What is Global Heavy Duty Encoders Sales Market?

The Global Heavy Duty Encoders Sales Market refers to the worldwide industry focused on the production and sale of heavy-duty encoders. These devices are essential components in various industrial applications, providing precise feedback on the position, speed, and direction of mechanical systems. Heavy-duty encoders are designed to withstand harsh environments, including extreme temperatures, moisture, and vibration, making them ideal for use in industries such as manufacturing, automotive, aerospace, and energy. The market encompasses a wide range of encoder types, including rotary and linear encoders, each serving specific needs based on the application requirements. The demand for heavy-duty encoders is driven by the increasing automation in industries, where accurate and reliable motion control is crucial. As industries continue to adopt advanced technologies, the need for robust and durable encoders is expected to grow, contributing to the expansion of the global market. The market is characterized by technological advancements, with manufacturers focusing on developing encoders that offer higher precision, better durability, and enhanced connectivity features. This market is also influenced by regional industrial growth, regulatory standards, and the overall economic climate, which can impact the demand and supply dynamics.

in the Global Heavy Duty Encoders Sales Market:

In the Global Heavy Duty Encoders Sales Market, various types of encoders are utilized by customers based on their specific needs and applications. Rotary encoders are one of the most common types, used to measure the rotational position and speed of a shaft or axle. These encoders are further divided into incremental and absolute encoders. Incremental encoders provide relative position information, which is useful in applications where the position is reset frequently, such as in conveyor systems or robotic arms. Absolute encoders, on the other hand, provide a unique position value, making them suitable for applications where position data must be retained even after power loss, such as in CNC machines or elevators. Linear encoders are another type, used to measure linear displacement. They are often employed in precision measurement applications, such as in coordinate measuring machines or in the semiconductor industry. Optical encoders, which use light to detect position changes, are favored for their high accuracy and resolution, making them ideal for applications requiring precise control, such as in medical devices or aerospace systems. Magnetic encoders, which use magnetic fields to determine position, are preferred in environments where dust, dirt, or moisture might interfere with optical systems. They are commonly used in automotive applications or in outdoor equipment. Capacitive encoders, which use changes in capacitance to detect position, offer a robust solution for environments with high levels of vibration or shock. They are often found in heavy machinery or industrial automation systems. Each type of encoder offers distinct advantages and is chosen based on factors such as environmental conditions, required precision, and cost considerations. The choice of encoder type is critical to ensuring optimal performance and reliability in the intended application. As technology advances, the development of hybrid encoders, which combine features of different types, is becoming more prevalent, offering enhanced functionality and versatility. Customers in the Global Heavy Duty Encoders Sales Market must carefully evaluate their specific needs and application requirements to select the most appropriate encoder type, ensuring efficient and reliable operation in their systems.

in the Global Heavy Duty Encoders Sales Market:

The Global Heavy Duty Encoders Sales Market serves a wide array of applications across various industries, each requiring precise and reliable motion control solutions. In the manufacturing sector, heavy-duty encoders are integral to automation processes, providing accurate feedback for robotic arms, conveyor systems, and CNC machines. These encoders ensure precise positioning and speed control, which are essential for maintaining product quality and operational efficiency. In the automotive industry, encoders are used in assembly lines, where they help control the movement of parts and components, ensuring precise alignment and assembly. They are also used in testing and quality control processes, where accurate measurement of rotational speed and position is crucial. The aerospace industry relies on heavy-duty encoders for applications such as flight control systems, where they provide critical feedback on the position and movement of control surfaces. In the energy sector, encoders are used in wind turbines and solar tracking systems, where they help optimize the positioning of blades and panels to maximize energy capture. The medical industry uses encoders in imaging equipment and surgical robots, where precision and reliability are paramount. In the logistics and material handling industry, encoders are used in automated storage and retrieval systems, where they ensure accurate positioning and movement of goods. The versatility and durability of heavy-duty encoders make them suitable for use in harsh environments, such as in mining or construction equipment, where they provide reliable performance despite exposure to dust, dirt, and vibration. As industries continue to embrace automation and advanced technologies, the demand for heavy-duty encoders is expected to grow, driven by the need for precise and reliable motion control solutions. The ability of encoders to enhance operational efficiency, improve product quality, and reduce downtime makes them a critical component in modern industrial applications.

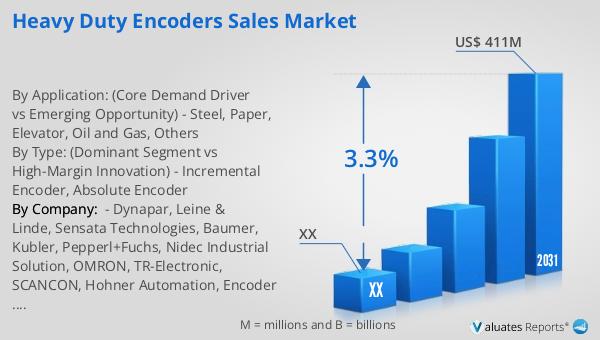

Global Heavy Duty Encoders Sales Market Outlook:

The global market for Heavy Duty Encoders was valued at approximately $329 million in 2024. Looking ahead, it is anticipated that the market will experience growth, reaching an estimated value of $411 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.3% over the forecast period from 2025 to 2031. This steady growth can be attributed to several factors, including the increasing adoption of automation technologies across various industries, which drives the demand for precise and reliable motion control solutions. As industries continue to evolve and embrace advanced technologies, the need for robust and durable encoders is expected to rise, contributing to the market's expansion. Additionally, technological advancements in encoder design and functionality are likely to enhance their appeal, further fueling market growth. The market's growth is also influenced by regional industrial development, regulatory standards, and economic conditions, which can impact the demand and supply dynamics. Overall, the Global Heavy Duty Encoders Sales Market is poised for steady growth, driven by the increasing demand for high-performance encoders in various industrial applications.

| Report Metric | Details |

| Report Name | Heavy Duty Encoders Sales Market |

| Forecasted market size in 2031 | US$ 411 million |

| CAGR | 3.3% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Dynapar, Leine & Linde, Sensata Technologies, Baumer, Kubler, Pepperl+Fuchs, Nidec Industrial Solution, OMRON, TR-Electronic, SCANCON, Hohner Automation, Encoder Products Company, Yuheng Optics, Lika Electronic |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |