What is Global Industrial Coding Equipment Market?

The Global Industrial Coding Equipment Market refers to the industry focused on the production and distribution of machinery and tools used to print codes, labels, and other essential information on products and packaging. This market is crucial for ensuring that products are traceable, compliant with regulations, and easily identifiable throughout the supply chain. Industrial coding equipment is used across various sectors, including food and beverage, pharmaceuticals, automotive, and consumer goods, to print barcodes, expiration dates, batch numbers, and other critical data. The market is driven by the increasing demand for product traceability, the need for efficient supply chain management, and stringent regulatory requirements. As industries continue to expand globally, the demand for reliable and efficient coding solutions grows, making this market an essential component of modern manufacturing and distribution processes. The market is characterized by technological advancements, with companies continuously innovating to provide more efficient, cost-effective, and environmentally friendly coding solutions. The growth of e-commerce and globalization further fuels the demand for industrial coding equipment, as products need to be accurately labeled and tracked across borders. Overall, the Global Industrial Coding Equipment Market plays a vital role in ensuring product safety, quality, and compliance in today's interconnected world.

CIJ, TIJ, TTO, Laser, Others in the Global Industrial Coding Equipment Market:

Continuous Inkjet (CIJ) technology is a widely used method in the Global Industrial Coding Equipment Market, known for its ability to print on virtually any surface at high speeds. CIJ systems work by expelling a continuous stream of ink droplets, which are electrically charged and deflected to form characters on a substrate. This technology is favored for its versatility, as it can print on curved, flat, or irregular surfaces, making it ideal for industries like food and beverage, pharmaceuticals, and automotive. CIJ printers are capable of producing high-quality codes and are often used for printing expiration dates, batch numbers, and barcodes. Thermal Inkjet (TIJ) technology, on the other hand, is known for its precision and high-resolution printing capabilities. TIJ printers use heat to create bubbles in the ink, which then expel droplets onto the substrate. This technology is particularly suited for printing on porous surfaces like paper and cardboard, making it popular in the packaging industry. TIJ printers are compact, easy to maintain, and offer excellent print quality, making them a preferred choice for applications requiring detailed and crisp codes. Thermal Transfer Overprinting (TTO) is another key technology in the industrial coding market, primarily used for printing on flexible packaging materials. TTO printers use a thermal printhead to transfer ink from a ribbon onto the substrate, producing high-resolution images and text. This technology is ideal for printing variable data, such as barcodes and QR codes, on packaging films, labels, and other flexible materials. TTO is favored for its ability to produce durable and smudge-resistant prints, making it suitable for industries like food and pharmaceuticals where packaging integrity is crucial. Laser coding technology is gaining popularity due to its ability to produce permanent, high-quality marks without the need for consumables like ink or ribbons. Laser coders use focused beams of light to etch or engrave codes onto a variety of surfaces, including metals, plastics, and glass. This technology is highly precise and can produce intricate designs, making it ideal for applications requiring tamper-proof and counterfeit-resistant codes. Laser coding is also environmentally friendly, as it eliminates the need for inks and solvents, reducing waste and emissions. Other technologies in the industrial coding market include Dot Peen and Hot Foil Stamping, each offering unique benefits for specific applications. Dot Peen marking uses a stylus to create indented dots on a surface, forming characters and images. This method is durable and can withstand harsh environments, making it suitable for industries like aerospace and automotive. Hot Foil Stamping, on the other hand, uses heat and pressure to transfer metallic or colored foils onto a substrate, creating decorative and eye-catching designs. This technology is often used in the luxury goods and packaging industries to enhance product aesthetics. Overall, the Global Industrial Coding Equipment Market offers a diverse range of technologies, each catering to specific industry needs and applications. As industries continue to evolve, the demand for innovative and efficient coding solutions will drive further advancements in this market.

Food and Beverage, Pharmaceutical and Consumer, Aerospace and Automotive, Others in the Global Industrial Coding Equipment Market:

The Global Industrial Coding Equipment Market plays a crucial role in various industries, providing essential solutions for product identification, traceability, and compliance. In the food and beverage sector, coding equipment is used to print expiration dates, batch numbers, and barcodes on packaging, ensuring product safety and regulatory compliance. This industry relies heavily on coding solutions to maintain supply chain efficiency and prevent product recalls. The pharmaceutical and consumer goods industries also benefit significantly from industrial coding equipment, as it enables the printing of critical information such as dosage instructions, manufacturing dates, and serial numbers on packaging. This ensures that products are safe for consumption and meet regulatory standards. In the aerospace and automotive industries, coding equipment is used to mark components and parts with identification numbers, manufacturing dates, and other essential information. This helps in tracking and managing inventory, ensuring quality control, and facilitating recalls if necessary. The durability and precision of coding solutions are particularly important in these industries, where safety and reliability are paramount. Other sectors, such as electronics, textiles, and logistics, also utilize industrial coding equipment to enhance product traceability and streamline operations. In the electronics industry, coding solutions are used to mark circuit boards and components with identification codes, ensuring proper assembly and quality control. The textile industry uses coding equipment to label garments and fabrics with care instructions and size information, improving inventory management and customer satisfaction. In logistics, coding solutions help in tracking shipments and managing inventory, ensuring timely delivery and efficient supply chain operations. Overall, the Global Industrial Coding Equipment Market provides essential tools for various industries, enabling them to meet regulatory requirements, enhance product safety, and improve operational efficiency. As industries continue to evolve and face new challenges, the demand for innovative and reliable coding solutions will continue to grow, driving further advancements in this market.

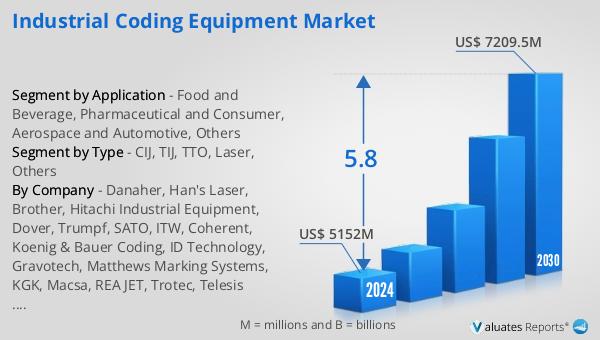

Global Industrial Coding Equipment Market Outlook:

In 2024, the global market for Industrial Coding Equipment was valued at approximately $5,419 million, and it is anticipated to expand to a revised size of around $7,976 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.8% over the forecast period. Among the leading manufacturers in this sector are Danaher, Hans Laser, and Brother, collectively holding about 30% of the market share. Notably, Danaher and Hans Laser each contribute over 10% to the market. Europe stands out as the most significant region for the production of industrial coding equipment, commanding a market share exceeding 25%. When examining the types of coding equipment, laser technology emerges as a dominant force, capturing more than 45% of the market share. In terms of application, the food and beverage industry is a major player, accounting for over 40% of the market share. This data underscores the critical role that industrial coding equipment plays across various sectors, driven by the need for efficient product identification, traceability, and compliance with industry standards. As the market continues to grow, driven by technological advancements and increasing demand from diverse industries, the importance of reliable and innovative coding solutions becomes ever more apparent.

| Report Metric | Details |

| Report Name | Industrial Coding Equipment Market |

| Accounted market size in year | US$ 5419 million |

| Forecasted market size in 2031 | US$ 7976 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Danaher, Han's Laser, Brother, Hitachi Industrial Equipment, Dover, Trumpf, SATO, ITW, Coherent, Koenig & Bauer Coding, ID Technology, Gravotech, Matthews Marking Systems, KGK, Macsa, REA JET, Trotec, Telesis Technologies, Control print, TYKMA Electrox, SUNINE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |