What is Global Disinfection Dosing Equipment Market?

The Global Disinfection Dosing Equipment Market is a crucial segment within the broader field of sanitation and hygiene, focusing on the precise delivery of disinfectants to ensure effective sterilization and cleanliness. This market encompasses a variety of equipment designed to administer disinfectants in controlled amounts, ensuring optimal efficacy while minimizing waste. These devices are essential in numerous settings, including healthcare facilities, industrial plants, and public spaces, where maintaining high standards of hygiene is paramount. The market is driven by the increasing awareness of the importance of sanitation, especially in the wake of global health challenges. Technological advancements have led to the development of more sophisticated dosing systems that offer enhanced accuracy and efficiency. As industries and governments worldwide prioritize hygiene, the demand for advanced disinfection dosing equipment continues to grow, making it a vital component of modern sanitation strategies. The market's expansion is further supported by regulatory requirements and the need for sustainable and eco-friendly disinfection solutions. Overall, the Global Disinfection Dosing Equipment Market plays a pivotal role in safeguarding public health and ensuring the cleanliness of various environments.

Fully Automatic, Semi Automatic, Manual in the Global Disinfection Dosing Equipment Market:

In the Global Disinfection Dosing Equipment Market, equipment is categorized based on their operational modes: fully automatic, semi-automatic, and manual systems. Fully automatic disinfection dosing equipment represents the pinnacle of technological advancement in this sector. These systems are designed to operate with minimal human intervention, utilizing sensors and advanced algorithms to determine the precise amount of disinfectant needed for a given application. They are particularly beneficial in large-scale operations where consistency and precision are critical. For instance, in a hospital setting, fully automatic systems can ensure that operating rooms and patient areas are consistently disinfected to the highest standards, reducing the risk of infection. These systems often integrate with existing infrastructure, allowing for seamless operation and monitoring. On the other hand, semi-automatic systems offer a balance between automation and manual control. They require some level of human input to initiate or adjust the dosing process but still rely on automated mechanisms to deliver the disinfectant. This type of equipment is ideal for environments where flexibility is needed, such as in smaller clinics or industrial settings where the disinfection requirements may vary. Operators can adjust the settings based on the specific needs of the area being treated, ensuring both efficiency and effectiveness. Manual disinfection dosing equipment, while less technologically advanced, remains a vital component of the market. These systems rely entirely on human operation, requiring personnel to measure and apply the disinfectant manually. They are often used in smaller or more specialized applications where the cost of automated systems cannot be justified. Despite their simplicity, manual systems can be highly effective when used correctly, providing a cost-effective solution for businesses or facilities with limited budgets. Each type of disinfection dosing equipment has its own set of advantages and limitations, making them suitable for different applications and environments. The choice between fully automatic, semi-automatic, and manual systems depends largely on the specific needs of the user, including factors such as budget, scale of operation, and the level of precision required. As technology continues to evolve, we can expect to see further innovations in this market, with systems becoming more efficient, user-friendly, and environmentally sustainable. The ongoing development of smart technologies and IoT integration is likely to enhance the capabilities of disinfection dosing equipment, offering new possibilities for automation and control. Overall, the diversity of equipment available in the Global Disinfection Dosing Equipment Market ensures that there is a solution to meet the varied needs of different industries and applications.

Mechanical Engineering, Automotive, Aeronautics, Marine, Oil And Gas, Chemical Industrial, Medical, Electrical in the Global Disinfection Dosing Equipment Market:

The Global Disinfection Dosing Equipment Market finds applications across a wide range of industries, each with its own unique requirements and challenges. In mechanical engineering, these systems are used to maintain cleanliness and prevent contamination in manufacturing processes. Disinfection dosing equipment ensures that machinery and components are free from harmful microorganisms, which is crucial for maintaining product quality and safety. In the automotive industry, disinfection dosing equipment is employed to sanitize production lines and vehicles, ensuring that both workers and end-users are protected from potential health risks. The aeronautics sector also relies on these systems to maintain high standards of hygiene in aircraft manufacturing and maintenance, where even minor contamination can have significant consequences. In the marine industry, disinfection dosing equipment is used to treat ballast water and other onboard systems, preventing the spread of invasive species and ensuring compliance with international regulations. The oil and gas industry utilizes these systems to maintain the cleanliness of pipelines and equipment, reducing the risk of corrosion and ensuring the safe transport of resources. In the chemical industry, disinfection dosing equipment is essential for maintaining sterile environments in laboratories and production facilities, where contamination can compromise product integrity and safety. The medical field is perhaps one of the most critical areas for disinfection dosing equipment, as it is used to sterilize surgical instruments, patient rooms, and other healthcare environments. These systems help prevent the spread of infections and ensure the safety of both patients and healthcare workers. In the electrical industry, disinfection dosing equipment is used to clean and maintain sensitive electronic components, preventing damage and ensuring optimal performance. Each of these industries has specific requirements for disinfection dosing equipment, and manufacturers must tailor their products to meet these needs. The versatility and adaptability of disinfection dosing equipment make it an invaluable tool across these diverse sectors, contributing to improved safety, efficiency, and compliance with regulatory standards. As industries continue to evolve and face new challenges, the demand for advanced disinfection solutions is likely to grow, driving further innovation and development in the Global Disinfection Dosing Equipment Market.

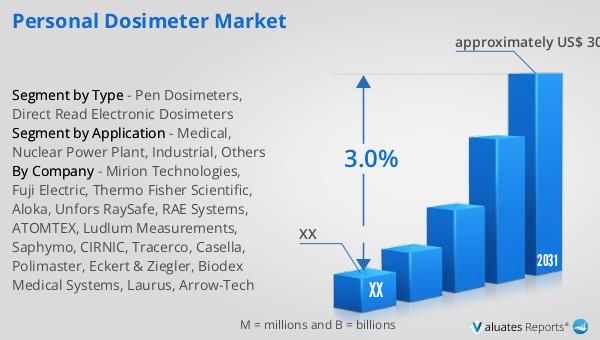

Global Disinfection Dosing Equipment Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years.

| Report Metric | Details |

| Report Name | Disinfection Dosing Equipment Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Evoqua Water Technologies, Ark Electric & Mechanical Co., Ltd, Prodose Limited, Grundfos Management A/S, Hydro Systems, A.O.Smith, Movacolors, JESCO, UGSI Solutions, Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |