What is Global Die Casting Machine for Automobile Market?

The Global Die Casting Machine for Automobile Market is a specialized segment within the broader automotive manufacturing industry, focusing on the production of metal components through the die casting process. Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. This method is widely used in the automotive industry due to its ability to produce complex shapes with high precision and excellent surface finish. The global market for die casting machines is driven by the increasing demand for lightweight and durable components in automobiles, which help improve fuel efficiency and reduce emissions. As the automotive industry continues to evolve, with a growing emphasis on electric vehicles and advanced technologies, the demand for die casting machines is expected to rise. These machines are essential for producing a wide range of automotive parts, including engine blocks, transmission cases, and structural components. The market is characterized by technological advancements, with manufacturers focusing on developing more efficient and environmentally friendly machines. Additionally, the shift towards electric vehicles is expected to create new opportunities for the die casting machine market, as these vehicles require different types of components compared to traditional fuel-powered cars. Overall, the Global Die Casting Machine for Automobile Market plays a crucial role in the automotive manufacturing process, contributing to the production of high-quality and reliable vehicles.

Hot Chamber Die Casting Machine, Cold Chamber Die Casting Machine in the Global Die Casting Machine for Automobile Market:

In the realm of die casting machines, two primary types are prevalent: Hot Chamber Die Casting Machines and Cold Chamber Die Casting Machines. Each type serves distinct purposes and is suited for different materials and applications within the Global Die Casting Machine for Automobile Market. Hot Chamber Die Casting Machines are typically used for metals with low melting points, such as zinc, magnesium, and lead. These machines have an integrated furnace that keeps the metal in a molten state, allowing for rapid cycling and high production rates. The process involves the injection of molten metal into the die cavity using a plunger, which is submerged in the molten metal. This method is highly efficient for producing small to medium-sized components with intricate designs and is favored for its speed and cost-effectiveness. However, it is not suitable for metals with high melting points, as the high temperatures can damage the machine components. On the other hand, Cold Chamber Die Casting Machines are designed for metals with higher melting points, such as aluminum and copper. In this process, the molten metal is ladled into the injection chamber from an external furnace, and a hydraulic piston forces the metal into the die cavity. This method is slower compared to hot chamber die casting but is essential for materials that cannot be used in hot chamber machines due to their high melting temperatures. Cold chamber die casting is ideal for producing larger components and is widely used in the automotive industry for parts that require high strength and durability, such as engine blocks and transmission housings. The choice between hot and cold chamber die casting machines depends on the specific requirements of the component being produced, including the type of metal, the size and complexity of the part, and the desired production speed. Both types of die casting machines have their advantages and limitations, and manufacturers often choose the appropriate machine based on the specific needs of their production process. Technological advancements have led to the development of more efficient and precise machines, with features such as automated controls, improved cooling systems, and enhanced safety measures. These innovations have contributed to the growth of the Global Die Casting Machine for Automobile Market, as manufacturers seek to improve the quality and efficiency of their production processes. Additionally, the increasing demand for lightweight and fuel-efficient vehicles has driven the need for advanced die casting technologies that can produce high-quality components with minimal waste. As the automotive industry continues to evolve, the role of die casting machines is expected to become even more critical, with a growing emphasis on sustainability and environmental responsibility. Overall, the choice between hot and cold chamber die casting machines is a crucial decision for manufacturers, as it impacts the quality, cost, and efficiency of the production process.

Fuel Car, Electric Vehicle in the Global Die Casting Machine for Automobile Market:

The usage of Global Die Casting Machines in the automobile market is pivotal, particularly in the production of components for both fuel cars and electric vehicles. In traditional fuel cars, die casting machines are extensively used to manufacture a variety of parts that are essential for the vehicle's operation and performance. These include engine blocks, transmission cases, and various structural components that require high strength and durability. The precision and efficiency of die casting make it an ideal choice for producing complex shapes with tight tolerances, which are crucial for the performance and reliability of fuel-powered vehicles. Additionally, the ability to produce lightweight components through die casting contributes to improved fuel efficiency and reduced emissions, aligning with the industry's goals of sustainability and environmental responsibility. In the context of electric vehicles (EVs), the role of die casting machines is equally significant, albeit with some differences in the types of components produced. Electric vehicles require a different set of components compared to traditional fuel cars, with a greater emphasis on lightweight materials and efficient thermal management. Die casting machines are used to produce parts such as battery housings, motor casings, and structural components that support the vehicle's electric powertrain. The lightweight and high-strength properties of die-cast components are particularly beneficial for EVs, as they help to maximize the vehicle's range and performance. Furthermore, the precision and consistency of die casting ensure that the components meet the stringent quality standards required for electric vehicles. The transition towards electric vehicles presents new opportunities and challenges for the Global Die Casting Machine for Automobile Market. As automakers invest in the development of new EV models, the demand for advanced die casting technologies is expected to increase. Manufacturers are focusing on developing machines that can handle the specific requirements of EV components, such as improved thermal management and the ability to work with new materials. Additionally, the shift towards electric vehicles is driving innovation in die casting processes, with a focus on reducing energy consumption and minimizing waste. This aligns with the broader industry trends of sustainability and environmental responsibility, as manufacturers seek to reduce their carbon footprint and improve the efficiency of their production processes. Overall, the usage of Global Die Casting Machines in the automobile market is integral to the production of both fuel cars and electric vehicles. The ability to produce high-quality, lightweight, and durable components through die casting is essential for meeting the demands of the modern automotive industry. As the industry continues to evolve, with a growing emphasis on electric vehicles and sustainable manufacturing practices, the role of die casting machines is expected to become even more critical. Manufacturers will need to adapt to the changing landscape, investing in new technologies and processes to meet the needs of the next generation of vehicles.

Global Die Casting Machine for Automobile Market Outlook:

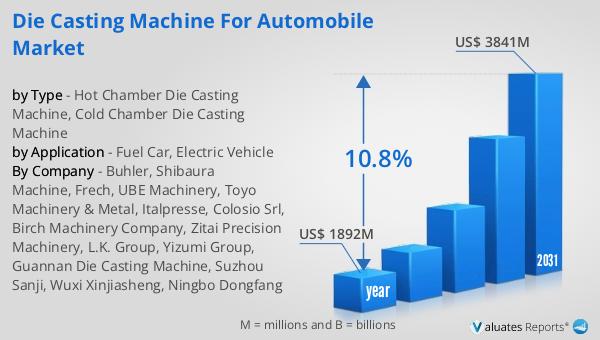

The outlook for the Global Die Casting Machine for Automobile Market is promising, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately US$ 1892 million, reflecting the strong demand for die casting machines in the automotive industry. This demand is driven by the need for lightweight and durable components that enhance vehicle performance and fuel efficiency. As the industry continues to evolve, with a growing emphasis on electric vehicles and advanced manufacturing technologies, the market for die casting machines is expected to expand significantly. By 2031, the market is projected to reach a revised size of US$ 3841 million, representing a compound annual growth rate (CAGR) of 10.8% during the forecast period. This growth is indicative of the increasing importance of die casting machines in the production of automotive components, as manufacturers seek to improve the quality and efficiency of their production processes. The shift towards electric vehicles is also expected to contribute to the market's expansion, as these vehicles require different types of components compared to traditional fuel-powered cars. Additionally, technological advancements in die casting machines, such as improved automation and enhanced precision, are expected to drive further growth in the market. These innovations enable manufacturers to produce high-quality components with minimal waste, aligning with the industry's goals of sustainability and environmental responsibility. Overall, the outlook for the Global Die Casting Machine for Automobile Market is positive, with significant opportunities for growth and innovation. As the automotive industry continues to evolve, the demand for advanced die casting technologies is expected to increase, driving the market's expansion over the coming years. Manufacturers will need to adapt to the changing landscape, investing in new technologies and processes to meet the needs of the next generation of vehicles.

| Report Metric | Details |

| Report Name | Die Casting Machine for Automobile Market |

| Accounted market size in year | US$ 1892 million |

| Forecasted market size in 2031 | US$ 3841 million |

| CAGR | 10.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Buhler, Shibaura Machine, Frech, UBE Machinery, Toyo Machinery & Metal, Italpresse, Colosio Srl, Birch Machinery Company, Zitai Precision Machinery, L.K. Group, Yizumi Group, Guannan Die Casting Machine, Suzhou Sanji, Wuxi Xinjiasheng, Ningbo Dongfang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |