What is Global Needle Sensor Market?

The Global Needle Sensor Market is a dynamic and rapidly evolving sector that plays a crucial role in various industries. Needle sensors are specialized devices designed to detect and measure specific parameters such as pressure, temperature, or chemical composition. These sensors are integral in applications where precision and accuracy are paramount. The market for needle sensors is driven by advancements in technology, increasing demand for automation, and the need for enhanced safety and efficiency in industrial processes. As industries continue to innovate and integrate more sophisticated systems, the demand for needle sensors is expected to grow. These sensors are used in a wide range of applications, from medical devices to environmental monitoring, showcasing their versatility and importance. The global needle sensor market is characterized by a diverse range of products and technologies, each tailored to meet the specific needs of different industries. As a result, companies operating in this market are continually investing in research and development to create more advanced and reliable sensors. This ongoing innovation is essential to meet the evolving demands of industries and to maintain a competitive edge in the market.

Contactless Sensor, Piercing Sensor in the Global Needle Sensor Market:

Contactless sensors and piercing sensors are two significant types of needle sensors that have distinct applications and advantages. Contactless sensors, as the name suggests, operate without the need for physical contact with the object being measured. This feature makes them ideal for applications where hygiene and contamination are concerns, such as in the medical and food industries. Contactless sensors use technologies like infrared, ultrasonic, or electromagnetic fields to detect changes in the environment or the object being monitored. These sensors are highly reliable and offer precise measurements, making them indispensable in scenarios where accuracy is critical. On the other hand, piercing sensors are designed to penetrate the surface of an object to measure internal parameters. These sensors are commonly used in applications where internal conditions need to be monitored, such as in the chemical and pharmaceutical industries. Piercing sensors provide direct and accurate readings of parameters like pressure, temperature, or chemical composition within a substance. This capability is crucial for processes that require precise control and monitoring to ensure quality and safety. Both contactless and piercing sensors have their unique advantages and are chosen based on the specific requirements of the application. The choice between these sensors depends on factors such as the nature of the material being measured, the required level of accuracy, and the environmental conditions. As technology continues to advance, the capabilities of both contactless and piercing sensors are expected to improve, offering even greater precision and reliability. This ongoing development is essential to meet the growing demands of industries and to address the challenges posed by increasingly complex processes. The global needle sensor market is poised for significant growth as industries continue to adopt these advanced technologies to enhance their operations and improve efficiency. Companies in this market are focused on developing innovative solutions that cater to the diverse needs of their customers, ensuring that they remain competitive in a rapidly changing landscape.

Medical, Chemical, Architecture, Environmental Protection, Others in the Global Needle Sensor Market:

The Global Needle Sensor Market finds extensive usage across various sectors, including medical, chemical, architecture, environmental protection, and others. In the medical field, needle sensors are crucial for monitoring vital parameters such as blood pressure, glucose levels, and other critical health indicators. These sensors provide accurate and real-time data, enabling healthcare professionals to make informed decisions and deliver better patient care. In the chemical industry, needle sensors are used to monitor and control processes, ensuring the quality and safety of chemical products. They help in detecting changes in pressure, temperature, and chemical composition, which are vital for maintaining the integrity of chemical processes. In architecture, needle sensors are employed to monitor structural integrity and environmental conditions. They provide valuable data that helps architects and engineers design safer and more efficient buildings. Environmental protection is another area where needle sensors play a significant role. They are used to monitor air and water quality, detect pollutants, and assess environmental conditions. This information is crucial for developing strategies to protect the environment and ensure sustainable development. In addition to these sectors, needle sensors are also used in various other industries, including automotive, aerospace, and manufacturing. Their versatility and precision make them indispensable tools for monitoring and controlling processes in these industries. As technology continues to advance, the applications of needle sensors are expected to expand, offering new opportunities for innovation and growth in the global market.

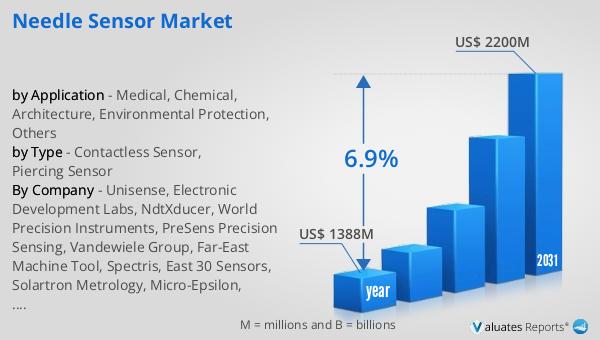

Global Needle Sensor Market Outlook:

The global needle sensor market is on a promising trajectory, with its valuation standing at approximately $1,388 million in 2024. This market is anticipated to experience substantial growth, reaching an estimated size of $2,200 million by 2031. This growth is driven by a compound annual growth rate (CAGR) of 6.9% over the forecast period. This upward trend reflects the increasing demand for needle sensors across various industries, driven by the need for precision, accuracy, and efficiency in monitoring and control processes. The market's expansion is fueled by advancements in technology, which have led to the development of more sophisticated and reliable sensors. These innovations are essential to meet the evolving needs of industries and to address the challenges posed by complex processes. As industries continue to adopt automation and integrate advanced technologies, the demand for needle sensors is expected to rise. This growth presents significant opportunities for companies operating in the global needle sensor market, as they strive to develop innovative solutions that cater to the diverse needs of their customers. The market's positive outlook is a testament to the importance of needle sensors in enhancing operational efficiency and ensuring safety and quality across various sectors.

| Report Metric | Details |

| Report Name | Needle Sensor Market |

| Accounted market size in year | US$ 1388 million |

| Forecasted market size in 2031 | US$ 2200 million |

| CAGR | 6.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Unisense, Electronic Development Labs, NdtXducer, World Precision Instruments, PreSens Precision Sensing, Vandewiele Group, Far-East Machine Tool, Spectris, East 30 Sensors, Solartron Metrology, Micro-Epsilon, Thermo-Electra, Shenzhen Merrytek Technology, UMS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |