What is Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market?

The Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market is a specialized segment within the broader industrial valves market, focusing on the production and distribution of valves that meet stringent hygiene and sterility standards. These valves are crucial in industries where contamination control is paramount, such as pharmaceuticals and biotechnology. The market encompasses a variety of valve types, each designed to ensure that the flow of liquids or gases remains uncontaminated and sterile throughout the production process. These valves are engineered to withstand rigorous cleaning and sterilization processes, often involving high temperatures and aggressive chemicals, without compromising their integrity or performance. The demand for these valves is driven by the increasing need for safe and efficient manufacturing processes in the pharmaceutical and biotech sectors, where even the slightest contamination can lead to significant product loss or health risks. As these industries continue to grow and innovate, the market for hygienic and aseptic valves is expected to expand, driven by advancements in valve technology and the ongoing emphasis on quality and safety in production environments.

Hygienic Single Seat Valves, Hygienic Double Seat Valves, Hygienic Butterfly Valves, Hygienic Control Valves, Hygienic Diaphragm Valves, Aseptic Valves in the Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market:

Hygienic Single Seat Valves are designed for applications requiring a high level of cleanliness and sterility. These valves are typically used in processes where the flow of liquids needs to be controlled with precision, and they are easy to clean and maintain. Hygienic Double Seat Valves, on the other hand, are used in applications where two different fluids need to be handled simultaneously without mixing. They are equipped with two seats that provide a secure seal, preventing cross-contamination. Hygienic Butterfly Valves are known for their simple design and ease of operation. They are often used in applications where quick shut-off is required, and their compact size makes them ideal for installations with limited space. Hygienic Control Valves are used to regulate the flow of fluids in a process, ensuring that the desired flow rate is maintained. These valves are essential in processes where precise control over fluid dynamics is necessary. Hygienic Diaphragm Valves are designed for applications where the valve needs to be frequently cleaned or sterilized. They feature a flexible diaphragm that acts as a barrier between the fluid and the valve body, preventing contamination. Aseptic Valves are specifically designed for applications where sterility is critical. They are used in processes where the risk of contamination must be minimized, such as in the production of sterile pharmaceuticals or biotechnology products. These valves are engineered to withstand rigorous cleaning and sterilization processes, ensuring that they remain free of contaminants. The Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market is characterized by a wide range of valve types, each designed to meet the specific needs of different applications. As the demand for safe and efficient manufacturing processes continues to grow, the market for these valves is expected to expand, driven by advancements in valve technology and the ongoing emphasis on quality and safety in production environments.

Pharmaceuticals, Biotechnology in the Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market:

In the pharmaceutical industry, the use of Global Hygienic and Aseptic Valves is critical to ensuring the safety and efficacy of drug products. These valves are used in various stages of drug manufacturing, from the initial mixing of raw materials to the final packaging of the finished product. They help maintain a sterile environment, preventing contamination that could compromise the quality of the drugs. In biotechnology, these valves are used in the production of biologics, which are complex molecules derived from living cells. The production of biologics requires a high level of precision and control, as even minor contamination can affect the efficacy of the final product. Hygienic and aseptic valves play a crucial role in maintaining the integrity of the production process, ensuring that the final product meets the required safety and quality standards. The use of these valves is also essential in the production of vaccines, where sterility is of utmost importance. In both pharmaceuticals and biotechnology, the demand for hygienic and aseptic valves is driven by the need for safe and efficient manufacturing processes. As these industries continue to grow and innovate, the market for these valves is expected to expand, driven by advancements in valve technology and the ongoing emphasis on quality and safety in production environments.

Global Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market Outlook:

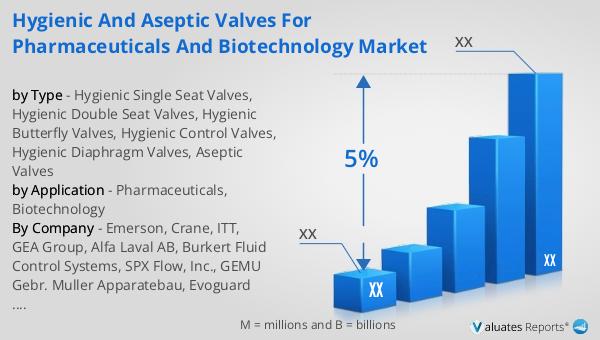

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth reflects the increasing demand for pharmaceutical products worldwide, driven by factors such as an aging population, the rise of chronic diseases, and advancements in drug development. In comparison, the chemical drug market has shown a steady increase, growing from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the chemical drug market highlights the ongoing demand for traditional pharmaceuticals, even as the industry shifts towards more complex biologics and personalized medicine. The expansion of these markets underscores the importance of maintaining high standards of quality and safety in drug manufacturing, which in turn drives the demand for hygienic and aseptic valves. These valves are essential components in the production processes of both chemical and biological drugs, ensuring that the final products are free from contamination and meet the stringent regulatory requirements of the pharmaceutical industry. As the global pharmaceutical market continues to grow, the demand for hygienic and aseptic valves is expected to increase, supporting the industry's commitment to delivering safe and effective medications to patients worldwide.

| Report Metric | Details |

| Report Name | Hygienic and Aseptic Valves for Pharmaceuticals and Biotechnology Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Emerson, Crane, ITT, GEA Group, Alfa Laval AB, Burkert Fluid Control Systems, SPX Flow, Inc., GEMU Gebr. Muller Apparatebau, Evoguard GmbH (Krones), Keiselmann Fluid Process Group, Bardiani Valvole SpA, Gebr. Rieger GmbH & Co. KG, M&S Armaturen GmbH, Armaturenwerk Hotensleben GmbH, Zhejiang Yuanan Liquid Equipment, INOXPA S.A. (Interpump Group), Cipriani Harrison Valves Corporation, Nocado GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |