What is Global Electromechanical Toggle Switch Market?

The Global Electromechanical Toggle Switch Market is a dynamic and essential segment within the broader electronics industry. Electromechanical toggle switches are devices used to control the flow of electricity in a circuit by manually flipping a lever or handle. These switches are widely used across various industries due to their reliability, durability, and ease of use. The market for these switches is driven by the increasing demand for efficient and reliable electrical components in industrial, automotive, consumer electronics, and other sectors. As technology advances, the need for more sophisticated and versatile toggle switches continues to grow. These switches come in various types, including illuminated and non-illuminated versions, catering to different application needs. The global market is characterized by a diverse range of manufacturers and suppliers, each offering unique products to meet the specific requirements of their customers. With the ongoing development of new technologies and the expansion of industries that rely on these switches, the Global Electromechanical Toggle Switch Market is poised for continued growth and innovation.

Illuminated Toggle Switch, Non-Illuminated Toggle Switch in the Global Electromechanical Toggle Switch Market:

Illuminated toggle switches are a significant component of the Global Electromechanical Toggle Switch Market. These switches are designed with built-in lighting, which provides visual feedback to the user, indicating the switch's status. This feature is particularly useful in low-light environments or situations where quick identification of the switch's position is crucial. Illuminated toggle switches are commonly used in automotive dashboards, aircraft cockpits, and industrial control panels, where visibility and accessibility are paramount. The illumination can be achieved through various means, such as LED lights, which are energy-efficient and long-lasting. These switches are available in different colors and styles, allowing for customization to suit specific design requirements. On the other hand, non-illuminated toggle switches are more traditional and are used in applications where visual feedback is not necessary. These switches are often found in household appliances, basic electronic devices, and simple industrial machinery. Despite lacking illumination, non-illuminated toggle switches are valued for their simplicity, cost-effectiveness, and reliability. Both types of switches play a crucial role in the market, catering to a wide range of applications and industries. The choice between illuminated and non-illuminated toggle switches depends on the specific needs of the application, such as the environment in which the switch will be used, the importance of visual feedback, and budget considerations. As the demand for more advanced and user-friendly electronic components grows, manufacturers continue to innovate and improve the design and functionality of both illuminated and non-illuminated toggle switches. This ongoing development ensures that these switches remain relevant and valuable in an ever-evolving market.

Industrial Products, Consumer Electronics, Automotive, Medical, Aerospace, Telecoms, Others in the Global Electromechanical Toggle Switch Market:

The Global Electromechanical Toggle Switch Market finds extensive usage across various sectors, each with its unique requirements and applications. In the industrial products sector, toggle switches are used in machinery and equipment to control operations and ensure safety. These switches are essential for starting and stopping machines, adjusting settings, and providing emergency shut-off capabilities. In consumer electronics, toggle switches are found in devices such as televisions, audio equipment, and home appliances, where they offer a simple and effective means of controlling power and functions. The automotive industry relies heavily on toggle switches for vehicle control systems, including lighting, climate control, and infotainment systems. These switches provide drivers with easy access to essential functions, enhancing the overall driving experience. In the medical field, toggle switches are used in medical devices and equipment, where precision and reliability are critical. These switches help control various functions, such as power supply, mode selection, and device operation, ensuring that medical professionals can deliver accurate and efficient care. The aerospace industry also utilizes toggle switches in aircraft control panels, where they are used to manage systems such as lighting, communication, and navigation. These switches are designed to withstand harsh conditions and provide reliable performance in critical situations. In the telecom sector, toggle switches are used in network equipment and communication devices, where they help manage connections and signal flow. Other industries, such as marine, military, and transportation, also benefit from the versatility and reliability of toggle switches. The widespread use of these switches across different sectors highlights their importance in modern technology and their role in enhancing the functionality and safety of various systems and devices.

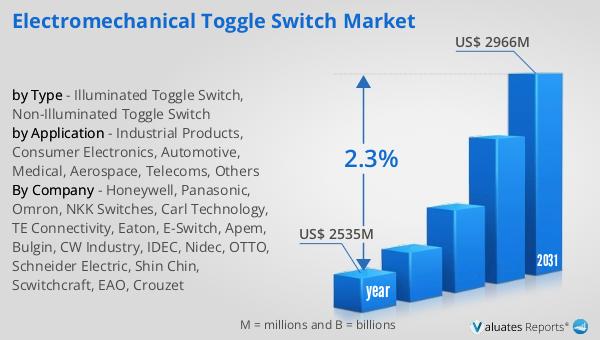

Global Electromechanical Toggle Switch Market Outlook:

The global market for Electromechanical Toggle Switches was valued at approximately $2,535 million in 2024. It is anticipated to grow steadily, reaching an estimated size of $2,966 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.3% over the forecast period. This steady increase in market size reflects the ongoing demand for reliable and efficient toggle switches across various industries. The market's expansion is driven by the continuous development of new technologies and the increasing need for advanced electronic components in sectors such as automotive, industrial, consumer electronics, and more. As industries evolve and new applications for toggle switches emerge, the market is expected to continue its upward trajectory. The projected growth also underscores the importance of innovation and adaptation in the toggle switch market, as manufacturers strive to meet the changing needs of their customers and stay competitive in a dynamic global landscape.

| Report Metric | Details |

| Report Name | Electromechanical Toggle Switch Market |

| Accounted market size in year | US$ 2535 million |

| Forecasted market size in 2031 | US$ 2966 million |

| CAGR | 2.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Honeywell, Panasonic, Omron, NKK Switches, Carl Technology, TE Connectivity, Eaton, E-Switch, Apem, Bulgin, CW Industry, IDEC, Nidec, OTTO, Schneider Electric, Shin Chin, Scwitchcraft, EAO, Crouzet |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |