity of the infrastructure and ensure a steady supply of gas to power plants and other energy facilities. In the chemical industry, natural gas dehydration devices play a vital role in the production of various chemicals and petrochemicals. Many chemical processes require dry gas as a feedstock to prevent unwanted reactions and ensure product quality. Dehydration devices help achieve the necessary gas specifications, enabling the efficient operation of chemical plants. Additionally, the removal of water vapor is crucial in processes such as ammonia production, where moisture can affect the efficiency of catalysts and the overall yield. Beyond energy and chemicals, natural gas dehydration devices find applications in other industries such as manufacturing and transportation. In manufacturing, dry gas is often required for processes that involve high temperatures or pressures, where the presence of moisture can lead to equipment failure or product defects. In the transportation sector, particularly in the case of liquefied natural gas (LNG), dehydration is a critical step in the liquefaction process. Removing water vapor is essential to prevent the formation of ice and hydrates, which can impede the efficient storage and transport of LNG. Overall, the versatility and importance of natural gas dehydration devices across various sectors underscore their significance in the global market. As industries continue to seek cleaner and more efficient energy solutions, the demand for effective dehydration technologies is expected to grow, driving further advancements and innovations in the field.

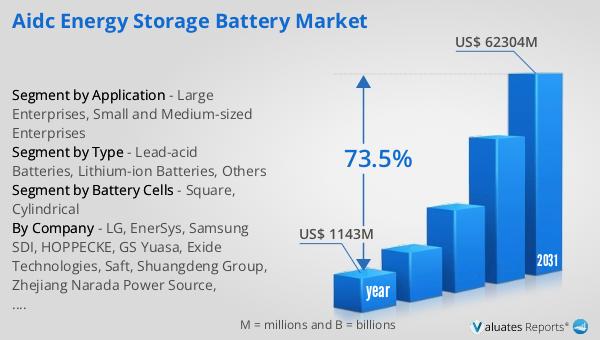

Global Natural Gas Dehydration Device Market Outlook:

The global market for Natural Gas Dehydration Devices was valued at $2,486 million in 2024 and is anticipated to expand to a revised size of $4,124 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.5% over the forecast period. This growth trajectory underscores the increasing importance of natural gas as a key energy source in the global energy mix. As countries worldwide strive to reduce their carbon footprints and transition towards cleaner energy solutions, natural gas is emerging as a preferred alternative due to its lower emissions compared to other fossil fuels. The rising demand for natural gas is driving the need for efficient dehydration solutions to ensure the safe and effective transportation and utilization of this resource. The market's expansion is also fueled by technological advancements and innovations aimed at enhancing the efficiency and cost-effectiveness of dehydration devices. Companies are investing in research and development to develop new materials and processes that can improve the performance of these devices, reduce energy consumption, and lower operational costs. Additionally, the integration of digital technologies and automation is playing a significant role in optimizing the operation of dehydration systems, further contributing to market growth. As the global energy landscape continues to evolve, the role of natural gas dehydration devices is expected to become increasingly critical, supporting the transition towards a more sustainable and efficient energy future.

| Report Metric | Details |

| Report Name | Natural Gas Dehydration Device Market |

| Accounted market size in year | US$ 2486 million |

| Forecasted market size in 2031 | US$ 4124 million |

| CAGR | 7.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schlumberger, Honeywell, Sulzer, CECO Environmental, Kimray, HC Petroleum Equipment, GazSurf, Generon, Baker Hughes, Enerflex, Technip Energies, Toyo Engineering, Hengye Molecular Sieve, Jereh Hengri Natural Gas Engineering, Tongda Machinery Manufacturing, Huawang New Energy, LUDY Petrochemical Equipment, Yiyuan Tongyong Equipment, Fucheng Gas Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |