What is Global Intelligent PCB Board Defect Detection System Market?

The Global Intelligent PCB Board Defect Detection System Market is a rapidly evolving sector that focuses on the development and deployment of advanced technologies to identify defects in printed circuit boards (PCBs). These systems are crucial in ensuring the quality and reliability of PCBs, which are integral components in a wide range of electronic devices. The market is driven by the increasing demand for high-quality electronic products and the need for efficient and accurate defect detection methods. Intelligent PCB defect detection systems utilize cutting-edge technologies such as machine learning, artificial intelligence, and advanced imaging techniques to detect and classify defects with high precision. These systems are designed to identify various types of defects, including surface defects, soldering issues, and component misalignments, among others. The adoption of these systems is growing across various industries, including consumer electronics, automotive, and telecommunications, as manufacturers strive to enhance product quality and reduce production costs. The market is characterized by continuous technological advancements and innovations aimed at improving detection accuracy and speed, thereby driving its growth and expansion.

Automatic Optical Inspection Technology (AOI)), X-ray Inspection (AXI), Others in the Global Intelligent PCB Board Defect Detection System Market:

Automatic Optical Inspection (AOI) technology is a critical component of the Global Intelligent PCB Board Defect Detection System Market. AOI systems use high-resolution cameras and sophisticated algorithms to capture images of PCBs and analyze them for defects. This technology is highly effective in detecting surface defects such as scratches, stains, and soldering issues. AOI systems are valued for their speed and accuracy, allowing manufacturers to inspect large volumes of PCBs quickly and efficiently. The integration of artificial intelligence and machine learning into AOI systems has further enhanced their capabilities, enabling them to learn from previous inspections and improve their defect detection accuracy over time. X-ray Inspection (AXI) technology, on the other hand, is used to detect defects that are not visible on the surface of PCBs. AXI systems use X-rays to penetrate the layers of a PCB and identify hidden defects such as voids, misalignments, and solder joint issues. This technology is particularly useful for inspecting complex multilayer PCBs and components with hidden solder joints. AXI systems provide a non-destructive inspection method, ensuring that PCBs remain intact during the inspection process. Other technologies used in the Global Intelligent PCB Board Defect Detection System Market include laser-based inspection systems and ultrasonic testing. Laser-based systems use laser beams to scan PCBs and detect surface irregularities, while ultrasonic testing uses high-frequency sound waves to identify defects within the PCB structure. These technologies complement AOI and AXI systems, providing manufacturers with a comprehensive suite of tools for defect detection. The integration of these technologies into intelligent defect detection systems has revolutionized the PCB inspection process, enabling manufacturers to achieve higher levels of quality control and reduce the risk of defective products reaching the market. As the demand for high-quality electronic products continues to grow, the adoption of these advanced defect detection technologies is expected to increase, driving further innovation and development in the market.

Consumer Electronics, Automotive Electronics, Communication Equipment, Others in the Global Intelligent PCB Board Defect Detection System Market:

The Global Intelligent PCB Board Defect Detection System Market plays a vital role in various industries, including consumer electronics, automotive electronics, communication equipment, and others. In the consumer electronics sector, these systems are used to ensure the quality and reliability of PCBs used in devices such as smartphones, tablets, and laptops. The high demand for consumer electronics with advanced features and functionalities necessitates the use of intelligent defect detection systems to maintain product quality and reduce the risk of defects. In the automotive electronics industry, intelligent PCB defect detection systems are used to inspect PCBs used in various automotive applications, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The automotive industry requires high levels of reliability and safety, making defect detection systems essential for ensuring the quality of electronic components. In the communication equipment sector, these systems are used to inspect PCBs used in devices such as routers, switches, and base stations. The increasing demand for high-speed and reliable communication networks drives the need for high-quality PCBs, making defect detection systems crucial for maintaining product quality. Other industries that benefit from the Global Intelligent PCB Board Defect Detection System Market include aerospace, medical devices, and industrial equipment. In the aerospace industry, these systems are used to inspect PCBs used in avionics and other critical systems, where reliability and safety are paramount. In the medical devices industry, defect detection systems are used to ensure the quality of PCBs used in devices such as diagnostic equipment and patient monitoring systems. The industrial equipment sector also relies on these systems to inspect PCBs used in various applications, including automation and control systems. The widespread adoption of intelligent PCB defect detection systems across these industries highlights their importance in ensuring product quality and reliability, driving the growth and expansion of the market.

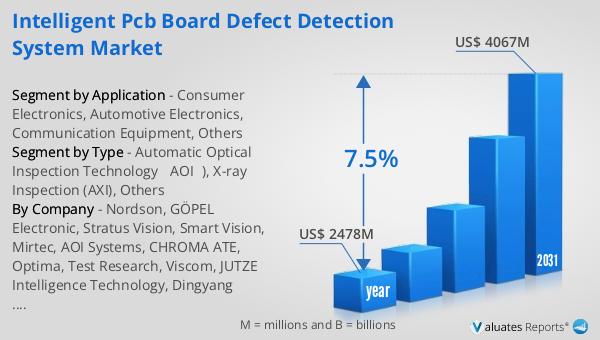

Global Intelligent PCB Board Defect Detection System Market Outlook:

The global market for Intelligent PCB Board Defect Detection Systems was valued at $2,478 million in 2024 and is anticipated to grow to a revised size of $4,067 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.5% during the forecast period. This growth is driven by the increasing demand for high-quality electronic products and the need for efficient and accurate defect detection methods. As industries such as consumer electronics, automotive, and telecommunications continue to expand, the demand for reliable and high-performance PCBs is expected to rise, further fueling the growth of the market. The integration of advanced technologies such as artificial intelligence, machine learning, and advanced imaging techniques into defect detection systems has enhanced their capabilities, enabling manufacturers to achieve higher levels of quality control and reduce production costs. The market is characterized by continuous technological advancements and innovations aimed at improving detection accuracy and speed, driving its growth and expansion. As the demand for high-quality electronic products continues to grow, the adoption of these advanced defect detection technologies is expected to increase, driving further innovation and development in the market. The growth of the Global Intelligent PCB Board Defect Detection System Market reflects the increasing importance of quality control and reliability in the production of electronic devices, highlighting the critical role these systems play in ensuring the quality and performance of PCBs.

| Report Metric | Details |

| Report Name | Intelligent PCB Board Defect Detection System Market |

| Accounted market size in year | US$ 2478 million |

| Forecasted market size in 2031 | US$ 4067 million |

| CAGR | 7.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nordson, GÖPEL Electronic, Stratus Vision, Smart Vision, Mirtec, AOI Systems, CHROMA ATE, Optima, Test Research, Viscom, JUTZE Intelligence Technology, Dingyang Technology, CyberOptics, Orbotech, Takano, Jingce Electronics, Northeast Control, Sunny Optical, Shennan Circuits, Semy Control |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |