What is Global Solid Paddle Mixer Market?

The Global Solid Paddle Mixer Market is a specialized segment within the industrial equipment sector, focusing on devices designed to mix solid materials efficiently. These mixers are essential in various industries, including chemical, food and beverage, pharmaceuticals, and more, where the uniform blending of solid particles is crucial. Solid paddle mixers are characterized by their robust construction and ability to handle a wide range of materials, from powders to granules. They operate by using paddles that rotate within a stationary drum, ensuring thorough mixing of the contents. The market for these mixers is driven by the increasing demand for efficient and reliable mixing solutions across different sectors. As industries continue to evolve and require more sophisticated processing equipment, the demand for solid paddle mixers is expected to grow. This growth is further fueled by technological advancements that enhance the performance and efficiency of these mixers, making them more appealing to a broader range of applications. The global solid paddle mixer market is thus a dynamic and essential component of the industrial machinery landscape, catering to the diverse needs of modern manufacturing and processing industries.

Horizontal, Vertical in the Global Solid Paddle Mixer Market:

In the Global Solid Paddle Mixer Market, two primary configurations are prevalent: horizontal and vertical mixers. Each type has its unique advantages and applications, catering to different industrial needs. Horizontal solid paddle mixers are widely used due to their efficient mixing capabilities and ease of integration into existing production lines. These mixers consist of a horizontal drum with rotating paddles that ensure thorough mixing of materials. They are particularly suitable for processes that require continuous mixing and are often used in large-scale production environments. The design of horizontal mixers allows for easy loading and unloading of materials, making them ideal for industries with high throughput requirements. Additionally, they are known for their versatility, as they can handle a wide range of materials, from fine powders to coarse granules. On the other hand, vertical solid paddle mixers are designed with a vertical drum and rotating paddles. These mixers are typically used in applications where space is limited, as their vertical design requires less floor space compared to horizontal mixers. Vertical mixers are also known for their ability to handle delicate materials that require gentle mixing to prevent damage. This makes them suitable for industries such as pharmaceuticals and food processing, where maintaining the integrity of the product is crucial. Furthermore, vertical mixers are often preferred for batch processing, where precise control over the mixing process is required. Both horizontal and vertical solid paddle mixers play a vital role in the global market, offering solutions tailored to the specific needs of various industries. As the demand for efficient and reliable mixing equipment continues to rise, manufacturers are focusing on developing innovative designs that enhance the performance and versatility of these mixers. This includes the incorporation of advanced technologies such as automation and digital controls, which improve the precision and efficiency of the mixing process. The choice between horizontal and vertical mixers ultimately depends on the specific requirements of the application, including factors such as space availability, material characteristics, and production volume. By understanding the unique features and benefits of each type, industries can make informed decisions that optimize their mixing processes and contribute to overall operational efficiency.

Chemical Industry, Mining, Food and Beverages, Pharmaceutical, Paint and Coatings, Others in the Global Solid Paddle Mixer Market:

The Global Solid Paddle Mixer Market finds extensive usage across various industries, each with its unique requirements and challenges. In the chemical industry, solid paddle mixers are essential for blending raw materials and additives to produce a wide range of chemical products. These mixers ensure uniform distribution of components, which is critical for maintaining product quality and consistency. The robust construction of solid paddle mixers allows them to handle abrasive and corrosive materials commonly found in chemical processing. In the mining industry, these mixers are used for processing ores and minerals, where efficient mixing is crucial for optimizing extraction and refining processes. The ability of solid paddle mixers to handle large volumes of material makes them ideal for mining operations that require high throughput. In the food and beverage industry, solid paddle mixers are used for mixing ingredients to produce a variety of food products, from baked goods to confectionery. The gentle mixing action of these mixers helps preserve the texture and quality of the ingredients, ensuring a high-quality end product. In the pharmaceutical industry, solid paddle mixers are used for blending active pharmaceutical ingredients with excipients to produce tablets and capsules. The precise control offered by these mixers is essential for ensuring the uniform distribution of active ingredients, which is critical for the efficacy and safety of pharmaceutical products. In the paint and coatings industry, solid paddle mixers are used for blending pigments, resins, and other additives to produce a wide range of paint products. The ability of these mixers to handle viscous materials and ensure uniform dispersion of components is crucial for achieving the desired color and finish. Beyond these industries, solid paddle mixers are also used in various other applications, including the production of plastics, ceramics, and construction materials. The versatility and reliability of solid paddle mixers make them an indispensable tool in modern manufacturing and processing, catering to the diverse needs of industries worldwide.

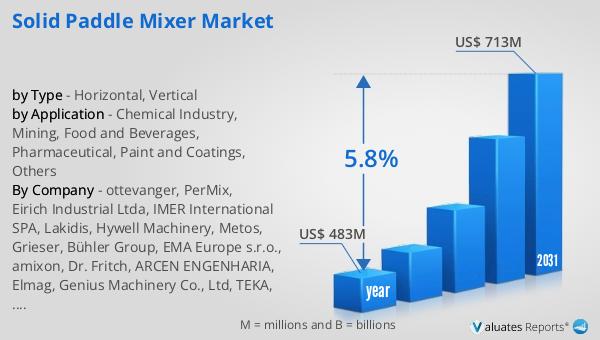

Global Solid Paddle Mixer Market Outlook:

The global market for solid paddle mixers was valued at approximately $483 million in 2024, reflecting its significant role in various industrial sectors. This market is projected to grow steadily, reaching an estimated size of $713 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.8% over the forecast period. The increasing demand for efficient and reliable mixing solutions across industries is a key driver of this growth. As industries continue to evolve and require more sophisticated processing equipment, the need for advanced mixing technologies is expected to rise. Solid paddle mixers, with their robust construction and versatile applications, are well-positioned to meet this demand. The market's expansion is also supported by technological advancements that enhance the performance and efficiency of these mixers, making them more appealing to a broader range of applications. As a result, the global solid paddle mixer market is poised for continued growth, driven by the increasing need for high-quality mixing solutions in various industries. This growth not only reflects the importance of solid paddle mixers in modern manufacturing and processing but also highlights the ongoing innovation and development within the industry.

| Report Metric | Details |

| Report Name | Solid Paddle Mixer Market |

| Accounted market size in year | US$ 483 million |

| Forecasted market size in 2031 | US$ 713 million |

| CAGR | 5.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ottevanger, PerMix, Eirich Industrial Ltda, IMER International SPA, Lakidis, Hywell Machinery, Metos, Grieser, Bühler Group, EMA Europe s.r.o., amixon, Dr. Fritch, ARCEN ENGENHARIA, Elmag, Genius Machinery Co., Ltd, TEKA, TTC Mühendislik, SANGATI BERGA, SPARKY Power Tools, MODELCO, APEC, Lancaster Products, Jaygo, Inc., Charles Ross & Son Company, Eirich Machines, Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |