What is Global Electric Rotary Tablet Press Machine Market?

The Global Electric Rotary Tablet Press Machine Market is a specialized segment within the broader machinery industry, focusing on the production of machines that compress powder into tablets. These machines are essential in various industries, including pharmaceuticals, food, and chemicals, due to their efficiency and precision in tablet production. The market is driven by the increasing demand for tablets in the pharmaceutical industry, where they are used for medication delivery. Additionally, the food industry utilizes these machines to produce dietary supplements and other consumable tablets. The market is characterized by technological advancements that enhance machine efficiency, reduce production costs, and improve tablet quality. Manufacturers are investing in research and development to introduce innovative features such as automated controls and enhanced safety mechanisms. The market is also influenced by regulatory standards that ensure the safety and efficacy of the tablets produced. As industries continue to expand globally, the demand for electric rotary tablet press machines is expected to grow, driven by the need for high-volume, consistent, and reliable tablet production. The market's growth is further supported by the increasing adoption of automation and digitalization in manufacturing processes, which enhances productivity and reduces human error.

Single Rotary Tablet Press, Double-Sided Rotary Tablet Press in the Global Electric Rotary Tablet Press Machine Market:

The Global Electric Rotary Tablet Press Machine Market includes various types of machines, with Single Rotary Tablet Press and Double-Sided Rotary Tablet Press being two prominent categories. The Single Rotary Tablet Press is designed for smaller-scale production and is often used in laboratories or small manufacturing units. It operates with a single set of tooling, meaning it has one die and one punch, which compresses the powder into tablets. This type of machine is ideal for producing small batches of tablets, making it suitable for research and development purposes or for companies that produce a limited range of products. The simplicity of the Single Rotary Tablet Press makes it easy to operate and maintain, which is advantageous for businesses with limited technical expertise. On the other hand, the Double-Sided Rotary Tablet Press is designed for large-scale production and is commonly used in industrial settings. It features two sets of tooling, allowing it to produce tablets on both sides simultaneously. This design significantly increases production capacity, making it suitable for companies that require high-volume tablet production. The Double-Sided Rotary Tablet Press is equipped with advanced features such as automated controls, real-time monitoring, and precision engineering to ensure consistent tablet quality. These machines are often used in the pharmaceutical industry, where large quantities of tablets are required to meet market demand. The choice between Single Rotary and Double-Sided Rotary Tablet Press depends on the specific needs of the manufacturer, including production volume, tablet size, and budget. Both types of machines offer unique advantages and are integral to the efficient production of tablets in various industries. As the demand for tablets continues to rise, manufacturers are investing in advanced rotary tablet press machines to enhance their production capabilities and meet the growing needs of the market.

Medicine, Food, Health Products, Electronic, Chemical in the Global Electric Rotary Tablet Press Machine Market:

The Global Electric Rotary Tablet Press Machine Market finds extensive usage across various sectors, including medicine, food, health products, electronics, and chemicals. In the medical field, these machines are crucial for producing pharmaceutical tablets, which are a common form of medication delivery. The precision and efficiency of rotary tablet press machines ensure that each tablet contains the exact dosage required, which is vital for patient safety and treatment efficacy. In the food industry, these machines are used to produce dietary supplements and vitamins in tablet form. The ability to produce large quantities of tablets quickly and consistently makes rotary tablet press machines ideal for meeting the high demand for health supplements. In the health products sector, these machines are used to manufacture a wide range of products, including herbal supplements and nutraceuticals. The versatility of rotary tablet press machines allows manufacturers to produce tablets in various shapes and sizes, catering to consumer preferences. In the electronics industry, these machines are used to produce tablets that serve as components in electronic devices. The precision and consistency of rotary tablet press machines ensure that each tablet meets the stringent quality standards required in the electronics industry. In the chemical industry, these machines are used to compress chemical powders into tablets for various applications, including laboratory testing and industrial processes. The ability to produce tablets with specific properties, such as hardness and dissolution rate, makes rotary tablet press machines valuable tools in the chemical industry. Overall, the Global Electric Rotary Tablet Press Machine Market plays a vital role in various industries, providing the technology needed to produce high-quality tablets efficiently and consistently.

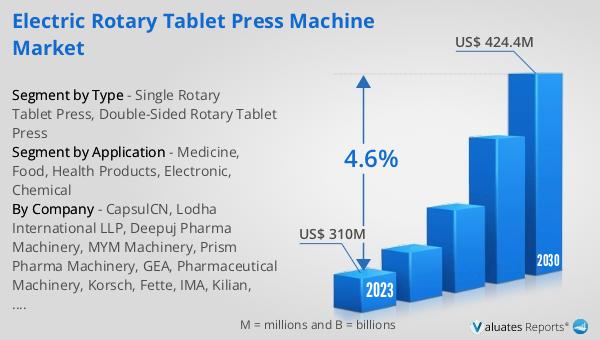

Global Electric Rotary Tablet Press Machine Market Outlook:

In 2024, the global market for Electric Rotary Tablet Press Machines was valued at approximately $337 million. This market is anticipated to expand, reaching an estimated size of $460 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. The market's expansion is driven by several factors, including the increasing demand for tablets in various industries such as pharmaceuticals, food, and chemicals. As these industries continue to grow, the need for efficient and reliable tablet production machinery becomes more critical. The market is also influenced by technological advancements that enhance machine performance, reduce production costs, and improve tablet quality. Manufacturers are focusing on developing innovative features such as automated controls and enhanced safety mechanisms to meet the evolving needs of their customers. Additionally, the market is shaped by regulatory standards that ensure the safety and efficacy of the tablets produced. As industries continue to expand globally, the demand for electric rotary tablet press machines is expected to grow, driven by the need for high-volume, consistent, and reliable tablet production. The market's growth is further supported by the increasing adoption of automation and digitalization in manufacturing processes, which enhances productivity and reduces human error.

| Report Metric | Details |

| Report Name | Electric Rotary Tablet Press Machine Market |

| Accounted market size in year | US$ 337 million |

| Forecasted market size in 2031 | US$ 460 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CapsulCN, Lodha International LLP, Deepuj Pharma Machinery, MYM Machinery, Prism Pharma Machinery, GEA, Pharmaceutical Machinery, Korsch, Fette, IMA, Kilian, Stokes, Manesty, Kikusui, ACG Worldwide, Fluidpack, Jinhe Mixer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |