What is Global Underground Mining Monitoring Market?

The Global Underground Mining Monitoring Market is a specialized segment within the broader mining industry that focuses on the use of advanced technologies to monitor and manage underground mining operations. This market encompasses a range of solutions designed to enhance safety, efficiency, and productivity in underground mines. These solutions include sensors, software, and communication systems that provide real-time data on various aspects of mining operations, such as air quality, equipment performance, and structural integrity. By leveraging these technologies, mining companies can detect potential hazards, optimize resource extraction, and reduce operational costs. The market is driven by the increasing demand for minerals and metals, coupled with the need for safer and more efficient mining practices. As mining operations become more complex and regulations become stricter, the adoption of underground mining monitoring solutions is expected to grow. This market is characterized by continuous innovation, with companies investing in research and development to create more sophisticated and reliable monitoring systems. Overall, the Global Underground Mining Monitoring Market plays a crucial role in ensuring the sustainability and safety of mining operations worldwide.

Continuous Monitoring, Non-continuous Monitoring in the Global Underground Mining Monitoring Market:

Continuous Monitoring and Non-continuous Monitoring are two critical approaches within the Global Underground Mining Monitoring Market, each serving distinct purposes and offering unique benefits. Continuous Monitoring involves the real-time collection and analysis of data from various sensors and devices installed throughout the mining site. This approach allows for the constant surveillance of critical parameters such as air quality, gas levels, temperature, and equipment performance. By providing immediate feedback, continuous monitoring enables mining operators to quickly identify and address potential issues, thereby enhancing safety and operational efficiency. For instance, if gas levels rise to dangerous levels, the system can trigger alarms and initiate evacuation procedures, preventing accidents and ensuring the safety of workers. Additionally, continuous monitoring helps in optimizing resource extraction by providing insights into equipment performance and operational conditions, allowing for timely maintenance and adjustments. On the other hand, Non-continuous Monitoring involves periodic data collection and analysis, typically conducted at specific intervals or in response to particular events. This approach is often used for less critical parameters or in situations where continuous monitoring is not feasible due to technical or financial constraints. Non-continuous monitoring can be effective in assessing long-term trends and patterns, providing valuable insights into the overall health and performance of the mining operation. For example, periodic inspections and measurements can help identify structural changes in the mine, assess the effectiveness of ventilation systems, and evaluate the impact of mining activities on the surrounding environment. While non-continuous monitoring may not offer the immediacy of continuous monitoring, it can still play a vital role in ensuring the long-term sustainability and safety of mining operations. Both continuous and non-continuous monitoring approaches have their advantages and limitations, and the choice between them often depends on the specific needs and constraints of the mining operation. In many cases, a combination of both approaches is used to achieve a comprehensive monitoring strategy. By integrating continuous and non-continuous monitoring systems, mining companies can benefit from the immediacy of real-time data and the depth of periodic assessments, creating a robust framework for managing underground mining operations. This integrated approach not only enhances safety and efficiency but also supports compliance with regulatory requirements and industry standards. As the Global Underground Mining Monitoring Market continues to evolve, the development and adoption of advanced monitoring technologies are expected to play a pivotal role in shaping the future of the mining industry.

Coal Mine, Metal Mine, Others in the Global Underground Mining Monitoring Market:

The Global Underground Mining Monitoring Market finds significant application in various types of mines, including coal mines, metal mines, and others. In coal mines, monitoring systems are crucial for ensuring the safety of workers and the efficiency of operations. Coal mining is inherently hazardous due to the presence of explosive gases and the risk of structural collapses. Monitoring systems equipped with gas sensors, air quality monitors, and structural integrity sensors provide real-time data that helps in detecting potential hazards and preventing accidents. By continuously monitoring gas levels and air quality, mining operators can take proactive measures to mitigate risks, such as adjusting ventilation systems or evacuating workers in case of dangerous conditions. Additionally, monitoring systems help optimize coal extraction processes by providing insights into equipment performance and operational conditions, leading to improved productivity and reduced operational costs. In metal mines, the focus of monitoring systems is often on ensuring the structural stability of the mine and optimizing resource extraction. Metal mining involves the removal of large volumes of earth and rock, which can impact the stability of the mine and the surrounding environment. Monitoring systems equipped with geotechnical sensors and environmental monitors provide valuable data on ground movement, rock stress, and environmental conditions. This information helps mining operators assess the stability of the mine and make informed decisions about excavation and support strategies. By optimizing resource extraction processes, monitoring systems contribute to increased efficiency and reduced environmental impact. Furthermore, monitoring systems play a crucial role in ensuring compliance with environmental regulations and industry standards, helping mining companies maintain their social license to operate. Beyond coal and metal mines, the Global Underground Mining Monitoring Market also serves other types of mines, such as those extracting minerals like salt, potash, and gypsum. In these mines, monitoring systems are used to ensure the safety of workers and the efficiency of operations. For example, in salt mines, monitoring systems equipped with humidity and temperature sensors help maintain optimal conditions for salt extraction and storage. In potash mines, monitoring systems provide data on ground stability and environmental conditions, helping operators manage the unique challenges associated with potash extraction. Overall, the application of monitoring systems in various types of mines underscores the importance of advanced technologies in enhancing the safety, efficiency, and sustainability of mining operations. As the demand for minerals and metals continues to grow, the role of the Global Underground Mining Monitoring Market in supporting safe and efficient mining practices is expected to become increasingly important.

Global Underground Mining Monitoring Market Outlook:

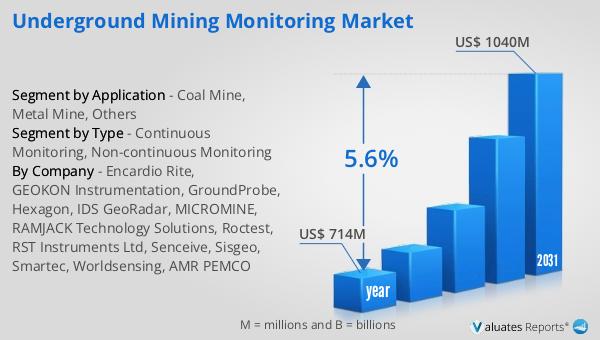

In 2024, the global market for Underground Mining Monitoring was valued at approximately $714 million. This market is anticipated to experience significant growth over the coming years, with projections indicating that it will reach an estimated size of $1,040 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.6% during the forecast period. The expansion of this market can be attributed to several factors, including the increasing demand for minerals and metals, the need for enhanced safety measures in mining operations, and the adoption of advanced monitoring technologies. As mining companies strive to improve operational efficiency and comply with stringent regulatory requirements, the demand for sophisticated monitoring solutions is expected to rise. These solutions not only enhance safety and productivity but also support sustainable mining practices by minimizing environmental impact and optimizing resource extraction. The projected growth of the Global Underground Mining Monitoring Market reflects the industry's commitment to leveraging technology to address the challenges and opportunities of modern mining operations. As the market continues to evolve, it is likely to witness further innovation and investment, driving the development of more advanced and reliable monitoring systems.

| Report Metric | Details |

| Report Name | Underground Mining Monitoring Market |

| Accounted market size in year | US$ 714 million |

| Forecasted market size in 2031 | US$ 1040 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Encardio Rite, GEOKON Instrumentation, GroundProbe, Hexagon, IDS GeoRadar, MICROMINE, RAMJACK Technology Solutions, Roctest, RST Instruments Ltd, Senceive, Sisgeo, Smartec, Worldsensing, AMR PEMCO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |