What is Global Airless Painting Sprayer Market?

The Global Airless Painting Sprayer Market is a dynamic and evolving sector within the broader painting and coating industry. Airless painting sprayers are devices that allow for the application of paint without the need for compressed air, using a high-pressure pump to atomize the paint into a fine spray. This technology is particularly valued for its efficiency and ability to provide a smooth, even coat over large surfaces quickly. The market for these sprayers is driven by their widespread use in various industries, including construction, automotive, and manufacturing, where they are used to apply coatings to buildings, vehicles, and machinery. The demand for airless painting sprayers is also fueled by the growing trend towards automation and the need for high-quality finishes in less time. As industries continue to seek ways to improve productivity and reduce labor costs, the adoption of airless painting sprayers is expected to rise. Additionally, advancements in technology have led to the development of more sophisticated and user-friendly models, further boosting their appeal. The market is characterized by a diverse range of products, catering to both professional and DIY users, with manufacturers continually innovating to meet the evolving needs of their customers.

Piston Pump, Diaphragm pump, Others in the Global Airless Painting Sprayer Market:

In the Global Airless Painting Sprayer Market, different types of pumps play a crucial role in determining the efficiency and effectiveness of the sprayers. The most common types of pumps used are piston pumps, diaphragm pumps, and others, each with its unique characteristics and applications. Piston pumps are known for their high pressure and ability to handle a wide range of viscosities, making them ideal for heavy-duty applications. They operate by using a piston to create a vacuum that draws the paint into the pump and then forces it out through the spray tip at high pressure. This type of pump is particularly suited for large-scale projects where a consistent and powerful spray is required. On the other hand, diaphragm pumps are known for their durability and ability to handle abrasive materials. They use a flexible diaphragm to move the paint, which reduces wear and tear on the pump components. This makes them ideal for applications where the paint contains solid particles or is highly viscous. Diaphragm pumps are often used in industrial settings where reliability and longevity are critical. Other types of pumps used in airless painting sprayers include gear pumps and peristaltic pumps, each with its advantages and limitations. Gear pumps are known for their precision and ability to handle low-viscosity materials, making them suitable for applications where accuracy is paramount. Peristaltic pumps, on the other hand, are known for their gentle handling of delicate materials, making them ideal for applications where the paint needs to be applied without damaging the substrate. The choice of pump in an airless painting sprayer depends on various factors, including the type of paint being used, the surface being coated, and the specific requirements of the project. Manufacturers in the Global Airless Painting Sprayer Market continue to innovate and develop new pump technologies to meet the evolving needs of their customers. This includes the development of pumps that are more energy-efficient, easier to maintain, and capable of handling a wider range of materials. As the demand for airless painting sprayers continues to grow, the role of pumps in determining the performance and reliability of these devices will remain a key focus for manufacturers and users alike.

Interior Renovation, Metal Anti-rust, Street Painting, Others in the Global Airless Painting Sprayer Market:

The Global Airless Painting Sprayer Market finds extensive usage across various applications, including interior renovation, metal anti-rust, street painting, and others. In interior renovation, airless painting sprayers are highly valued for their ability to provide a smooth and even finish on walls, ceilings, and other surfaces. They allow for quick and efficient application of paint, reducing the time and labor required for renovation projects. This makes them particularly popular among professional painters and contractors who need to complete projects within tight deadlines. The ability to apply a consistent coat of paint also ensures a high-quality finish, enhancing the overall appearance of the renovated space. In the realm of metal anti-rust applications, airless painting sprayers are used to apply protective coatings to metal surfaces, preventing corrosion and extending the lifespan of the material. The high-pressure spray ensures that the coating penetrates into all crevices and hard-to-reach areas, providing comprehensive protection against rust. This is particularly important in industries such as automotive and construction, where metal components are exposed to harsh environmental conditions. Street painting is another area where airless painting sprayers are widely used. They allow for the quick and efficient application of road markings, ensuring that streets and highways are clearly marked for safety and navigation. The ability to apply paint at high speed and with precision makes airless painting sprayers an essential tool for municipal and transportation departments. Other applications of airless painting sprayers include the coating of machinery and equipment, furniture finishing, and the application of specialty coatings such as fire retardants and waterproofing agents. The versatility and efficiency of airless painting sprayers make them an indispensable tool in a wide range of industries, contributing to their growing popularity in the global market.

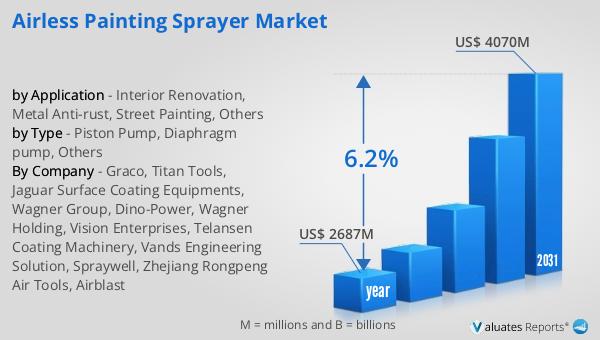

Global Airless Painting Sprayer Market Outlook:

The global market for airless painting sprayers was valued at approximately $2.687 billion in 2024. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $4.070 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% during the forecast period. The increasing demand for airless painting sprayers can be attributed to several factors, including the rising need for efficient and high-quality painting solutions across various industries. As businesses and consumers alike seek to improve productivity and reduce labor costs, the adoption of airless painting sprayers is expected to rise. Additionally, advancements in technology have led to the development of more sophisticated and user-friendly models, further boosting their appeal. The market is characterized by a diverse range of products, catering to both professional and DIY users, with manufacturers continually innovating to meet the evolving needs of their customers. As industries continue to seek ways to improve productivity and reduce labor costs, the adoption of airless painting sprayers is expected to rise. The market is characterized by a diverse range of products, catering to both professional and DIY users, with manufacturers continually innovating to meet the evolving needs of their customers. As the demand for airless painting sprayers continues to grow, the role of pumps in determining the performance and reliability of these devices will remain a key focus for manufacturers and users alike.

| Report Metric | Details |

| Report Name | Airless Painting Sprayer Market |

| Accounted market size in year | US$ 2687 million |

| Forecasted market size in 2031 | US$ 4070 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Graco, Titan Tools, Jaguar Surface Coating Equipments, Wagner Group, Dino-Power, Wagner Holding, Vision Enterprises, Telansen Coating Machinery, Vands Engineering Solution, Spraywell, Zhejiang Rongpeng Air Tools, Airblast |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |