What is Global High Performance Planetary Gearboxes Market?

The Global High Performance Planetary Gearboxes Market is a specialized segment within the broader mechanical and industrial engineering industry. These gearboxes are renowned for their efficiency, precision, and ability to handle high torque loads, making them indispensable in various high-demand applications. Unlike traditional gear systems, planetary gearboxes consist of a central sun gear, multiple planet gears, and an outer ring gear, all of which work in harmony to distribute power evenly. This unique configuration allows for compact design and high power density, which are crucial in applications where space and weight are at a premium. The market for these gearboxes is driven by the increasing demand for automation and the need for efficient power transmission solutions across various industries. As industries continue to evolve and seek more efficient machinery, the demand for high-performance planetary gearboxes is expected to grow, driven by advancements in technology and the need for more sustainable and efficient mechanical solutions. These gearboxes are not only pivotal in enhancing the performance of machinery but also play a crucial role in reducing energy consumption and operational costs, making them a vital component in modern industrial applications.

In Line Planetary Gearboxes, Right-Angle Planetary Gearboxes in the Global High Performance Planetary Gearboxes Market:

In the realm of high-performance planetary gearboxes, two primary types stand out: In-Line Planetary Gearboxes and Right-Angle Planetary Gearboxes. In-Line Planetary Gearboxes are designed with the input and output shafts aligned, making them ideal for applications where space is limited and a compact design is essential. These gearboxes are known for their high efficiency and ability to handle high torque loads, making them suitable for a wide range of applications, from robotics to industrial machinery. Their design allows for smooth and precise motion control, which is crucial in applications requiring high precision and reliability. On the other hand, Right-Angle Planetary Gearboxes are designed with the input and output shafts at a 90-degree angle, providing flexibility in design and installation. This configuration is particularly beneficial in applications where space constraints or specific design requirements necessitate a right-angle configuration. Right-Angle Planetary Gearboxes are often used in applications such as conveyor systems, packaging machinery, and other industrial equipment where space and design flexibility are critical. Both types of gearboxes offer unique advantages and are chosen based on the specific requirements of the application, including factors such as space, torque, efficiency, and precision. The choice between In-Line and Right-Angle Planetary Gearboxes often depends on the specific needs of the application, with considerations such as space constraints, torque requirements, and the need for precise motion control playing a crucial role in the decision-making process. As industries continue to evolve and demand more efficient and reliable power transmission solutions, the demand for both In-Line and Right-Angle Planetary Gearboxes is expected to grow, driven by advancements in technology and the need for more sustainable and efficient mechanical solutions. These gearboxes are not only pivotal in enhancing the performance of machinery but also play a crucial role in reducing energy consumption and operational costs, making them a vital component in modern industrial applications.

Robotics, Food Processing Machinery, Packaging Machinery, Textile, Printing Machinery, Semiconductor Equipment, Machine Tools, Aerospace, Medical Devices, Engineering Machinery, Others in the Global High Performance Planetary Gearboxes Market:

The Global High Performance Planetary Gearboxes Market finds extensive usage across a variety of industries, each with its unique set of requirements and challenges. In the field of robotics, these gearboxes are essential for providing the precision and control needed for complex robotic movements. Their ability to handle high torque loads and deliver smooth, precise motion makes them ideal for robotic arms and automated systems. In the food processing industry, planetary gearboxes are used in machinery that requires high efficiency and reliability, such as mixers and conveyors. Their compact design and high power density make them suitable for applications where space is limited, and hygiene standards are critical. Packaging machinery also benefits from the use of high-performance planetary gearboxes, as they provide the speed and precision needed for efficient packaging processes. In the textile industry, these gearboxes are used in machinery that requires precise control and high efficiency, such as looms and knitting machines. Printing machinery also relies on planetary gearboxes for their ability to deliver consistent and precise motion, which is crucial for high-quality printing. In the semiconductor industry, these gearboxes are used in equipment that requires high precision and reliability, such as wafer handling systems. Machine tools also benefit from the use of planetary gearboxes, as they provide the precision and control needed for complex machining processes. In the aerospace industry, these gearboxes are used in applications that require high reliability and efficiency, such as aircraft control systems. Medical devices also rely on planetary gearboxes for their ability to deliver precise and reliable motion, which is crucial for applications such as surgical robots and diagnostic equipment. Engineering machinery, such as construction equipment and industrial robots, also benefits from the use of high-performance planetary gearboxes, as they provide the power and precision needed for demanding applications. Other industries, such as renewable energy and automotive, also rely on planetary gearboxes for their ability to deliver efficient and reliable power transmission solutions. As industries continue to evolve and demand more efficient and reliable machinery, the demand for high-performance planetary gearboxes is expected to grow, driven by advancements in technology and the need for more sustainable and efficient mechanical solutions.

Global High Performance Planetary Gearboxes Market Outlook:

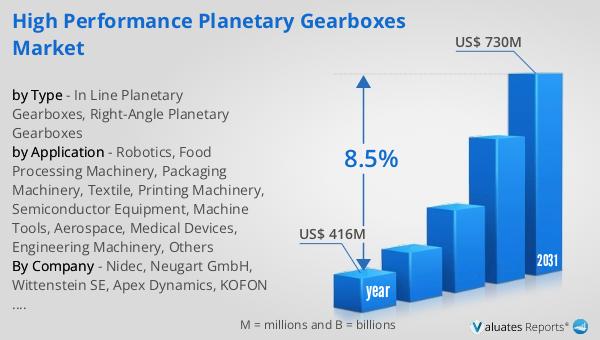

The global market for High Performance Planetary Gearboxes was valued at $416 million in 2024, and projections indicate a significant growth trajectory, with expectations to reach approximately $730 million by 2031. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 8.5% over the forecast period. This upward trend underscores the increasing demand for efficient and reliable power transmission solutions across various industries. The growth of this market is driven by several factors, including the rising demand for automation, the need for energy-efficient solutions, and advancements in technology that enhance the performance and reliability of these gearboxes. As industries continue to evolve and seek more efficient and sustainable solutions, the demand for high-performance planetary gearboxes is expected to grow. This growth is not only a testament to the importance of these gearboxes in modern industrial applications but also highlights the ongoing need for innovation and advancement in the field of mechanical engineering. As the market continues to expand, manufacturers and suppliers will need to focus on developing new and innovative solutions to meet the evolving needs of their customers and stay competitive in this dynamic and rapidly changing market.

| Report Metric | Details |

| Report Name | High Performance Planetary Gearboxes Market |

| Accounted market size in year | US$ 416 million |

| Forecasted market size in 2031 | US$ 730 million |

| CAGR | 8.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nidec, Neugart GmbH, Wittenstein SE, Apex Dynamics, KOFON Motion Group, LI-MING Machinery, Newstart, Rouist, STOBER, Harmonic Drive Systems, Ningbo ZhongDa Leader, ZF, Sesame Motor, Sumitomo, PIN HONG TECHNOLOGY, Shanghai Lian Heng Precision Machinery, Shenzhen Zhikong Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |