What is Global Abrasive Metering Valve Market?

The Global Abrasive Metering Valve Market is a specialized segment within the broader industrial equipment sector, focusing on the precise control and regulation of abrasive materials used in various industrial processes. These valves are crucial in applications where the flow of abrasive materials needs to be meticulously managed to ensure efficiency, safety, and cost-effectiveness. Abrasive metering valves are employed in industries such as manufacturing, construction, and mining, where they help in controlling the flow of materials like sand, grit, and other abrasive substances. The market for these valves is driven by the increasing demand for precision in industrial processes, the need for reducing material wastage, and the growing emphasis on operational safety. As industries continue to evolve and adopt more advanced technologies, the demand for high-quality abrasive metering valves is expected to rise, making this market a vital component of the industrial equipment landscape. The market is characterized by a range of products designed to meet specific industrial needs, with manufacturers focusing on innovation and durability to cater to the diverse requirements of their clients.

Disc Style Valves, Plunger Style Valves, Ball Valves, Butterfly Valves in the Global Abrasive Metering Valve Market:

Disc Style Valves, Plunger Style Valves, Ball Valves, and Butterfly Valves are integral components of the Global Abrasive Metering Valve Market, each offering unique features and benefits tailored to specific industrial applications. Disc Style Valves are known for their simplicity and reliability, featuring a flat or slightly contoured disc that rotates to control the flow of abrasive materials. These valves are particularly effective in applications where a tight seal is essential to prevent leakage and ensure precise flow control. Their design allows for easy maintenance and replacement, making them a popular choice in industries where downtime needs to be minimized. Plunger Style Valves, on the other hand, utilize a linear motion to regulate the flow of materials. The plunger moves in and out of the valve body, allowing for precise control over the flow rate. This type of valve is ideal for applications requiring high precision and is often used in processes where the flow of abrasive materials needs to be adjusted frequently. Ball Valves are characterized by their spherical closure unit, which provides a quick and efficient means of controlling flow. The ball, with a hole through its center, rotates within the valve body to either allow or block the flow of materials. Ball Valves are highly durable and can handle high-pressure applications, making them suitable for use in harsh industrial environments. Their robust design ensures longevity and reliability, even in the most demanding conditions. Butterfly Valves, meanwhile, feature a disc that rotates around a central axis to regulate flow. These valves are known for their lightweight design and ease of operation, making them an excellent choice for applications where space and weight are critical considerations. Butterfly Valves offer a cost-effective solution for controlling the flow of abrasive materials, with the added benefit of quick operation and minimal maintenance requirements. Each of these valve types plays a crucial role in the Global Abrasive Metering Valve Market, providing industries with the tools they need to manage abrasive materials efficiently and effectively. Manufacturers continue to innovate and refine these products, ensuring they meet the evolving needs of their customers and remain competitive in a dynamic market.

Sander, Sandblaster, Shot Blasting, Others in the Global Abrasive Metering Valve Market:

The Global Abrasive Metering Valve Market finds extensive usage in various applications, including sanders, sandblasters, shot blasting, and other industrial processes. In the context of sanders, abrasive metering valves are essential for controlling the flow of abrasive materials used to smooth surfaces. These valves ensure that the right amount of abrasive is delivered to the sanding surface, optimizing the efficiency of the process and reducing material wastage. By providing precise control over the flow of abrasives, these valves help in achieving a consistent finish, which is crucial in industries such as woodworking, automotive, and metalworking. In sandblasting applications, abrasive metering valves play a critical role in regulating the flow of abrasive media used to clean or etch surfaces. The ability to control the flow rate of abrasives is vital in achieving the desired surface finish and ensuring the safety of the operation. These valves help in maintaining a consistent flow of abrasive materials, which is essential for achieving uniform results and preventing damage to the surface being treated. In shot blasting, abrasive metering valves are used to control the flow of shot or grit used to clean, strengthen, or polish metal surfaces. The precise control offered by these valves ensures that the right amount of abrasive is delivered to the surface, optimizing the efficiency of the process and reducing wear and tear on the equipment. This is particularly important in industries such as automotive, aerospace, and construction, where the quality of the surface finish is critical. Beyond these specific applications, abrasive metering valves are also used in a variety of other industrial processes where the flow of abrasive materials needs to be controlled. This includes applications such as waterjet cutting, where the precise control of abrasive flow is essential for achieving accurate cuts, and in mining operations, where these valves help in managing the flow of abrasive materials used in extraction processes. The versatility and precision offered by abrasive metering valves make them an indispensable tool in a wide range of industrial applications, contributing to improved efficiency, safety, and cost-effectiveness.

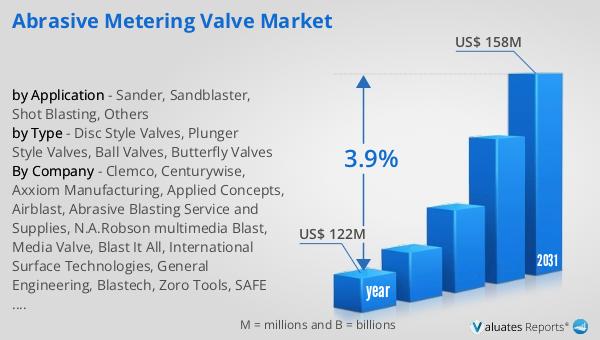

Global Abrasive Metering Valve Market Outlook:

The global market for Abrasive Metering Valves was valued at approximately $122 million in 2024, and it is anticipated to grow to a revised size of around $158 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.9% over the forecast period. This steady growth trajectory highlights the increasing demand for abrasive metering valves across various industries, driven by the need for precision and efficiency in industrial processes. As industries continue to evolve and adopt more advanced technologies, the demand for high-quality abrasive metering valves is expected to rise. The market's growth is also supported by the ongoing emphasis on operational safety and the need to reduce material wastage. Manufacturers in this market are focusing on innovation and durability to cater to the diverse requirements of their clients, ensuring that their products remain competitive in a dynamic market. The projected growth of the Global Abrasive Metering Valve Market underscores the importance of these valves in modern industrial processes and highlights the opportunities for manufacturers to expand their product offerings and reach new markets.

| Report Metric | Details |

| Report Name | Abrasive Metering Valve Market |

| Accounted market size in year | US$ 122 million |

| Forecasted market size in 2031 | US$ 158 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Clemco, Centurywise, Axxiom Manufacturing, Applied Concepts, Airblast, Abrasive Blasting Service and Supplies, N.A.Robson multimedia Blast, Media Valve, Blast It All, International Surface Technologies, General Engineering, Blastech, Zoro Tools, SAFE Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |