What is Global Chemical Liquid Valve Market?

The Global Chemical Liquid Valve Market is a crucial segment within the broader industrial valve industry, focusing specifically on valves used to control the flow of chemical liquids. These valves are essential components in various industrial processes, ensuring the safe and efficient transport of chemicals. They are designed to withstand harsh conditions, including high pressure, temperature extremes, and corrosive substances, making them indispensable in industries such as chemical manufacturing, pharmaceuticals, oil and gas, and water treatment. The market encompasses a wide range of valve types, including ball valves, gate valves, globe valves, and butterfly valves, each serving specific functions depending on the application. The demand for chemical liquid valves is driven by the need for precise flow control and safety in handling hazardous materials. As industries continue to expand and modernize, the market for these valves is expected to grow, driven by technological advancements and the increasing complexity of industrial processes. The global market is characterized by a mix of established players and emerging companies, all striving to innovate and meet the evolving needs of their customers.

Automatic Equipment, Semi-Automatic Equipment, Manual Equipment in the Global Chemical Liquid Valve Market:

In the Global Chemical Liquid Valve Market, equipment is categorized into three main types: Automatic Equipment, Semi-Automatic Equipment, and Manual Equipment. Automatic Equipment is designed to operate without human intervention, using sensors and control systems to manage the flow of chemical liquids. These systems are highly efficient and are often used in large-scale industrial applications where precision and reliability are paramount. Automatic valves can be integrated into complex process control systems, allowing for real-time monitoring and adjustments to ensure optimal performance. This type of equipment is particularly beneficial in environments where safety and accuracy are critical, such as in chemical plants and refineries. Semi-Automatic Equipment, on the other hand, combines elements of both manual and automatic systems. These valves require some level of human interaction, typically for setup or adjustments, but can operate independently once configured. Semi-automatic systems offer a balance between control and automation, making them suitable for applications where full automation is not feasible or necessary. They provide flexibility and can be more cost-effective than fully automatic systems, especially in smaller operations or where budget constraints exist. Manual Equipment involves valves that are operated entirely by hand. These are the simplest and most traditional form of valve control, relying on human operators to open, close, or adjust the valve as needed. Manual valves are often used in applications where automation is not required or where the process is straightforward and does not demand constant monitoring. They are typically more affordable and easier to maintain than their automated counterparts, making them a practical choice for many industries. However, manual systems can be less efficient and may pose safety risks if not operated correctly, especially in environments dealing with hazardous chemicals. Each type of equipment has its advantages and limitations, and the choice between them depends on various factors, including the specific requirements of the application, budget considerations, and the level of control needed. As technology advances, the lines between these categories may blur, with more sophisticated semi-automatic systems offering features previously only available in fully automatic equipment. The ongoing development in sensor technology, control systems, and materials science continues to drive innovation in the valve market, providing industries with more options to enhance their operations.

Chemical Plant, Energy Extraction, Acid-Base Liquid Delivery, Others in the Global Chemical Liquid Valve Market:

The Global Chemical Liquid Valve Market plays a vital role in several key areas, including Chemical Plants, Energy Extraction, Acid-Base Liquid Delivery, and other industrial applications. In Chemical Plants, valves are essential for managing the flow of various chemical substances throughout the production process. They ensure that chemicals are transported safely and efficiently, preventing leaks and minimizing the risk of accidents. Valves in chemical plants must be highly durable and resistant to corrosion, as they often handle aggressive substances under high pressure and temperature conditions. The ability to precisely control the flow of chemicals is crucial for maintaining product quality and process efficiency. In the Energy Extraction sector, valves are used in the extraction and processing of oil, gas, and other energy resources. They are critical for controlling the flow of fluids in drilling operations, pipelines, and refineries. Valves in this sector must withstand extreme environmental conditions and provide reliable performance to ensure the safe and efficient transport of energy resources. The demand for energy continues to grow, driving the need for advanced valve solutions that can meet the challenges of modern extraction techniques. Acid-Base Liquid Delivery systems rely heavily on chemical liquid valves to manage the transport of corrosive substances. These systems are used in various industries, including pharmaceuticals, food and beverage, and water treatment. Valves in acid-base delivery systems must be constructed from materials that can resist chemical attack, ensuring long-term durability and safety. The precise control of acid and base flows is essential for maintaining the desired chemical balance in various processes. Beyond these specific areas, the Global Chemical Liquid Valve Market serves a wide range of other applications, from wastewater treatment to the production of consumer goods. In each of these applications, valves play a critical role in ensuring the safe and efficient transport of liquids, contributing to the overall success of industrial operations. As industries continue to evolve and face new challenges, the demand for innovative valve solutions will remain strong, driving ongoing growth and development in the market.

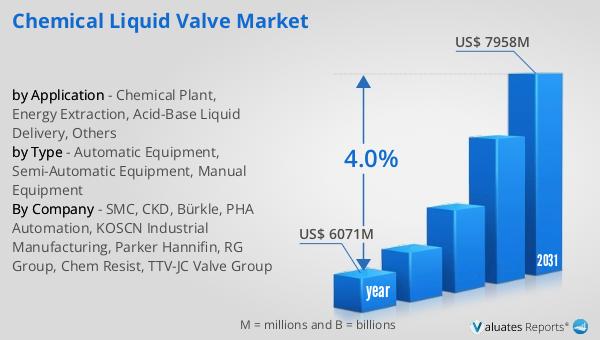

Global Chemical Liquid Valve Market Outlook:

The outlook for the Global Chemical Liquid Valve Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 6071 million, reflecting its importance across various industries. By 2031, it is projected to reach an impressive size of US$ 7958 million, growing at a compound annual growth rate (CAGR) of 4.0% during the forecast period. This growth is driven by several factors, including the increasing complexity of industrial processes, the need for enhanced safety measures, and the ongoing demand for efficient flow control solutions. As industries continue to expand and modernize, the role of chemical liquid valves becomes even more critical, ensuring the safe and efficient transport of hazardous materials. The market's expansion is also supported by technological advancements, which are leading to the development of more sophisticated and reliable valve solutions. Companies within the market are continually innovating to meet the evolving needs of their customers, offering products that are not only more efficient but also more environmentally friendly. As a result, the Global Chemical Liquid Valve Market is poised for continued growth, providing essential solutions to industries worldwide.

| Report Metric | Details |

| Report Name | Chemical Liquid Valve Market |

| Accounted market size in year | US$ 6071 million |

| Forecasted market size in 2031 | US$ 7958 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SMC, CKD, Bürkle, PHA Automation, KOSCN Industrial Manufacturing, Parker Hannifin, RG Group, Chem Resist, TTV-JC Valve Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |