What is Global Hot Rolled Coils Sales Market?

The Global Hot Rolled Coils Sales Market is a significant segment within the steel industry, focusing on the production and distribution of hot rolled coils. These coils are made by rolling steel at high temperatures, which is above the steel's recrystallization temperature. This process allows the steel to be shaped and formed easily, resulting in a product that is both durable and versatile. Hot rolled coils are widely used in various industries due to their strength and ability to be further processed into different forms. The market for these coils is driven by the demand from sectors such as construction, automotive, and manufacturing, where they are used in the production of structural components, machinery, and other essential products. The global market is characterized by a diverse range of manufacturers and suppliers, each competing to provide high-quality products to meet the growing needs of industries worldwide. As economies continue to develop and infrastructure projects expand, the demand for hot rolled coils is expected to remain robust, making this market a vital component of the global steel industry.

in the Global Hot Rolled Coils Sales Market:

The Global Hot Rolled Coils Sales Market caters to a variety of customer needs through its diverse range of product types. These types are primarily distinguished by their thickness, width, and specific properties tailored to different industrial applications. One of the most common types is the standard hot rolled coil, which is typically used in construction and infrastructure projects due to its strength and durability. These coils are often employed in the creation of beams, columns, and other structural elements that require robust materials. Another type is the high-strength low-alloy (HSLA) hot rolled coil, which offers enhanced mechanical properties and is used in applications where weight reduction is crucial without compromising strength. This makes HSLA coils ideal for the automotive industry, where they contribute to the production of lighter and more fuel-efficient vehicles. Additionally, there are hot rolled coils designed for specific applications such as shipbuilding, where the material must withstand harsh marine environments. These coils are treated to resist corrosion and provide long-lasting performance in challenging conditions. Furthermore, the market offers hot rolled coils with specialized coatings or finishes, such as galvanized or pickled and oiled coils, which provide additional protection against rust and improve surface quality for further processing. Customers in the manufacturing sector often prefer these coated coils for producing appliances, machinery, and other consumer goods that require a high-quality finish. The diversity in product types within the Global Hot Rolled Coils Sales Market ensures that customers across various industries can find the right material to meet their specific requirements, whether it's for constructing a skyscraper, building a car, or manufacturing household appliances. This adaptability and range of options make hot rolled coils an indispensable resource in the modern industrial landscape.

in the Global Hot Rolled Coils Sales Market:

Hot rolled coils find applications across a wide array of industries, each leveraging the material's unique properties to enhance their products and processes. In the construction industry, hot rolled coils are a fundamental component, used extensively in the creation of structural steel frameworks for buildings, bridges, and other infrastructure projects. Their strength and malleability make them ideal for forming beams, columns, and other critical structural elements that require durability and resilience. The automotive industry also heavily relies on hot rolled coils, particularly those with high-strength low-alloy compositions, to manufacture vehicle frames, chassis, and other components that demand both strength and weight efficiency. This application is crucial in the production of modern vehicles that aim to reduce fuel consumption and emissions. Additionally, hot rolled coils are used in the production of pipelines and storage tanks in the oil and gas industry, where their ability to withstand high pressure and temperature is essential. The manufacturing sector utilizes hot rolled coils in the production of machinery, equipment, and appliances, where the material's versatility allows for the creation of complex shapes and designs. Furthermore, hot rolled coils are employed in the shipbuilding industry, where their resistance to harsh marine environments is vital for constructing durable and long-lasting vessels. The agricultural sector also benefits from hot rolled coils, using them in the production of farming equipment and machinery that require robust and reliable materials. Overall, the diverse applications of hot rolled coils across these industries highlight their importance as a versatile and essential material in the global market.

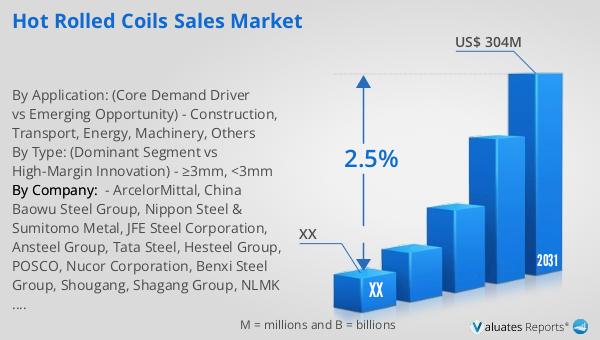

Global Hot Rolled Coils Sales Market Outlook:

In 2024, the global market for Hot Rolled Coils was valued at approximately $256 million. Looking ahead, projections indicate that by 2031, this market is expected to grow to a revised size of around $304 million, reflecting a compound annual growth rate (CAGR) of 2.5% during the forecast period from 2025 to 2031. This growth trajectory underscores the increasing demand for hot rolled coils across various industries. Notably, the market is dominated by the top five manufacturers, who collectively hold a significant share of over 45%. This concentration of market power among leading producers highlights the competitive nature of the industry and the importance of innovation and efficiency in maintaining market position. In terms of product segmentation, coils with a thickness of 3mm represent the largest segment, accounting for more than 65% of the market share. This preference for 3mm coils is likely due to their versatility and suitability for a wide range of applications, from construction to automotive manufacturing. As the market continues to evolve, these dynamics will play a crucial role in shaping the strategies of manufacturers and suppliers in the Global Hot Rolled Coils Sales Market.

| Report Metric | Details |

| Report Name | Hot Rolled Coils Sales Market |

| Forecasted market size in 2031 | US$ 304 million |

| CAGR | 2.5% |

| Forecasted years | 2025 - 2031 |

| By Type: (Dominant Segment vs High-Margin Innovation) |

|

| By Application: (Core Demand Driver vs Emerging Opportunity) |

|

| By Region |

|

| By Company: | ArcelorMittal, China Baowu Steel Group, Nippon Steel & Sumitomo Metal, JFE Steel Corporation, Ansteel Group, Tata Steel, Hesteel Group, POSCO, Nucor Corporation, Benxi Steel Group, Shougang, Shagang Group, NLMK Group, ThyssenKrupp, JSW Steel Ltd, Maanshan Steel, United States Steel Corporation, Jianlong Group, Valin Steel Group, Steel Authority of India Limited, China Steel Corporation, Hyundai Steel, Jingye Steel, Gerdau |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |