What is Global Composite Material Mechanics Testing Market?

The Global Composite Material Mechanics Testing Market is a specialized sector focused on evaluating the mechanical properties of composite materials. These materials, which are made from two or more constituent materials with significantly different physical or chemical properties, are used extensively across various industries due to their enhanced strength, durability, and lightweight characteristics. The testing market is crucial as it ensures that these materials meet the required standards and specifications for safety and performance. This market encompasses a range of testing methods and equipment designed to assess various mechanical properties such as tensile strength, compression, impact resistance, and fatigue. The demand for composite material testing is driven by the increasing use of composites in industries like aerospace, automotive, and construction, where material performance is critical. As technology advances, the testing methods continue to evolve, offering more precise and reliable results. This market is expected to grow as industries increasingly adopt composite materials to improve product performance and efficiency. The testing ensures that the materials can withstand the operational stresses they will encounter, thereby guaranteeing safety and reliability in their applications.

Destructive Testing Method, Non-destructive Testing Method in the Global Composite Material Mechanics Testing Market:

Destructive Testing (DT) and Non-destructive Testing (NDT) are two primary methods used in the Global Composite Material Mechanics Testing Market to evaluate the properties and performance of composite materials. Destructive Testing involves physically breaking down the material to understand its structural limits and failure points. This method is crucial for determining the ultimate strength, ductility, and toughness of composite materials. Common DT methods include tensile testing, where a sample is pulled until it breaks to measure its tensile strength, and impact testing, which assesses the material's ability to absorb energy during a collision. While DT provides comprehensive data about the material's performance under extreme conditions, it results in the destruction of the test sample, making it unsuitable for finished products or expensive materials. On the other hand, Non-destructive Testing is a method that evaluates the properties of a material without causing any damage. NDT is essential for inspecting and testing materials in their final form, ensuring they meet quality standards without compromising their usability. Techniques such as ultrasonic testing, radiography, and thermography are commonly used in NDT. Ultrasonic testing uses high-frequency sound waves to detect internal flaws, while radiography employs X-rays or gamma rays to visualize the internal structure of the material. Thermography, on the other hand, uses infrared cameras to detect heat patterns and identify defects. NDT is particularly valuable in industries where safety and reliability are paramount, such as aerospace and automotive, as it allows for continuous monitoring and maintenance of materials in use. Both DT and NDT play a vital role in the composite material mechanics testing market, providing essential data that helps manufacturers and engineers ensure the quality and performance of their products. As the demand for composite materials grows, the testing methods continue to advance, offering more accurate and efficient ways to assess material properties. The choice between DT and NDT depends on the specific requirements of the application, the nature of the material, and the stage of the product lifecycle. While DT is often used in the research and development phase to understand material behavior, NDT is more commonly employed in quality control and maintenance to ensure ongoing performance and safety. Together, these testing methods contribute to the overall reliability and success of composite materials in various applications.

Aerospace & Defense, Transportation, Building & Construction, Wind Energy, Marine, Others in the Global Composite Material Mechanics Testing Market:

The Global Composite Material Mechanics Testing Market finds extensive usage across several key industries, each benefiting from the unique properties of composite materials. In the Aerospace & Defense sector, composite materials are crucial due to their lightweight and high-strength characteristics, which contribute to fuel efficiency and enhanced performance of aircraft and defense equipment. Testing in this sector ensures that materials can withstand extreme conditions such as high pressure, temperature fluctuations, and mechanical stress, which are common in aerospace applications. In the Transportation industry, composite materials are used to manufacture lighter and more fuel-efficient vehicles. Testing ensures that these materials meet safety standards and can endure the wear and tear of daily use. The Building & Construction industry utilizes composite materials for their durability and resistance to environmental factors. Testing in this sector focuses on ensuring that materials can withstand structural loads and environmental conditions such as moisture and temperature changes. In the Wind Energy sector, composite materials are used in the production of wind turbine blades due to their strength and lightweight properties. Testing ensures that these blades can withstand the mechanical stresses and environmental conditions they encounter during operation. The Marine industry benefits from composite materials' resistance to corrosion and lightweight properties, which are essential for building efficient and durable vessels. Testing ensures that these materials can withstand the harsh marine environment, including saltwater exposure and mechanical stress. Other industries, such as sports equipment and consumer goods, also utilize composite materials for their performance-enhancing properties. Testing in these areas ensures that products meet quality standards and provide the desired performance. Overall, the Global Composite Material Mechanics Testing Market plays a critical role in ensuring the safety, reliability, and performance of composite materials across various industries. As the demand for these materials continues to grow, the testing market will remain essential in supporting innovation and quality assurance.

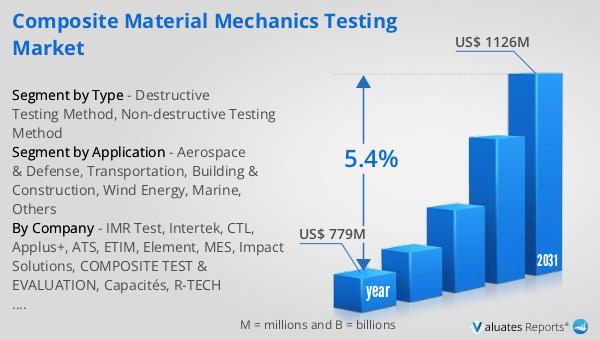

Global Composite Material Mechanics Testing Market Outlook:

The worldwide market for Composite Material Mechanics Testing was estimated to be worth $779 million in 2024. It is anticipated to expand to a revised valuation of $1,126 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. This growth is driven by the increasing adoption of composite materials across various industries, including aerospace, automotive, and construction, where the demand for lightweight, durable, and high-performance materials is rising. The testing market is essential in ensuring that these materials meet the necessary standards and specifications for safety and performance. As industries continue to innovate and develop new applications for composite materials, the need for reliable and accurate testing methods will grow. The market's expansion is also supported by advancements in testing technologies, which offer more precise and efficient ways to assess material properties. This growth trajectory highlights the importance of the Composite Material Mechanics Testing Market in supporting the development and application of composite materials across diverse sectors. As the market evolves, it will continue to play a crucial role in ensuring the quality and reliability of composite materials, contributing to the overall success and advancement of industries that rely on these innovative materials.

| Report Metric | Details |

| Report Name | Composite Material Mechanics Testing Market |

| Accounted market size in year | US$ 779 million |

| Forecasted market size in 2031 | US$ 1126 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | IMR Test, Intertek, CTL, Applus+, ATS, ETIM, Element, MES, Impact Solutions, COMPOSITE TEST & EVALUATION, Capacités, R-TECH Materials, ÉireComposites, Universallab, Westmoreland Mechanical Test & Research, NTS, Advanses, Instron, IMA Dresden |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |