What is Global Angular Contact Bearing Rings Market?

The Global Angular Contact Bearing Rings Market is a specialized segment within the broader bearing industry, focusing on the production and distribution of angular contact bearing rings. These components are crucial in various mechanical systems, providing support and enabling rotational or linear movement with minimal friction. Angular contact bearing rings are designed to handle both radial and axial loads, making them versatile for numerous applications. They are commonly used in industries such as automotive, aerospace, machine tools, and robotics, where precision and reliability are paramount. The market for these bearing rings is driven by the increasing demand for high-performance machinery and equipment across different sectors. Technological advancements and the need for energy-efficient solutions further propel the growth of this market. Manufacturers are continually innovating to enhance the durability and efficiency of these rings, catering to the evolving needs of industries worldwide. As industries continue to expand and modernize, the demand for angular contact bearing rings is expected to rise, underscoring their importance in the global market landscape.

Ordinary Grade Rings, Precision Grade Rings in the Global Angular Contact Bearing Rings Market:

In the Global Angular Contact Bearing Rings Market, two primary types of rings are prevalent: Ordinary Grade Rings and Precision Grade Rings. Ordinary Grade Rings are typically used in applications where standard performance is sufficient. These rings are designed to handle moderate loads and speeds, making them suitable for general-purpose machinery and equipment. They are cost-effective and provide reliable performance in less demanding environments. On the other hand, Precision Grade Rings are engineered for high-performance applications where accuracy and reliability are critical. These rings are manufactured with tighter tolerances and superior materials, allowing them to withstand higher loads and speeds. Precision Grade Rings are essential in industries such as aerospace, robotics, and precision instruments, where even the slightest deviation can lead to significant issues. The choice between Ordinary and Precision Grade Rings depends on the specific requirements of the application, including load capacity, speed, and environmental conditions. Manufacturers in the Global Angular Contact Bearing Rings Market are continually innovating to improve the performance and durability of both types of rings, ensuring they meet the diverse needs of various industries. As technology advances and industries demand more efficient and reliable components, the distinction between Ordinary and Precision Grade Rings becomes increasingly important. Companies must carefully assess their needs and choose the appropriate type of ring to optimize performance and longevity. The ongoing development in materials and manufacturing processes also plays a crucial role in enhancing the capabilities of these rings, providing industries with the tools they need to succeed in a competitive global market.

Machine Tool Industry, Precision Instrument Industry, Automotive Industry, Aerospace Industry, Robotics Industry, Medical Industry, Others in the Global Angular Contact Bearing Rings Market:

The Global Angular Contact Bearing Rings Market finds extensive usage across various industries, each with unique requirements and challenges. In the Machine Tool Industry, these bearing rings are crucial for ensuring the precision and efficiency of machinery. They enable smooth and accurate movement, which is essential for producing high-quality components. The Precision Instrument Industry also relies heavily on angular contact bearing rings, as they provide the necessary accuracy and stability for sensitive equipment. In the Automotive Industry, these rings are used in various components, including transmissions and wheel hubs, where they help reduce friction and enhance performance. The Aerospace Industry demands high-performance bearing rings that can withstand extreme conditions and loads, making precision-grade rings a preferred choice. In the Robotics Industry, angular contact bearing rings are vital for enabling precise and controlled movements, which are crucial for the functionality of robotic systems. The Medical Industry also benefits from these rings, particularly in imaging equipment and surgical instruments, where precision and reliability are paramount. Other industries, such as renewable energy and construction, also utilize angular contact bearing rings to improve the efficiency and performance of their machinery. The versatility and reliability of these rings make them indispensable across various sectors, driving their demand in the global market.

Global Angular Contact Bearing Rings Market Outlook:

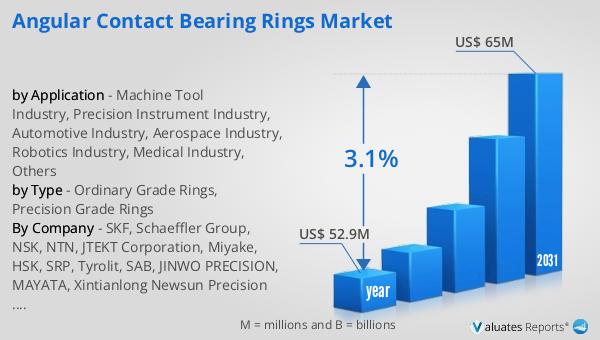

The global market for Angular Contact Bearing Rings was valued at approximately $52.9 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $65 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.1% over the forecast period. The market's expansion is driven by the increasing demand for high-performance machinery and equipment across various industries. As sectors such as automotive, aerospace, and robotics continue to evolve and modernize, the need for reliable and efficient bearing rings becomes more pronounced. Manufacturers are focusing on innovation and technological advancements to meet the growing demands of these industries. The development of new materials and manufacturing processes is also contributing to the market's growth, providing industries with more durable and efficient solutions. As the global economy continues to recover and industries invest in upgrading their equipment, the demand for angular contact bearing rings is expected to rise, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Angular Contact Bearing Rings Market |

| Accounted market size in year | US$ 52.9 million |

| Forecasted market size in 2031 | US$ 65 million |

| CAGR | 3.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Schaeffler Group, NSK, NTN, JTEKT Corporation, Miyake, HSK, SRP, Tyrolit, SAB, JINWO PRECISION, MAYATA, Xintianlong Newsun Precision Bearing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |