What is Global Medical Tube Cutting Machine Market?

The Global Medical Tube Cutting Machine Market is a specialized segment within the broader medical device industry, focusing on machines designed to cut medical tubes with precision and efficiency. These machines are essential in the production of various medical devices and components, such as catheters, IV tubes, and other tubing used in medical applications. The market is driven by the increasing demand for minimally invasive surgical procedures, which require precise and reliable tubing components. Additionally, advancements in medical technology and the growing healthcare sector contribute to the market's expansion. The machines in this market are designed to handle a variety of materials, including plastics, metals, and composites, ensuring versatility and adaptability to different medical applications. Manufacturers in this market are continually innovating to improve the accuracy, speed, and safety of their machines, meeting the stringent regulatory standards of the medical industry. As healthcare systems worldwide continue to evolve and expand, the demand for high-quality medical tube cutting machines is expected to grow, making this market a critical component of the global healthcare infrastructure.

Electric, Pneumatic in the Global Medical Tube Cutting Machine Market:

In the Global Medical Tube Cutting Machine Market, electric and pneumatic machines play pivotal roles, each offering distinct advantages and applications. Electric tube cutting machines are known for their precision and efficiency, making them ideal for high-volume production environments. These machines utilize electric motors to drive the cutting mechanism, providing consistent and accurate cuts. They are often equipped with advanced features such as programmable controls, allowing for customization and automation of the cutting process. This makes electric machines suitable for applications where precision and repeatability are crucial, such as in the production of medical tubing for catheters and IV lines. On the other hand, pneumatic tube cutting machines use compressed air to power the cutting mechanism. These machines are typically more compact and lightweight compared to their electric counterparts, making them suitable for smaller production facilities or applications where space is limited. Pneumatic machines are also known for their speed and ease of maintenance, as they have fewer moving parts and do not require complex electrical systems. This makes them a cost-effective option for manufacturers looking to balance performance with budget constraints. Both electric and pneumatic machines are designed to handle a wide range of materials, including plastics, metals, and composites, ensuring versatility in their applications. The choice between electric and pneumatic machines often depends on the specific needs of the manufacturer, such as production volume, material type, and budget considerations. As the medical device industry continues to grow, the demand for both types of machines is expected to increase, driven by the need for high-quality, reliable tubing components in various medical applications. Manufacturers in this market are continually innovating to improve the performance and capabilities of their machines, ensuring they meet the evolving needs of the healthcare sector.

Silica Gel, Heat Shrink Tubing, PVC, TPE, Emulsion, Others in the Global Medical Tube Cutting Machine Market:

The Global Medical Tube Cutting Machine Market finds extensive usage across various materials, including silica gel, heat shrink tubing, PVC, TPE, emulsion, and others. Each of these materials presents unique challenges and requirements for cutting, making the versatility of cutting machines crucial. Silica gel tubes, for instance, are often used in applications requiring high flexibility and resistance to extreme temperatures. Cutting machines designed for silica gel need to ensure clean cuts without compromising the material's integrity. Heat shrink tubing, commonly used for insulation and protection of electrical connections, requires precise cutting to ensure proper fit and function. Machines used for cutting heat shrink tubing must be capable of handling the material's shrinkage properties, ensuring accurate dimensions post-shrinkage. PVC, a widely used material in medical tubing, demands cutting machines that can handle its rigidity and thickness. PVC tubes are often used in applications such as IV lines and catheters, where precision and smooth edges are critical to prevent patient discomfort or injury. TPE, or thermoplastic elastomers, offer flexibility and durability, making them suitable for a range of medical applications. Cutting machines for TPE must accommodate the material's elasticity, ensuring clean cuts without deformation. Emulsion tubes, used in various medical and laboratory applications, require cutting machines that can handle their unique composition and ensure precise cuts for accurate measurements. Other materials used in medical tubing, such as composites and specialized polymers, also require cutting machines with specific capabilities to ensure high-quality cuts. The ability of cutting machines to handle a diverse range of materials is a key factor driving their demand in the medical device industry. Manufacturers are continually developing and refining their machines to meet the specific needs of different materials, ensuring they provide reliable and efficient solutions for medical tubing production. As the healthcare industry continues to evolve, the demand for versatile and high-performance cutting machines is expected to grow, supporting the production of high-quality medical devices and components.

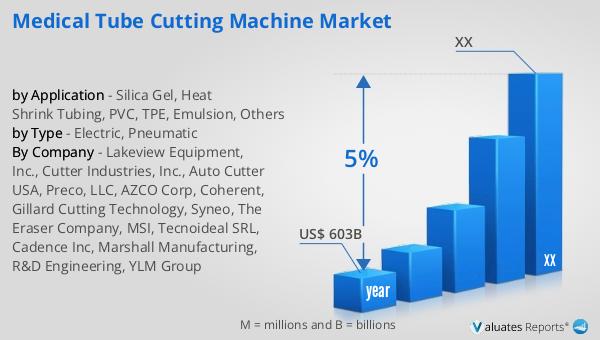

Global Medical Tube Cutting Machine Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, increasing demand for healthcare services, and the rising prevalence of chronic diseases. The medical device industry encompasses a wide range of products, from simple bandages to complex surgical instruments and diagnostic equipment. As healthcare systems worldwide continue to expand and modernize, the demand for innovative and effective medical devices is expected to rise. This growth presents significant opportunities for manufacturers and suppliers in the medical device market, as they strive to meet the evolving needs of healthcare providers and patients. The increasing focus on personalized medicine and minimally invasive procedures is also contributing to the market's expansion, as these approaches require specialized devices and equipment. Additionally, the growing emphasis on healthcare accessibility and affordability is driving demand for cost-effective medical solutions, further fueling market growth. As the global population continues to age and healthcare needs become more complex, the medical device market is poised for sustained growth, offering numerous opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Medical Tube Cutting Machine Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lakeview Equipment, Inc., Cutter Industries, Inc., Auto Cutter USA, Preco, LLC, AZCO Corp, Coherent, Gillard Cutting Technology, Syneo, The Eraser Company, MSI, Tecnoideal SRL, Cadence Inc, Marshall Manufacturing, R&D Engineering, YLM Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |