What is Global High Pressure Processing (HPP) Food Sales Market?

The Global High Pressure Processing (HPP) Food Sales Market is a dynamic and rapidly evolving sector within the food industry. High Pressure Processing is a method used to preserve and sterilize food, which involves subjecting it to high levels of pressure. This process effectively eliminates harmful bacteria and pathogens without the need for heat, thus preserving the food's nutritional value, taste, and texture. The market for HPP foods is expanding as consumers increasingly demand fresh, natural, and minimally processed foods. This technology is particularly appealing because it extends the shelf life of products while maintaining their quality, which is a significant advantage for both manufacturers and consumers. The market is driven by the growing awareness of food safety and the increasing preference for clean-label products. As more companies adopt HPP technology, the market is expected to continue its upward trajectory, offering a wide range of opportunities for innovation and growth. The versatility of HPP makes it applicable to various food categories, including juices, meats, seafood, and ready-to-eat meals, further broadening its market potential.

in the Global High Pressure Processing (HPP) Food Sales Market:

In the Global High Pressure Processing (HPP) Food Sales Market, various types of HPP technologies are employed by different customers to meet their specific needs. One of the primary types is batch processing, which is widely used due to its simplicity and effectiveness. In batch processing, food products are placed in a chamber and subjected to high pressure for a set period. This method is particularly popular among small to medium-sized enterprises because it allows for flexibility in processing different types of food products without requiring significant changes to the equipment. Another type is continuous processing, which is more suitable for large-scale operations. Continuous HPP systems are designed to handle a constant flow of products, making them ideal for high-volume production environments. These systems are often used by large food manufacturers who need to process substantial quantities of food efficiently. Additionally, there is the semi-continuous processing type, which combines elements of both batch and continuous processing. This type offers a balance between flexibility and efficiency, making it a popular choice for companies that need to scale their operations without investing in entirely new systems. Each of these types has its advantages and is chosen based on factors such as production volume, product type, and specific business needs. For instance, companies producing juices and beverages often prefer continuous processing due to the high demand and the need for consistent quality. On the other hand, producers of specialty or niche products might opt for batch processing to maintain control over smaller production runs. The choice of HPP type also depends on the level of investment a company is willing to make. Batch systems generally require lower initial investment compared to continuous systems, which can be a deciding factor for startups or smaller companies. However, continuous systems, while more expensive, offer long-term cost savings through increased efficiency and reduced labor costs. Furthermore, the type of packaging used can influence the choice of HPP system. Some packaging materials are better suited for batch processing, while others are compatible with continuous systems. Companies must consider these factors when deciding on the type of HPP technology to implement. The versatility of HPP technology allows it to be adapted to various food products, including fruits, vegetables, meats, seafood, and dairy products. This adaptability is one of the reasons for its growing popularity in the food industry. As consumer preferences continue to shift towards healthier and more natural food options, the demand for HPP technology is expected to rise. Companies that can effectively leverage the different types of HPP systems to meet these demands will likely see significant growth in the coming years. The ability to offer high-quality, safe, and fresh products is a competitive advantage in today's market, and HPP technology provides the means to achieve this. As the market continues to evolve, we can expect to see further innovations in HPP technology, offering even more options for food manufacturers to enhance their product offerings.

in the Global High Pressure Processing (HPP) Food Sales Market:

The Global High Pressure Processing (HPP) Food Sales Market finds applications across a wide range of food categories, each benefiting from the unique advantages offered by HPP technology. One of the most significant applications is in the preservation of juices and beverages. HPP is particularly effective in maintaining the freshness and nutritional content of these products, which is a key selling point for health-conscious consumers. By using HPP, manufacturers can extend the shelf life of juices without the need for preservatives, appealing to the growing demand for clean-label products. Another important application is in the meat and seafood industry. HPP is used to enhance the safety and quality of these products by eliminating harmful bacteria and pathogens. This is especially crucial for ready-to-eat meats and seafood, where food safety is a top priority. The ability to offer safe, high-quality products without compromising on taste or texture is a significant advantage for companies in this sector. Additionally, HPP is used in the production of dairy products, such as cheese and yogurt. The technology helps in maintaining the freshness and flavor of these products while extending their shelf life. This is particularly beneficial for artisanal and specialty dairy producers who want to offer premium products without the use of artificial additives. The versatility of HPP also extends to the ready-to-eat meals market. As consumers increasingly seek convenient meal options that do not compromise on quality, HPP provides a solution by ensuring that these meals are safe, fresh, and flavorful. This application is particularly relevant in today's fast-paced world, where convenience and quality are highly valued. Furthermore, HPP is used in the processing of fruits and vegetables, helping to preserve their natural taste and nutritional value. This is especially important for products like guacamole and salsas, where freshness is a key attribute. By using HPP, manufacturers can offer products that meet consumer expectations for taste and quality while also ensuring food safety. The application of HPP technology is not limited to these categories, as it continues to expand into new areas of the food industry. As consumer preferences evolve and the demand for high-quality, minimally processed foods increases, the applications of HPP are likely to grow. Companies that can effectively leverage HPP technology to meet these demands will be well-positioned to succeed in the competitive food market. The ability to offer products that are safe, fresh, and free from artificial additives is a significant advantage in today's market, and HPP technology provides the means to achieve this. As the market continues to evolve, we can expect to see further innovations in HPP applications, offering even more opportunities for food manufacturers to enhance their product offerings.

Global High Pressure Processing (HPP) Food Sales Market Outlook:

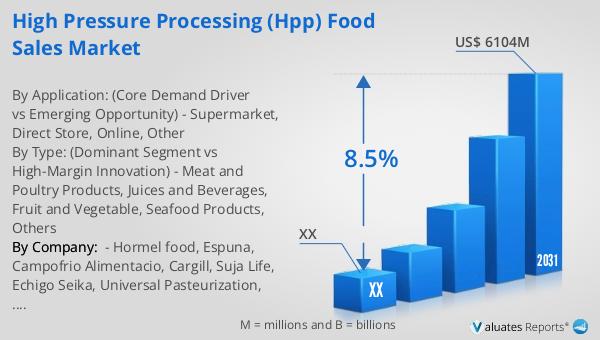

In 2024, the global market for High Pressure Processing (HPP) Food was valued at approximately $3,476 million. Looking ahead, it is anticipated that by 2031, this market will grow to an adjusted size of around $6,104 million, reflecting a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2025 to 2031. This growth trajectory underscores the increasing adoption and demand for HPP technology across the food industry. Notably, the top five manufacturers in this sector collectively hold nearly 55% of the market share, highlighting the competitive landscape and the dominance of key players. Within the product segments, fruits and vegetables emerge as the largest category, accounting for over 30% of the market share. This significant share indicates the strong consumer preference for fresh and minimally processed produce, which HPP technology effectively caters to. The market's expansion is driven by the growing awareness of food safety and the increasing demand for clean-label products. As more companies recognize the benefits of HPP, such as extended shelf life and preservation of nutritional value, the market is poised for continued growth. The versatility of HPP technology, applicable to a wide range of food categories, further enhances its market potential. As the industry evolves, the adoption of HPP is expected to increase, offering numerous opportunities for innovation and growth.

| Report Metric | Details |

| Report Name | High Pressure Processing (HPP) Food Sales Market |

| Forecasted market size in 2031 | US$ 6104 million |

| CAGR | 8.5% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Hormel food, Espuna, Campofrio Alimentacio, Cargill, Suja Life, Echigo Seika, Universal Pasteurization, Hain Celestial, Avure Technologies, Motivatit, Safe Pac Pasteurization |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |