What is Global Canning Processing Equipment Market?

The Global Canning Processing Equipment Market refers to the industry that provides machinery and tools essential for the canning process, which is a method of preserving food by sealing it in airtight containers. This market encompasses a wide range of equipment used in the preparation, processing, and packaging of canned goods. The demand for canning processing equipment is driven by the increasing consumption of canned foods worldwide, as they offer convenience, longer shelf life, and preservation of nutritional value. The market includes various types of machinery such as cooking machines, filling machines, sealing machines, and labeling machines, each playing a crucial role in the canning process. As consumer preferences shift towards ready-to-eat meals and sustainable packaging solutions, the canning processing equipment market is expected to grow, adapting to new technologies and innovations to meet the evolving needs of food manufacturers and consumers. This market is vital for ensuring the efficiency and quality of canned products, which are staples in many households globally.

Cooking Machine, Filling Machine, Sealing Machine, Labeling Machine, Others in the Global Canning Processing Equipment Market:

In the Global Canning Processing Equipment Market, several types of machines play pivotal roles in ensuring the efficiency and quality of canned products. The cooking machine is the first step in the canning process, responsible for preparing the food by cooking it to the desired level. This machine ensures that the food is cooked evenly and thoroughly, which is crucial for both taste and safety. Cooking machines are designed to handle large volumes of food, making them essential for mass production in the canning industry. Next, the filling machine comes into play. This machine is responsible for accurately dispensing the cooked food into cans. Precision is key here, as it ensures that each can contains the right amount of product, minimizing waste and ensuring consistency across batches. Filling machines are equipped with advanced technology to handle different types of food, from liquids to solids, ensuring versatility in the canning process. Following the filling process, the sealing machine takes over. This machine is crucial for ensuring the airtight closure of cans, which is essential for preserving the food's freshness and preventing contamination. Sealing machines are designed to work at high speeds, ensuring that the production line runs smoothly and efficiently. They are equipped with sensors and quality control mechanisms to detect any defects in the sealing process, ensuring that only perfectly sealed cans make it to the market. Once the cans are sealed, the labeling machine is used to apply labels to the cans. This machine ensures that each can is correctly labeled with important information such as the product name, ingredients, nutritional information, and expiration date. Labeling machines are designed to handle different sizes and shapes of cans, ensuring flexibility in the production process. They are equipped with advanced printing technology to ensure that labels are clear and legible, which is crucial for consumer safety and brand recognition. In addition to these core machines, the Global Canning Processing Equipment Market also includes other types of equipment that support the canning process. These may include inspection machines, which ensure that each can meets quality standards before it is shipped to retailers. There are also cleaning machines, which are used to clean the cans before they are filled, ensuring that they are free from contaminants. These machines work together to create a seamless and efficient canning process, ensuring that consumers receive high-quality canned products.

Canned Fruit, Canned Eegetable, Canned Meat and Poultry, Canned Seafood, Others in the Global Canning Processing Equipment Market:

The Global Canning Processing Equipment Market finds its application in various areas, including canned fruit, canned vegetables, canned meat and poultry, canned seafood, and other canned goods. In the realm of canned fruit, the equipment is used to process and preserve a wide variety of fruits, ensuring they retain their flavor, texture, and nutritional value. The cooking machines are used to prepare the fruits, often by blanching or cooking them to the desired consistency. Filling machines then accurately dispense the fruit into cans, while sealing machines ensure that the cans are airtight, preserving the fruit's freshness. Labeling machines provide the necessary information about the fruit, including its origin, nutritional content, and expiration date. In the case of canned vegetables, the equipment is used to process a wide range of vegetables, from peas and carrots to corn and beans. The cooking machines are used to blanch or cook the vegetables, ensuring they are safe for consumption and have the desired texture. Filling machines then dispense the vegetables into cans, ensuring consistency in each can. Sealing machines ensure that the cans are airtight, preserving the vegetables' freshness and nutritional value. Labeling machines provide important information about the vegetables, including their origin, nutritional content, and expiration date. For canned meat and poultry, the equipment is used to process and preserve various types of meat, including beef, chicken, and pork. The cooking machines are used to cook the meat to the desired level, ensuring it is safe for consumption and has the desired flavor and texture. Filling machines then dispense the meat into cans, ensuring consistency in each can. Sealing machines ensure that the cans are airtight, preserving the meat's freshness and preventing contamination. Labeling machines provide important information about the meat, including its origin, nutritional content, and expiration date. In the case of canned seafood, the equipment is used to process and preserve various types of seafood, including fish, shrimp, and crab. The cooking machines are used to cook the seafood to the desired level, ensuring it is safe for consumption and has the desired flavor and texture. Filling machines then dispense the seafood into cans, ensuring consistency in each can. Sealing machines ensure that the cans are airtight, preserving the seafood's freshness and preventing contamination. Labeling machines provide important information about the seafood, including its origin, nutritional content, and expiration date. In addition to these core areas, the Global Canning Processing Equipment Market also finds its application in other areas, including canned soups, sauces, and ready-to-eat meals. The equipment is used to process and preserve these products, ensuring they retain their flavor, texture, and nutritional value. The cooking machines are used to prepare the products, while filling machines dispense them into cans. Sealing machines ensure that the cans are airtight, preserving the products' freshness and preventing contamination. Labeling machines provide important information about the products, including their ingredients, nutritional content, and expiration date.

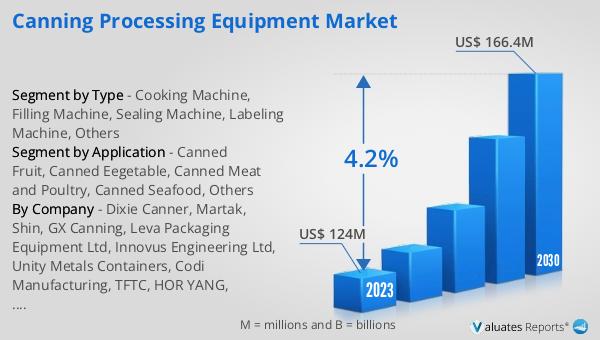

Global Canning Processing Equipment Market Outlook:

The outlook for the Global Canning Processing Equipment Market indicates a promising future. In 2024, the market was valued at approximately $135 million. By 2031, it is anticipated to grow to a revised size of $179 million. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This steady growth can be attributed to several factors, including the increasing demand for canned foods due to their convenience and long shelf life. As consumers continue to seek out ready-to-eat meals and sustainable packaging solutions, the demand for canning processing equipment is expected to rise. The market's growth is also driven by technological advancements in canning equipment, which enhance efficiency and product quality. Manufacturers are investing in research and development to create innovative solutions that meet the evolving needs of food producers and consumers. Additionally, the market is benefiting from the expansion of the food and beverage industry, particularly in emerging markets where the demand for canned goods is on the rise. As the market continues to grow, it presents opportunities for manufacturers to expand their product offerings and reach new customers. Overall, the Global Canning Processing Equipment Market is poised for steady growth, driven by increasing demand for canned foods and advancements in technology.

| Report Metric | Details |

| Report Name | Canning Processing Equipment Market |

| Accounted market size in year | US$ 135 million |

| Forecasted market size in 2031 | US$ 179 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dixie Canner, Martak, Shin, GX Canning, Leva Packaging Equipment Ltd, Innovus Engineering Ltd, Unity Metals Containers, Codi Manufacturing, TFTC, HOR YANG, American Canning Machines, DURFO, Packaging Solution, Cedarstone Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |