What is Global Industry Robot Precision Reduction Gears Market?

The Global Industry Robot Precision Reduction Gears Market is a specialized segment within the broader robotics industry, focusing on the production and distribution of precision reduction gears used in industrial robots. These gears are crucial components that enhance the performance and efficiency of robots by providing precise motion control and torque management. The market encompasses various types of reduction gears, including RV reducers, harmonic reducers, and others, each serving specific functions and applications. As industries worldwide increasingly adopt automation to improve productivity and reduce labor costs, the demand for precision reduction gears has surged. These gears are integral to the functioning of multi-joint robots, coordinate robots, SCARA robots, parallel robots, and other robotic systems used in manufacturing, assembly, and other industrial processes. The market is characterized by technological advancements, with manufacturers continually innovating to produce more efficient and durable gears. This growth is further fueled by the expansion of industries such as automotive, electronics, and logistics, which rely heavily on robotic automation. As a result, the Global Industry Robot Precision Reduction Gears Market is poised for significant growth, driven by the increasing need for precision and efficiency in industrial operations.

RV Reducers, Harmonic Reducers, Others in the Global Industry Robot Precision Reduction Gears Market:

RV reducers, harmonic reducers, and other types of precision reduction gears play a pivotal role in the Global Industry Robot Precision Reduction Gears Market. RV reducers, or Rotating Vector reducers, are known for their high precision and load capacity, making them ideal for applications requiring robust performance and durability. These reducers are commonly used in heavy-duty industrial robots, where they provide the necessary torque and speed reduction to ensure smooth and accurate movements. Their design allows for minimal backlash and high torsional stiffness, which are essential for maintaining precision in complex robotic tasks. On the other hand, harmonic reducers, also known as strain wave gears, offer a different set of advantages. They are renowned for their compact size, lightweight design, and high reduction ratios, making them suitable for applications where space and weight are critical considerations. Harmonic reducers are often used in smaller robots or those requiring intricate movements, such as in the electronics or medical industries. Their unique operating principle, which involves the flexing of a flexible spline, allows for high precision and repeatability, essential for tasks requiring meticulous accuracy. Besides RV and harmonic reducers, the market also includes other types of precision reduction gears, each designed to meet specific industrial needs. These may include cycloidal reducers, planetary gears, and custom-designed solutions tailored to unique applications. Cycloidal reducers, for instance, are valued for their high shock load capacity and efficiency, making them suitable for applications involving high dynamic loads. Planetary gears, with their compact design and high torque density, are often used in applications requiring high power transmission in a limited space. The diversity of precision reduction gears available in the market reflects the varied demands of different industries and applications. Manufacturers are continually innovating to develop gears that offer improved performance, efficiency, and reliability. This innovation is driven by the need to meet the evolving requirements of industries such as automotive, aerospace, electronics, and logistics, which are increasingly relying on robotic automation to enhance productivity and competitiveness. As a result, the Global Industry Robot Precision Reduction Gears Market is characterized by a dynamic landscape, with manufacturers striving to offer cutting-edge solutions that meet the diverse needs of their customers.

Multi-joint Robots, Coordinate Robots, SCARA Robots, Parallel Robots, Others in the Global Industry Robot Precision Reduction Gears Market:

The usage of Global Industry Robot Precision Reduction Gears Market spans across various types of robots, including multi-joint robots, coordinate robots, SCARA robots, parallel robots, and others. Multi-joint robots, also known as articulated robots, are widely used in manufacturing and assembly processes due to their flexibility and range of motion. Precision reduction gears are crucial for these robots as they enable precise control of each joint, ensuring accurate and smooth movements. This precision is essential for tasks such as welding, painting, and assembly, where even minor deviations can lead to defects or inefficiencies. Coordinate robots, or Cartesian robots, operate on linear axes and are often used in applications requiring high precision and repeatability, such as CNC machining and 3D printing. Precision reduction gears in these robots ensure accurate positioning and movement along each axis, contributing to the overall quality and efficiency of the process. SCARA robots, known for their speed and precision, are commonly used in pick-and-place operations, assembly, and packaging. The use of precision reduction gears in SCARA robots enhances their performance by providing the necessary torque and speed control, enabling them to handle tasks with high accuracy and speed. Parallel robots, also known as delta robots, are used in applications requiring high-speed and high-precision movements, such as in the food and pharmaceutical industries. Precision reduction gears in these robots ensure smooth and accurate movements, essential for maintaining product quality and consistency. In addition to these specific types of robots, precision reduction gears are also used in other robotic systems, including collaborative robots (cobots) and mobile robots. Cobots, designed to work alongside humans, require precision reduction gears to ensure safe and accurate interactions. Mobile robots, used in logistics and warehousing, rely on precision reduction gears for accurate navigation and movement. The versatility and importance of precision reduction gears in these various robotic applications highlight their critical role in the Global Industry Robot Precision Reduction Gears Market. As industries continue to adopt automation to improve efficiency and productivity, the demand for precision reduction gears is expected to grow, driving further innovation and development in the market.

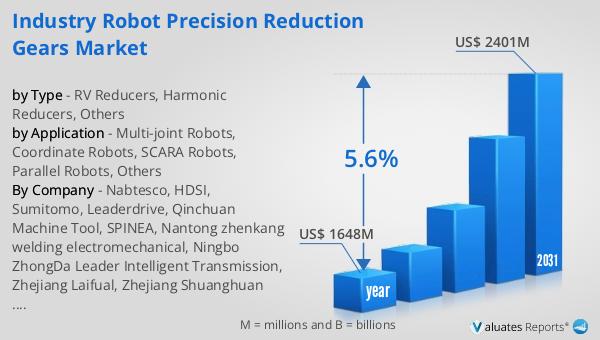

Global Industry Robot Precision Reduction Gears Market Outlook:

The outlook for the Global Industry Robot Precision Reduction Gears Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 1,648 million, and projections suggest it will expand to around US$ 2,401 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. Such expansion is indicative of the increasing reliance on industrial robots across various sectors, driven by the need for enhanced productivity and efficiency. According to the World Robotics statistical yearbook by the International Federation of Robotics (IFR), Japan stands out as the leading manufacturer of industrial robots, accounting for 45% of the global supply in 2021. This dominance underscores Japan's pivotal role in the robotics industry, particularly in the production of precision reduction gears. The country's technological advancements and manufacturing capabilities have positioned it as a key player in meeting the growing demand for high-quality robotic components. As industries worldwide continue to embrace automation, the Global Industry Robot Precision Reduction Gears Market is poised for sustained growth, supported by innovations and advancements in gear technology. This positive outlook reflects the market's potential to drive efficiency and productivity across various industrial applications.

| Report Metric | Details |

| Report Name | Industry Robot Precision Reduction Gears Market |

| Accounted market size in year | US$ 1648 million |

| Forecasted market size in 2031 | US$ 2401 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nabtesco, HDSI, Sumitomo, Leaderdrive, Qinchuan Machine Tool, SPINEA, Nantong zhenkang welding electromechanical, Ningbo ZhongDa Leader Intelligent Transmission, Zhejiang Laifual, Zhejiang Shuanghuan Driveline, Nidec-Shimpo, Shenzhen Han's Motion Technology, Wuhan Jinghua Speed Reducer Manufacturing, BENRUN Robot, KOFON, Beijing CTKM Harmonic Drive, Shanghai Like Precision Machinery, Hengfengtai Precision Machinery, Too Eph Transmission Technology, BHDI, Cone Drive, Guohua Hengyuan Tech Dev Co., Ltd., LI-MING Machinery Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |