What is Global Adhesives for Automotive Cameras and LiDAR Market?

The Global Adhesives for Automotive Cameras and LiDAR Market is a specialized segment within the automotive industry that focuses on the development and application of adhesive solutions specifically designed for automotive cameras and LiDAR systems. These adhesives play a crucial role in ensuring the stability, durability, and performance of these advanced technologies, which are integral to modern vehicles' safety and autonomous features. As automotive manufacturers increasingly integrate cameras and LiDAR systems into their vehicles for enhanced safety, navigation, and autonomous driving capabilities, the demand for high-performance adhesives has grown significantly. These adhesives must withstand various environmental conditions, such as temperature fluctuations, moisture, and vibrations, while maintaining strong bonding properties. The market encompasses a range of adhesive types, including single cure and dual cure adhesives, each offering unique benefits tailored to specific application requirements. As the automotive industry continues to evolve towards more advanced and autonomous vehicles, the Global Adhesives for Automotive Cameras and LiDAR Market is expected to expand, driven by technological advancements and the increasing adoption of these systems in vehicles worldwide.

Dual Cure Adhesive, Single Cure Adhesive in the Global Adhesives for Automotive Cameras and LiDAR Market:

Dual Cure Adhesives and Single Cure Adhesives are two primary types of adhesives used in the Global Adhesives for Automotive Cameras and LiDAR Market, each offering distinct advantages based on their curing processes and application requirements. Dual Cure Adhesives are designed to cure through two different mechanisms, typically involving a combination of UV light and heat or moisture. This dual curing process provides enhanced flexibility and reliability, making them ideal for applications where environmental conditions may vary or where a rapid initial cure is needed, followed by a secondary cure to ensure complete bonding. These adhesives are particularly beneficial in automotive applications where components are exposed to diverse conditions, as they offer strong adhesion, resistance to temperature fluctuations, and durability against vibrations and shocks. On the other hand, Single Cure Adhesives rely on a single curing mechanism, such as UV light, heat, or moisture, to achieve full bonding. These adhesives are often preferred for their simplicity and efficiency, as they require fewer steps and equipment for application. Single Cure Adhesives are widely used in automotive cameras and LiDAR systems due to their ease of use and ability to provide strong, reliable bonds in controlled environments. They are particularly effective in applications where rapid curing is essential, such as in high-volume manufacturing processes. Both Dual Cure and Single Cure Adhesives are engineered to meet the stringent requirements of automotive applications, ensuring that cameras and LiDAR systems remain securely attached and function optimally throughout the vehicle's lifespan. As the demand for advanced driver assistance systems (ADAS) and autonomous vehicles continues to rise, the development and application of these adhesives are expected to play a critical role in supporting the integration of these technologies into modern vehicles.

LiDAR, Camera in the Global Adhesives for Automotive Cameras and LiDAR Market:

The usage of Global Adhesives for Automotive Cameras and LiDAR Market in LiDAR and Camera applications is pivotal to the functionality and reliability of these systems in modern vehicles. In LiDAR applications, adhesives are used to secure the LiDAR sensors to the vehicle, ensuring precise alignment and stability. LiDAR systems, which use laser beams to measure distances and create detailed 3D maps of the vehicle's surroundings, require adhesives that can withstand environmental challenges such as temperature variations, moisture, and mechanical vibrations. The adhesives used in LiDAR applications must provide strong bonding to maintain the accuracy and performance of the sensors, which are critical for the vehicle's navigation and safety systems. Similarly, in camera applications, adhesives play a crucial role in mounting and securing cameras to the vehicle's body or interior. Automotive cameras are essential components of advanced driver assistance systems (ADAS), providing real-time visual data for features such as lane departure warnings, adaptive cruise control, and parking assistance. The adhesives used in these applications must offer excellent optical clarity, UV resistance, and durability to ensure that the cameras function effectively under various lighting and weather conditions. Additionally, these adhesives must be able to absorb shocks and vibrations to prevent misalignment or damage to the cameras. As the automotive industry continues to advance towards more autonomous and connected vehicles, the demand for reliable and high-performance adhesives in LiDAR and camera applications is expected to grow. These adhesives not only ensure the secure attachment of sensors and cameras but also contribute to the overall safety and efficiency of the vehicle's advanced systems.

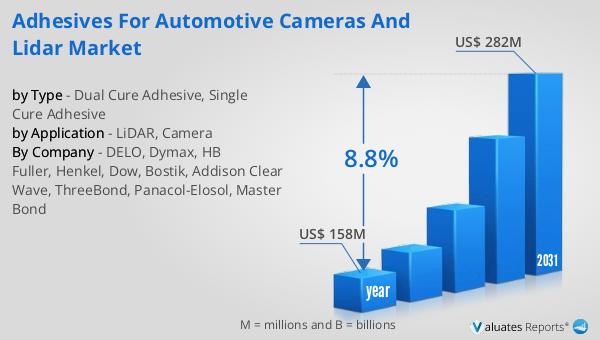

Global Adhesives for Automotive Cameras and LiDAR Market Outlook:

The global market for adhesives used in automotive cameras and LiDAR systems was valued at $158 million in 2024 and is anticipated to grow to $282 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.8% over the forecast period. This growth is driven by the increasing integration of advanced driver assistance systems (ADAS) and autonomous driving technologies in modern vehicles, which rely heavily on cameras and LiDAR systems for functionality. The market is dominated by the top five manufacturers, who collectively hold over 74% of the market share, indicating a highly competitive landscape with significant barriers to entry for new players. Within the product segment, single cure adhesives represent the largest share, accounting for over 60% of the market. This preference for single cure adhesives is attributed to their simplicity, efficiency, and ability to provide strong, reliable bonds in controlled environments, making them ideal for high-volume manufacturing processes. In terms of application, the camera segment is the largest, with a share exceeding 87%. This dominance is due to the widespread adoption of cameras in vehicles for various safety and navigation features, underscoring the critical role adhesives play in ensuring the performance and reliability of these systems. As the automotive industry continues to evolve, the demand for high-performance adhesives in camera and LiDAR applications is expected to remain robust, driven by technological advancements and the increasing adoption of these systems in vehicles worldwide.

| Report Metric | Details |

| Report Name | Adhesives for Automotive Cameras and LiDAR Market |

| Accounted market size in year | US$ 158 million |

| Forecasted market size in 2031 | US$ 282 million |

| CAGR | 8.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DELO, Dymax, HB Fuller, Henkel, Dow, Bostik, Addison Clear Wave, ThreeBond, Panacol-Elosol, Master Bond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |