What is Global Circumfluent Cyclone Separator Market?

The Global Circumfluent Cyclone Separator Market is a specialized segment within the broader industrial equipment market, focusing on devices designed to separate particles from a fluid, typically air or liquid, using a vortex separation process. These separators are crucial in various industries for their ability to efficiently remove particulates from gases or liquids, thereby improving the quality and purity of the output. The market for these separators is driven by the increasing demand for cleaner industrial processes and the need to comply with stringent environmental regulations. As industries continue to expand and environmental concerns grow, the demand for effective separation technologies like circumfluent cyclone separators is expected to rise. These devices are particularly valued for their efficiency, low maintenance requirements, and ability to handle large volumes of fluid, making them an essential component in sectors such as oil and gas, chemical processing, and manufacturing. The market is characterized by a range of products varying in size and capacity, tailored to meet the specific needs of different industrial applications.

Small Separator, Large Separator in the Global Circumfluent Cyclone Separator Market:

In the Global Circumfluent Cyclone Separator Market, separators are typically categorized into small and large separators, each serving distinct purposes based on their size and capacity. Small separators are designed for applications where space is limited or where the volume of fluid to be processed is relatively low. These compact units are ideal for small-scale operations or for use in industries where precision and efficiency are paramount. They are often employed in laboratories, small manufacturing units, or in processes where the separation of fine particles is critical. Despite their smaller size, these separators are engineered to deliver high performance, ensuring that even the smallest particulates are effectively removed from the fluid stream. On the other hand, large separators are built to handle substantial volumes of fluid, making them suitable for heavy-duty industrial applications. These robust units are commonly used in large-scale manufacturing plants, oil refineries, and chemical processing facilities where the demand for high-capacity separation is significant. Large separators are designed to withstand harsh operating conditions and are equipped with advanced features to enhance their efficiency and durability. They play a crucial role in ensuring the smooth operation of industrial processes by preventing the accumulation of particulates that could otherwise lead to equipment damage or process inefficiencies. The choice between small and large separators depends largely on the specific requirements of the application, including the volume of fluid to be processed, the nature of the particulates to be removed, and the available space for installation. Both types of separators are integral to the Global Circumfluent Cyclone Separator Market, catering to a wide range of industrial needs and contributing to the overall efficiency and sustainability of industrial operations.

Oil & Gas, Chemical Industrial, Others in the Global Circumfluent Cyclone Separator Market:

The Global Circumfluent Cyclone Separator Market finds extensive application across various industries, with significant usage in the oil and gas, chemical, and other industrial sectors. In the oil and gas industry, these separators are essential for the efficient processing of crude oil and natural gas. They are used to remove particulates and impurities from the extracted fluids, ensuring that the final products meet the required quality standards. The ability of cyclone separators to handle large volumes of fluid and operate under high-pressure conditions makes them particularly suitable for this industry. In the chemical industry, circumfluent cyclone separators are employed to purify chemical products and remove unwanted particles from liquid or gaseous streams. This is crucial for maintaining the purity and quality of chemical products, which is essential for their safe and effective use in various applications. The separators help in reducing contamination and improving the overall efficiency of chemical processes. Beyond these industries, circumfluent cyclone separators are also used in a variety of other applications, including food processing, pharmaceuticals, and environmental management. In food processing, they help in ensuring the purity and safety of food products by removing contaminants. In pharmaceuticals, they are used to maintain the quality of pharmaceutical products by eliminating impurities. In environmental management, these separators play a vital role in air and water purification processes, helping to reduce pollution and protect the environment. The versatility and efficiency of circumfluent cyclone separators make them an indispensable tool in a wide range of industrial applications, contributing to improved product quality, operational efficiency, and environmental sustainability.

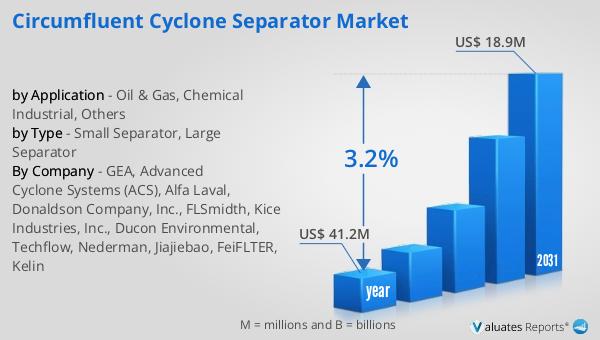

Global Circumfluent Cyclone Separator Market Outlook:

The global market for Circumfluent Cyclone Separator was valued at $41.2 million in 2024, with projections indicating a decrease to $18.9 million by 2031. This shift represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. This market trajectory suggests a dynamic landscape where various factors influence the demand and supply of cyclone separators. The projected decline in market size could be attributed to several factors, including technological advancements leading to more efficient alternatives, changes in industrial practices, or shifts in regulatory requirements. Despite the anticipated reduction in market size, the steady CAGR indicates ongoing demand and potential opportunities for innovation and adaptation within the industry. Companies operating in this market may need to focus on enhancing the efficiency and cost-effectiveness of their products to remain competitive. Additionally, exploring new applications and markets could provide avenues for growth and sustainability. The evolving market conditions underscore the importance of strategic planning and investment in research and development to address the changing needs of industries relying on cyclone separators. As the market adapts to these changes, stakeholders must remain vigilant and proactive in identifying emerging trends and opportunities to ensure continued success in the Global Circumfluent Cyclone Separator Market.

| Report Metric | Details |

| Report Name | Circumfluent Cyclone Separator Market |

| Accounted market size in year | US$ 41.2 million |

| Forecasted market size in 2031 | US$ 18.9 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GEA, Advanced Cyclone Systems (ACS), Alfa Laval, Donaldson Company, Inc., FLSmidth, Kice Industries, Inc., Ducon Environmental, Techflow, Nederman, Jiajiebao, FeiFLTER, Kelin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |