What is Global Diaphragm Coupling Sales Market?

The Global Diaphragm Coupling Sales Market is a specialized segment within the broader mechanical coupling industry, focusing on the sale and distribution of diaphragm couplings worldwide. Diaphragm couplings are mechanical devices used to connect two shafts, allowing for the transmission of torque while accommodating misalignment between the shafts. These couplings are particularly valued for their ability to handle high torque loads and compensate for misalignments without causing undue stress on the connected machinery. The market encompasses a wide range of industries, including automotive, aerospace, and industrial machinery, where precision and reliability are paramount. The global market for diaphragm couplings is driven by the increasing demand for efficient and reliable power transmission solutions in various sectors. As industries continue to evolve and require more sophisticated machinery, the need for high-performance couplings like diaphragm couplings is expected to grow. This market is characterized by a mix of established players and emerging companies, all striving to innovate and offer products that meet the diverse needs of their customers. The market's growth is also influenced by technological advancements, which are leading to the development of more durable and efficient coupling solutions.

in the Global Diaphragm Coupling Sales Market:

In the Global Diaphragm Coupling Sales Market, various types of diaphragm couplings are utilized by customers based on their specific needs and applications. The most common types include single diaphragm couplings, double diaphragm couplings, and multiple diaphragm couplings. Single diaphragm couplings consist of a single flexible diaphragm that connects the two shafts. They are typically used in applications where space is limited and the required torque transmission is moderate. These couplings are known for their simplicity and ease of installation, making them a popular choice for smaller machinery and equipment. Double diaphragm couplings, on the other hand, feature two diaphragms connected by a spacer. This design allows for greater flexibility and the ability to handle higher torque loads compared to single diaphragm couplings. Double diaphragm couplings are often used in more demanding applications, such as in heavy machinery and industrial equipment, where reliability and performance are critical. Multiple diaphragm couplings, as the name suggests, consist of more than two diaphragms, providing even greater flexibility and torque transmission capabilities. These couplings are typically used in highly specialized applications where extreme precision and performance are required, such as in aerospace and high-performance automotive industries. Each type of diaphragm coupling offers unique advantages and is selected based on factors such as the level of misalignment, torque requirements, and environmental conditions. Customers in the Global Diaphragm Coupling Sales Market have a wide range of options to choose from, allowing them to find the perfect coupling solution for their specific needs. The choice of coupling type is often influenced by the specific requirements of the application, such as the need for high precision, the ability to handle high torque loads, and the ability to accommodate misalignment. In addition to the basic types of diaphragm couplings, there are also various materials and designs available to suit different applications. For example, some diaphragm couplings are made from stainless steel for increased durability and resistance to corrosion, while others may be made from lightweight materials such as aluminum for applications where weight is a concern. The design of the diaphragm itself can also vary, with some couplings featuring a convoluted diaphragm for increased flexibility and others featuring a flat diaphragm for simplicity and ease of manufacture. The choice of material and design is often influenced by factors such as the operating environment, the required lifespan of the coupling, and the cost considerations of the customer. Overall, the Global Diaphragm Coupling Sales Market offers a wide range of options for customers, allowing them to find the perfect coupling solution for their specific needs.

in the Global Diaphragm Coupling Sales Market:

The Global Diaphragm Coupling Sales Market serves a wide array of applications across various industries, each with its unique requirements and challenges. One of the primary applications of diaphragm couplings is in the automotive industry, where they are used in the powertrain systems of vehicles. In this context, diaphragm couplings help in transmitting power from the engine to the wheels while accommodating misalignments that may occur due to road conditions or vehicle dynamics. The ability of diaphragm couplings to handle high torque loads and provide reliable performance makes them an ideal choice for automotive applications. Another significant application of diaphragm couplings is in the aerospace industry, where they are used in aircraft engines and other critical systems. In aerospace applications, the need for lightweight, high-performance components is paramount, and diaphragm couplings meet these requirements by offering excellent torque transmission capabilities while being relatively lightweight. The precision and reliability of diaphragm couplings make them a preferred choice for aerospace engineers who demand the highest levels of performance and safety. In the industrial machinery sector, diaphragm couplings are used in a variety of equipment, including pumps, compressors, and turbines. These applications often involve high-speed operations and require couplings that can handle significant torque loads while maintaining alignment between the connected shafts. Diaphragm couplings are well-suited for these applications due to their ability to accommodate misalignments and provide smooth, efficient power transmission. Additionally, diaphragm couplings are used in the energy sector, particularly in wind turbines and other renewable energy systems. In these applications, the ability to handle variable loads and accommodate misalignments caused by environmental factors is crucial. Diaphragm couplings provide the necessary flexibility and reliability to ensure efficient power transmission in these demanding environments. The versatility of diaphragm couplings also extends to the marine industry, where they are used in ship propulsion systems and other critical applications. In marine environments, the ability to withstand harsh conditions, such as saltwater exposure and temperature fluctuations, is essential. Diaphragm couplings made from corrosion-resistant materials are particularly well-suited for these applications, providing reliable performance and longevity. Overall, the Global Diaphragm Coupling Sales Market caters to a diverse range of applications, each with its unique set of requirements. The ability of diaphragm couplings to provide reliable, efficient power transmission while accommodating misalignments makes them a valuable component in many industries. As technology continues to advance and industries evolve, the demand for high-performance diaphragm couplings is expected to grow, further expanding the range of applications for these versatile components.

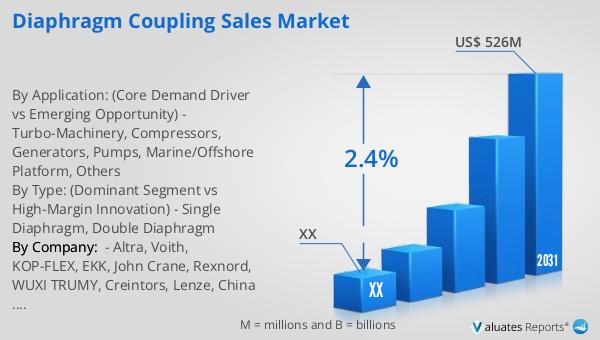

Global Diaphragm Coupling Sales Market Outlook:

In 2024, the global diaphragm coupling market was valued at approximately $447 million. By 2031, it is anticipated to reach an adjusted size of around $526 million, reflecting a compound annual growth rate (CAGR) of 2.4% during the forecast period from 2025 to 2031. This growth indicates a steady demand for diaphragm couplings across various industries, driven by the need for efficient and reliable power transmission solutions. The market is characterized by a competitive landscape, with the top five manufacturers holding a significant share of over 35%. This concentration of market share among leading players highlights the importance of innovation and quality in maintaining a competitive edge. Among the different product segments, the double diaphragm coupling stands out as the largest, accounting for over 60% of the market share. This dominance can be attributed to the superior performance and flexibility offered by double diaphragm couplings, making them a preferred choice for demanding applications. The market outlook suggests a positive trajectory for the diaphragm coupling industry, with opportunities for growth and expansion as industries continue to seek advanced coupling solutions to meet their evolving needs. The focus on technological advancements and the development of more durable and efficient coupling solutions will likely play a crucial role in shaping the future of the global diaphragm coupling market. As industries continue to evolve and require more sophisticated machinery, the need for high-performance couplings like diaphragm couplings is expected to grow. This market is characterized by a mix of established players and emerging companies, all striving to innovate and offer products that meet the diverse needs of their customers. The market's growth is also influenced by technological advancements, which are leading to the development of more durable and efficient coupling solutions.

| Report Metric | Details |

| Report Name | Diaphragm Coupling Sales Market |

| Forecasted market size in 2031 | US$ 526 million |

| CAGR | 2.4% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | Altra, Voith, KOP-FLEX, EKK, John Crane, Rexnord, WUXI TRUMY, Creintors, Lenze, China Chengdu Eastern-tech, RBK Drive, KTR, COUP-LINK, Miki Pulley |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |