What is Global Plate Heat Exchanger Gasket Market?

The Global Plate Heat Exchanger Gasket Market is a crucial segment within the broader heat exchanger industry, focusing on the production and distribution of gaskets used in plate heat exchangers. These gaskets are essential components that ensure the efficient operation of heat exchangers by providing a seal between the plates, preventing leaks, and maintaining pressure. The market is driven by the increasing demand for energy-efficient systems across various industries, including HVAC, oil and gas, and power generation. As industries strive to optimize energy use and reduce operational costs, the demand for reliable and durable gaskets has surged. The market is characterized by a diverse range of products, including glued and free-glued gaskets, each offering unique benefits and applications. Technological advancements and innovations in material science have further propelled the market, enabling the development of gaskets that can withstand extreme temperatures and pressures. Additionally, the growing emphasis on sustainability and environmental regulations has led to the adoption of gaskets that enhance the efficiency of heat exchangers, thereby reducing energy consumption and emissions. Overall, the Global Plate Heat Exchanger Gasket Market plays a vital role in supporting industrial operations and promoting energy efficiency across various sectors.

Glued Gaskets, Free-glued (Clipped) Gaskets in the Global Plate Heat Exchanger Gasket Market:

Glued gaskets and free-glued (clipped) gaskets are two primary types of gaskets used in the Global Plate Heat Exchanger Gasket Market, each serving distinct purposes and offering unique advantages. Glued gaskets are permanently attached to the heat exchanger plates using adhesive materials. This type of gasket is known for its robust sealing capabilities, ensuring that there are no leaks between the plates. The adhesive used in glued gaskets is typically resistant to high temperatures and pressures, making them suitable for applications in harsh environments. One of the main advantages of glued gaskets is their ability to provide a consistent and reliable seal, which is crucial for maintaining the efficiency and safety of heat exchangers. However, the permanent nature of glued gaskets can also be a disadvantage, as it makes them difficult to replace or repair. In contrast, free-glued or clipped gaskets are not permanently attached to the plates. Instead, they are held in place by clips or other mechanical means. This design allows for easy removal and replacement of the gaskets, making maintenance and repairs more straightforward. Free-glued gaskets are often preferred in applications where frequent maintenance is required, as they can be quickly and easily replaced without the need for specialized tools or adhesives. Additionally, the flexibility of free-glued gaskets allows them to accommodate slight misalignments between the plates, ensuring a secure seal even in less-than-ideal conditions. Despite their advantages, free-glued gaskets may not provide the same level of sealing performance as glued gaskets, particularly in high-pressure or high-temperature applications. The choice between glued and free-glued gaskets often depends on the specific requirements of the application, including factors such as operating conditions, maintenance needs, and cost considerations. In the Global Plate Heat Exchanger Gasket Market, glued gaskets hold a dominant position, accounting for a significant share of the market. This is largely due to their superior sealing capabilities and durability, which make them ideal for demanding applications in industries such as oil and gas, power generation, and chemical processing. However, the demand for free-glued gaskets is also growing, driven by the need for flexible and easily maintainable solutions in sectors such as HVAC and food and beverage processing. As the market continues to evolve, manufacturers are investing in research and development to improve the performance and versatility of both glued and free-glued gaskets, ensuring that they can meet the diverse needs of their customers. Overall, the choice between glued and free-glued gaskets is a critical consideration for businesses operating in the Global Plate Heat Exchanger Gasket Market, as it can significantly impact the efficiency, reliability, and cost-effectiveness of their heat exchanger systems.

HVAC & Refrigeration, Oil & Gas, Power Generation, Chemical, Food & Beverage, Pharmaceutical, Others in the Global Plate Heat Exchanger Gasket Market:

The Global Plate Heat Exchanger Gasket Market finds extensive usage across various industries, each with unique requirements and challenges. In the HVAC and refrigeration sector, plate heat exchanger gaskets are crucial for maintaining efficient thermal management systems. These gaskets ensure that heat exchangers operate effectively, providing optimal temperature control and energy efficiency in heating, ventilation, and air conditioning systems. In the oil and gas industry, plate heat exchanger gaskets are used in a variety of applications, including refining, petrochemical processing, and offshore drilling. The gaskets must withstand extreme temperatures and pressures, ensuring the safe and efficient operation of heat exchangers in these demanding environments. In power generation, plate heat exchanger gaskets play a vital role in maintaining the efficiency of cooling systems, which are essential for preventing overheating and ensuring the reliable operation of power plants. The chemical industry also relies heavily on plate heat exchanger gaskets for processes such as heating, cooling, and condensing. These gaskets must be resistant to corrosive chemicals and high temperatures, ensuring the safe and efficient operation of heat exchangers in chemical processing plants. In the food and beverage industry, plate heat exchanger gaskets are used in applications such as pasteurization, sterilization, and cooling. The gaskets must meet strict hygiene standards and be resistant to food-grade chemicals, ensuring the safety and quality of food and beverage products. The pharmaceutical industry also relies on plate heat exchanger gaskets for processes such as heating, cooling, and sterilization. The gaskets must meet stringent regulatory requirements and be resistant to pharmaceutical-grade chemicals, ensuring the safety and efficacy of pharmaceutical products. In addition to these industries, plate heat exchanger gaskets are used in a variety of other applications, including marine, automotive, and renewable energy. The versatility and reliability of plate heat exchanger gaskets make them an essential component in a wide range of industrial processes, supporting energy efficiency and operational reliability across diverse sectors.

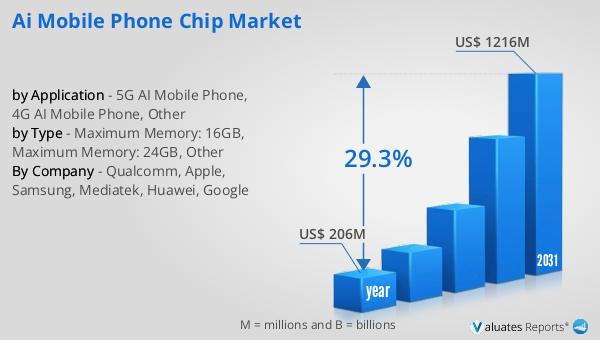

Global Plate Heat Exchanger Gasket Market Outlook:

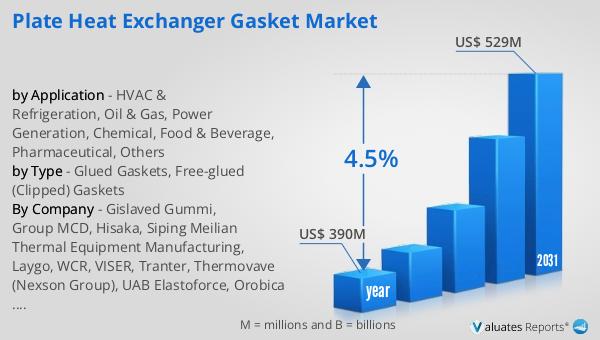

The global market for Plate Heat Exchanger Gasket was valued at $390 million in 2024 and is anticipated to grow to a revised size of $529 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period. Within this market, glued gaskets hold a dominant position, capturing a significant market share of up to 80.93%. This dominance is attributed to their superior sealing capabilities and durability, which make them ideal for demanding applications in industries such as oil and gas, power generation, and chemical processing. From an application perspective, the HVAC and refrigeration sector, along with the oil and gas industry, are the primary users of plate heat exchanger gaskets, accounting for 21.81% and 24.61% of the total market, respectively. The demand for energy-efficient systems and the need for reliable thermal management solutions drive the adoption of plate heat exchanger gaskets in these sectors. As industries continue to prioritize energy efficiency and operational reliability, the Global Plate Heat Exchanger Gasket Market is expected to experience steady growth, supported by technological advancements and innovations in material science. The market's expansion is further fueled by the increasing emphasis on sustainability and environmental regulations, which encourage the adoption of gaskets that enhance the efficiency of heat exchangers, thereby reducing energy consumption and emissions. Overall, the Global Plate Heat Exchanger Gasket Market plays a vital role in supporting industrial operations and promoting energy efficiency across various sectors.

| Report Metric | Details |

| Report Name | Plate Heat Exchanger Gasket Market |

| Accounted market size in year | US$ 390 million |

| Forecasted market size in 2031 | US$ 529 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Gislaved Gummi, Group MCD, Hisaka, Siping Meilian Thermal Equipment Manufacturing, Laygo, WCR, VISER, Tranter, Thermovave (Nexson Group), UAB Elastoforce, Orobica Plast-Gom, Cipriani, AGC Heat Transfer, PHE Nordic, Renocol, HFM, Varalka PHE, Spetech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |