What is Global LNG Insulation Panel Market?

The Global LNG Insulation Panel Market is a specialized segment within the broader insulation industry, focusing on providing thermal insulation solutions for liquefied natural gas (LNG) applications. These panels are crucial for maintaining the extremely low temperatures required to keep natural gas in its liquid state during storage and transportation. The market has been experiencing significant growth due to the increasing demand for LNG as a cleaner energy source compared to traditional fossil fuels. Insulation panels are designed to minimize heat transfer, ensuring that LNG remains at a stable temperature, which is essential for safety and efficiency. The panels are typically made from materials that offer high thermal resistance and durability, such as polyurethane foam, polystyrene, and other advanced composites. As the global energy landscape shifts towards more sustainable options, the demand for LNG and, consequently, LNG insulation panels is expected to rise. This growth is further driven by technological advancements in insulation materials and the expansion of LNG infrastructure worldwide. The market is characterized by a few dominant players who hold significant market shares, and it is heavily influenced by regional consumption patterns, particularly in Asia-Pacific, which is the largest consumer of LNG insulation panels.

Foaming Agent, Laminated Densified Wood in the Global LNG Insulation Panel Market:

Foaming agents and laminated densified wood play pivotal roles in the Global LNG Insulation Panel Market, each contributing to the efficiency and effectiveness of insulation solutions. Foaming agents are chemical substances used to create foam, which is a key component in many insulation materials. In the context of LNG insulation panels, foaming agents help produce lightweight, yet highly effective, insulating foams such as polyurethane and polystyrene. These foams are known for their excellent thermal insulation properties, which are crucial for maintaining the low temperatures required for LNG storage and transportation. The foaming process involves the expansion of the foam material, creating a cellular structure that traps air and reduces heat transfer. This makes foaming agents indispensable in the production of insulation panels that need to withstand extreme temperature variations while maintaining structural integrity. On the other hand, laminated densified wood is an innovative material used in some LNG insulation applications. It is created by compressing and bonding layers of wood veneers under high pressure and temperature, resulting in a dense, durable material with excellent mechanical properties. Laminated densified wood offers several advantages, including high strength-to-weight ratio, dimensional stability, and resistance to moisture and chemicals. These properties make it suitable for use in environments where traditional insulation materials might fail. In the LNG insulation panel market, laminated densified wood can be used as a structural component or as part of a composite insulation system, providing additional support and protection. The combination of foaming agents and laminated densified wood in LNG insulation panels results in products that are not only effective at thermal insulation but also robust and long-lasting. As the demand for LNG continues to grow, the need for advanced insulation materials like these will likely increase, driving further innovation and development in the market. Manufacturers are continually exploring new formulations and production techniques to enhance the performance of foaming agents and laminated densified wood, ensuring that LNG insulation panels meet the stringent requirements of the industry. This ongoing research and development are crucial for maintaining the safety, efficiency, and sustainability of LNG operations worldwide.

LNG Carrier, LNG Receiving Station, Others in the Global LNG Insulation Panel Market:

The usage of Global LNG Insulation Panel Market products extends across various critical areas, including LNG carriers, LNG receiving stations, and other related applications. LNG carriers are specialized ships designed to transport liquefied natural gas across vast distances. These vessels require highly efficient insulation systems to maintain the LNG at cryogenic temperatures, preventing it from evaporating during transit. Insulation panels used in LNG carriers are typically made from advanced materials like polyurethane foam, which offers excellent thermal resistance and durability. The panels are installed in the cargo tanks, where they minimize heat transfer and ensure the LNG remains in its liquid state. This is crucial for the safety and efficiency of LNG transportation, as any significant temperature increase could lead to pressure build-up and potential hazards. In LNG receiving stations, insulation panels play a vital role in the storage and regasification processes. These stations are the final destination for LNG carriers, where the liquefied gas is offloaded and stored in large tanks before being converted back into its gaseous form for distribution. Insulation panels in receiving stations help maintain the low temperatures required for LNG storage, ensuring that the gas remains stable and ready for regasification. The panels are designed to withstand the harsh environmental conditions often found at these facilities, providing reliable performance over extended periods. Beyond LNG carriers and receiving stations, insulation panels are also used in other applications within the LNG supply chain. This includes pipelines, processing plants, and storage facilities, where maintaining low temperatures is essential for operational efficiency and safety. In these contexts, insulation panels help reduce energy consumption by minimizing heat loss, contributing to the overall sustainability of LNG operations. The versatility and effectiveness of LNG insulation panels make them indispensable in the global energy landscape, where the demand for cleaner and more efficient energy sources continues to rise. As the LNG industry expands, the need for advanced insulation solutions will grow, driving further innovation and development in the market.

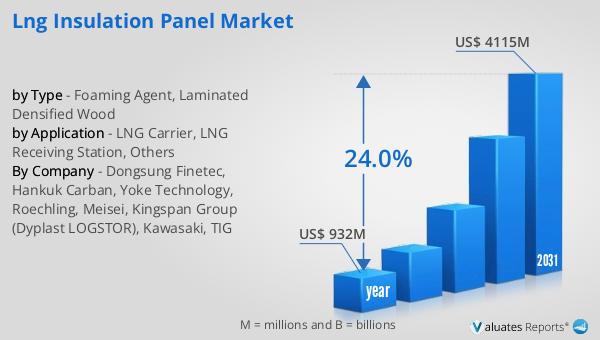

Global LNG Insulation Panel Market Outlook:

The global market for LNG Insulation Panels was valued at approximately $932 million in 2024 and is anticipated to expand to a revised size of $4,115 million by 2031, reflecting a robust compound annual growth rate (CAGR) of 24.0% during the forecast period. The market is dominated by a few key players, with the top five manufacturers—Dongsung Finetec, Hankuk Carbon, Yoke Technology, Roechling, and Meisei—collectively holding about 90% of the market share. Among these, Dongsung Finetec stands out as the largest manufacturer, commanding a market share exceeding 35%. The Asia-Pacific region emerges as the most significant consumer market for LNG insulation panels, accounting for more than 60% of global consumption. This regional dominance is driven by the rapid industrialization and increasing energy demands in countries like China, Japan, and South Korea. In terms of product types, foaming agents represent a substantial portion of the market, with a share of approximately 80%. These agents are crucial for producing the lightweight, high-performance insulation materials required for LNG applications. The strong growth trajectory of the LNG insulation panel market underscores the increasing importance of LNG as a cleaner energy source and the critical role of advanced insulation solutions in supporting its safe and efficient use.

| Report Metric | Details |

| Report Name | LNG Insulation Panel Market |

| Accounted market size in year | US$ 932 million |

| Forecasted market size in 2031 | US$ 4115 million |

| CAGR | 24.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dongsung Finetec, Hankuk Carban, Yoke Technology, Roechling, Meisei, Kingspan Group (Dyplast LOGSTOR), Kawasaki, TIG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |