What is Global Factory Automation System Market?

The Global Factory Automation System Market refers to the industry focused on the use of technology and control systems to automate manufacturing processes. This market encompasses a wide range of technologies, including robotics, computer software, and control systems, which are used to enhance the efficiency, quality, and flexibility of manufacturing operations. Automation systems are designed to reduce human intervention in production processes, thereby minimizing errors, increasing production speed, and improving overall productivity. The market is driven by the growing demand for high-quality products, the need for cost reduction, and the increasing complexity of manufacturing processes. As industries strive to meet these demands, they are increasingly turning to automation solutions to streamline operations and remain competitive in the global market. The Global Factory Automation System Market is a dynamic and rapidly evolving sector, with advancements in technology continually pushing the boundaries of what is possible in automated manufacturing.

Programmable, Non-programmable in the Global Factory Automation System Market:

In the realm of the Global Factory Automation System Market, automation systems can be broadly categorized into programmable and non-programmable systems. Programmable automation systems are highly flexible and can be reprogrammed to accommodate different tasks or products. These systems are ideal for industries where production requirements frequently change, as they allow for quick adjustments without the need for significant hardware changes. Programmable systems often include technologies such as programmable logic controllers (PLCs), robotics, and computer numerical control (CNC) machines. PLCs are digital computers used for automation of electromechanical processes, such as control of machinery on factory assembly lines. They are highly reliable and can be programmed to perform a wide range of tasks, making them a staple in modern manufacturing environments. Robotics, another key component of programmable systems, are used for tasks that require precision, speed, and endurance beyond human capabilities. They can be programmed to perform complex tasks such as assembly, welding, and painting, significantly enhancing production efficiency and product quality. CNC machines, on the other hand, are used for precise control of machining tools and are essential in industries that require high precision and repeatability. Non-programmable automation systems, in contrast, are designed for specific tasks and lack the flexibility of their programmable counterparts. These systems are typically used in high-volume production environments where the manufacturing process is consistent and does not require frequent changes. Non-programmable systems include fixed automation systems, which are characterized by their high production rates and low unit costs. These systems are ideal for mass production of products with a stable design, as they are optimized for efficiency and cost-effectiveness. While non-programmable systems offer less flexibility, they are highly efficient and reliable, making them a valuable asset in industries where production consistency is paramount. Both programmable and non-programmable systems play a crucial role in the Global Factory Automation System Market, each offering unique advantages that cater to different manufacturing needs. As technology continues to advance, the integration of artificial intelligence and machine learning into these systems is expected to further enhance their capabilities, offering even greater flexibility and efficiency in manufacturing processes.

Oil and Gas, Power and Energy, Chemicals, Food and Drinks, Pharmaceutical, Car, Other in the Global Factory Automation System Market:

The Global Factory Automation System Market finds extensive application across various industries, each leveraging automation to enhance efficiency, reduce costs, and improve product quality. In the oil and gas sector, automation systems are used to monitor and control complex processes, ensuring safety and efficiency in operations. Automation helps in managing the extraction, refining, and distribution processes, reducing the risk of human error and enhancing operational reliability. In the power and energy industry, automation systems are employed to optimize the generation, transmission, and distribution of electricity. These systems enable real-time monitoring and control of power plants, improving efficiency and reducing downtime. The chemical industry benefits from automation through precise control of chemical processes, ensuring consistent product quality and safety. Automation systems help in managing complex chemical reactions, reducing the risk of accidents and improving production efficiency. In the food and drinks industry, automation is used to streamline production processes, ensuring hygiene and consistency in product quality. Automated systems help in tasks such as sorting, packaging, and quality control, reducing labor costs and increasing production speed. The pharmaceutical industry relies on automation for precise control of manufacturing processes, ensuring compliance with stringent regulatory standards. Automation systems help in maintaining product quality and consistency, reducing the risk of contamination and ensuring patient safety. In the automotive industry, automation is used extensively in assembly lines, where robots perform tasks such as welding, painting, and assembly with high precision and speed. This not only improves production efficiency but also enhances product quality and reduces manufacturing costs. Other industries, such as electronics and textiles, also benefit from automation by improving production efficiency and product quality. Overall, the Global Factory Automation System Market plays a vital role in enhancing the competitiveness of various industries by enabling them to produce high-quality products at lower costs and with greater efficiency.

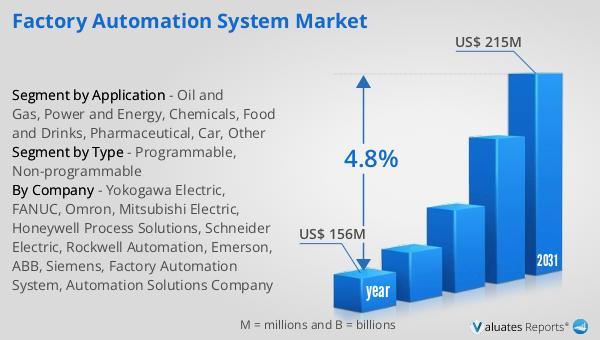

Global Factory Automation System Market Outlook:

The outlook for the Global Factory Automation System Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $156 million. By 2031, it is anticipated to expand to a revised size of around $215 million, reflecting a compound annual growth rate (CAGR) of 4.8% over the forecast period. This growth is driven by the increasing adoption of automation technologies across various industries, as companies seek to enhance efficiency, reduce operational costs, and improve product quality. The demand for factory automation systems is expected to rise as industries continue to face challenges such as labor shortages, rising labor costs, and the need for greater production flexibility. Additionally, advancements in technology, such as the integration of artificial intelligence and machine learning into automation systems, are expected to further drive market growth by offering enhanced capabilities and efficiencies. As industries strive to remain competitive in the global market, the adoption of factory automation systems is likely to become increasingly essential, driving the market's expansion over the coming years. The Global Factory Automation System Market is poised for significant growth, offering numerous opportunities for companies to innovate and enhance their manufacturing processes.

| Report Metric | Details |

| Report Name | Factory Automation System Market |

| Accounted market size in year | US$ 156 million |

| Forecasted market size in 2031 | US$ 215 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Yokogawa Electric, FANUC, Omron, Mitsubishi Electric, Honeywell Process Solutions, Schneider Electric, Rockwell Automation, Emerson, ABB, Siemens, Factory Automation System, Automation Solutions Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |