What is Global Final Shaping Machine Market?

The Global Final Shaping Machine Market is a specialized segment within the broader manufacturing and machinery industry, focusing on machines designed to shape and finish various materials into precise forms. These machines are integral to industries that require high precision and efficiency in shaping components, such as automotive, aerospace, and electronics. The market encompasses a range of machines, including hydraulic and servo-based systems, each offering unique advantages in terms of speed, accuracy, and energy efficiency. The demand for final shaping machines is driven by the need for high-quality, precision-engineered components in various sectors. As industries continue to innovate and require more complex and precise parts, the market for these machines is expected to grow. Additionally, advancements in technology, such as automation and digitalization, are further enhancing the capabilities of these machines, making them more versatile and efficient. The global reach of this market indicates its importance in the manufacturing landscape, providing essential tools for industries worldwide to maintain competitiveness and meet the ever-evolving demands of modern production.

Hydraulic, Servo in the Global Final Shaping Machine Market:

Hydraulic and servo-based systems are two prominent types of machines within the Global Final Shaping Machine Market, each offering distinct benefits and applications. Hydraulic shaping machines are known for their robustness and ability to handle heavy-duty tasks. They operate using hydraulic fluid to power the machine's movements, providing consistent force and precision. This makes them ideal for applications requiring significant force, such as metal forming and heavy material shaping. Hydraulic machines are often favored in industries where durability and reliability are paramount, and they can operate under harsh conditions without compromising performance. On the other hand, servo-based shaping machines utilize servo motors to control their movements, offering superior precision and speed. These machines are highly efficient and can be programmed for complex tasks, making them suitable for industries that require high precision and flexibility, such as electronics and aerospace. Servo-based machines are also more energy-efficient compared to their hydraulic counterparts, as they consume power only when needed, reducing operational costs. The choice between hydraulic and servo-based machines often depends on the specific requirements of the application, such as the material being shaped, the desired precision, and the production volume. Both types of machines play a crucial role in the Global Final Shaping Machine Market, catering to diverse industrial needs and contributing to the overall growth and innovation within the sector. As technology continues to advance, these machines are expected to become even more sophisticated, offering enhanced capabilities and efficiencies to meet the evolving demands of modern manufacturing.

Automotive, Home Appliances, Mechanical Equipment, Robot, Others in the Global Final Shaping Machine Market:

The Global Final Shaping Machine Market finds extensive applications across various industries, including automotive, home appliances, mechanical equipment, robotics, and others. In the automotive sector, these machines are essential for producing precision components such as engine parts, transmission systems, and body panels. The demand for high-quality, durable, and lightweight automotive components drives the need for advanced shaping machines that can deliver consistent and accurate results. In the home appliances industry, final shaping machines are used to manufacture components for products like refrigerators, washing machines, and air conditioners. These machines ensure that parts are produced with the exact specifications required for efficient assembly and operation. In the realm of mechanical equipment, shaping machines are crucial for creating parts that require high precision and strength, such as gears, shafts, and bearings. The robotics industry also relies heavily on final shaping machines to produce components that require intricate designs and precise dimensions. As robots become more sophisticated and capable, the demand for high-precision parts continues to grow, further driving the need for advanced shaping machines. Additionally, other industries, such as electronics and aerospace, utilize these machines to produce components that require exceptional accuracy and quality. The versatility and efficiency of final shaping machines make them indispensable tools in modern manufacturing, enabling industries to meet the increasing demands for high-quality products.

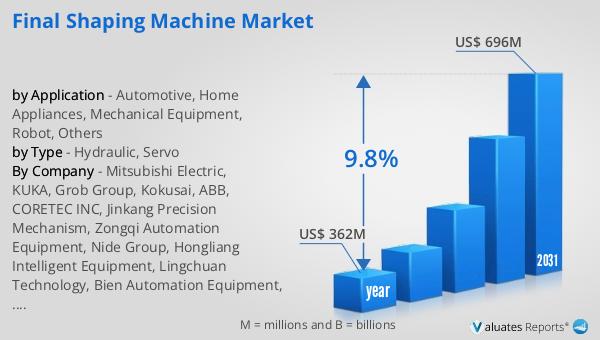

Global Final Shaping Machine Market Outlook:

The global market for Final Shaping Machines was valued at approximately $362 million in 2024, with projections indicating a significant growth trajectory. By 2031, the market is expected to reach an estimated size of $696 million, reflecting a compound annual growth rate (CAGR) of 9.8% over the forecast period. This growth underscores the increasing demand for precision-engineered components across various industries, driven by technological advancements and the need for high-quality manufacturing solutions. The market's expansion is indicative of the critical role that final shaping machines play in modern production processes, providing the necessary tools for industries to maintain competitiveness and meet evolving consumer demands. As industries continue to innovate and require more complex and precise parts, the demand for these machines is expected to grow, further fueling the market's expansion. The projected growth also highlights the importance of continued investment in research and development to enhance the capabilities and efficiencies of these machines, ensuring they can meet the future needs of the manufacturing sector.

| Report Metric | Details |

| Report Name | Final Shaping Machine Market |

| Accounted market size in year | US$ 362 million |

| Forecasted market size in 2031 | US$ 696 million |

| CAGR | 9.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mitsubishi Electric, KUKA, Grob Group, Kokusai, ABB, CORETEC INC, Jinkang Precision Mechanism, Zongqi Automation Equipment, Nide Group, Hongliang Intelligent Equipment, Lingchuan Technology, Bien Automation Equipment, Huan Century Rui Automation Equipment, SMT Intelligent Device Manufacturing, Hongdian Automation, Great Dragon Automation, Suchun Electromechanical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |