What is Global Mobile Inspection Robot Market?

The Global Mobile Inspection Robot Market is a rapidly evolving sector that focuses on the development and deployment of robots designed to perform inspection tasks across various industries. These robots are equipped with advanced sensors, cameras, and software that allow them to navigate complex environments and gather critical data. The primary goal of these robots is to enhance safety, efficiency, and accuracy in inspection processes that are often hazardous or challenging for human workers. By automating inspections, companies can reduce the risk of accidents, lower operational costs, and improve the quality of data collected. The market is driven by technological advancements, increasing demand for automation, and the need for improved safety standards in industries such as oil and gas, energy, and manufacturing. As industries continue to embrace digital transformation, the adoption of mobile inspection robots is expected to grow, offering new opportunities for innovation and efficiency. These robots are not only transforming traditional inspection methods but also paving the way for more intelligent and connected industrial operations. The market's growth is supported by ongoing research and development efforts, as well as collaborations between technology providers and industry stakeholders.

Crawler Mobile Inspection Robot, Magnetic Wheel Mobile Inspection Robot in the Global Mobile Inspection Robot Market:

Crawler Mobile Inspection Robots and Magnetic Wheel Mobile Inspection Robots are two prominent types of robots within the Global Mobile Inspection Robot Market, each offering unique capabilities tailored to specific inspection needs. Crawler Mobile Inspection Robots are designed with tracks or treads, similar to those found on military tanks, allowing them to traverse rough and uneven terrains with ease. These robots are particularly useful in environments where traditional wheeled robots might struggle, such as construction sites, pipelines, and other industrial settings. Their robust design enables them to carry heavy payloads, including advanced sensors and cameras, making them ideal for detailed inspections in challenging conditions. Crawler robots can be remotely operated, providing real-time data and video feeds to operators, which enhances decision-making and reduces the need for human presence in potentially dangerous areas. On the other hand, Magnetic Wheel Mobile Inspection Robots are specifically engineered to adhere to and move along ferrous surfaces, such as steel structures, tanks, and pipelines. These robots use powerful magnets in their wheels to maintain contact with metal surfaces, allowing them to perform inspections in vertical or inverted positions. This capability is particularly valuable in industries like oil and gas, where infrastructure often includes large metal tanks and pipelines that require regular inspection and maintenance. Magnetic Wheel Robots are equipped with high-resolution cameras and sensors that can detect corrosion, cracks, and other structural anomalies, providing critical data to maintenance teams. Both types of robots are integral to the Global Mobile Inspection Robot Market, offering solutions that enhance safety, efficiency, and accuracy in industrial inspections. As technology continues to advance, these robots are expected to become even more sophisticated, with improved autonomy, data processing capabilities, and integration with other industrial systems. The adoption of Crawler and Magnetic Wheel Mobile Inspection Robots is driven by the need for safer and more efficient inspection methods, as well as the growing emphasis on automation and digitalization in industrial operations. By leveraging these robots, companies can optimize their inspection processes, reduce downtime, and ensure compliance with safety and regulatory standards. The versatility and adaptability of these robots make them valuable assets in a wide range of industries, from oil and gas to manufacturing and beyond. As the Global Mobile Inspection Robot Market continues to expand, the demand for innovative and reliable inspection solutions is expected to rise, driving further advancements in robot technology and applications.

Oil and Gas, Electricity and Energy, Others in the Global Mobile Inspection Robot Market:

The Global Mobile Inspection Robot Market finds extensive applications across various industries, including oil and gas, electricity and energy, and others, each benefiting from the unique capabilities of these advanced robotic systems. In the oil and gas industry, mobile inspection robots play a crucial role in ensuring the safety and integrity of infrastructure such as pipelines, storage tanks, and offshore platforms. These environments are often hazardous and difficult to access, making them ideal candidates for robotic inspection solutions. Mobile robots equipped with high-resolution cameras and sensors can navigate these challenging environments, providing real-time data on the condition of assets and identifying potential issues such as corrosion, leaks, or structural damage. By automating inspections, companies can reduce the risk of accidents, minimize downtime, and optimize maintenance schedules, ultimately improving operational efficiency and safety. In the electricity and energy sector, mobile inspection robots are used to inspect power lines, substations, wind turbines, and solar panels. These robots can operate in harsh weather conditions and difficult-to-reach locations, providing valuable data on the condition of energy infrastructure. For example, drones equipped with thermal imaging cameras can detect hotspots in power lines, indicating potential faults or failures. Similarly, robots can inspect wind turbine blades for signs of wear or damage, ensuring that maintenance is performed proactively to prevent costly breakdowns. The use of mobile inspection robots in the energy sector not only enhances safety and reliability but also supports the transition to more sustainable and efficient energy systems. Beyond oil and gas and energy, mobile inspection robots are also used in a variety of other industries, including manufacturing, transportation, and construction. In manufacturing, robots can inspect production lines and equipment for signs of wear or malfunction, helping to prevent costly downtime and maintain product quality. In transportation, robots can inspect railway tracks, bridges, and tunnels, ensuring the safety and reliability of critical infrastructure. In construction, robots can assess the condition of buildings and structures, providing valuable data for maintenance and renovation projects. The versatility and adaptability of mobile inspection robots make them valuable tools in a wide range of applications, offering significant benefits in terms of safety, efficiency, and cost-effectiveness. As industries continue to embrace automation and digitalization, the demand for mobile inspection robots is expected to grow, driving further innovation and development in this dynamic market.

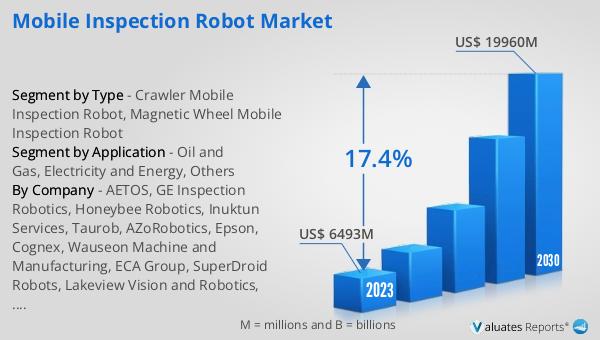

Global Mobile Inspection Robot Market Outlook:

The global market for Mobile Inspection Robots is on a significant growth trajectory, with its value estimated at $8,817 million in 2024. This market is projected to expand substantially, reaching a revised size of $26,700 million by 2031. This impressive growth is driven by a compound annual growth rate (CAGR) of 17.4% during the forecast period. This upward trend reflects the increasing demand for automation and advanced inspection solutions across various industries. As companies strive to enhance safety, efficiency, and accuracy in their operations, the adoption of mobile inspection robots is becoming more prevalent. These robots offer a range of benefits, including the ability to perform inspections in hazardous or hard-to-reach environments, reducing the need for human intervention and minimizing the risk of accidents. The market's growth is also supported by ongoing technological advancements, which are enabling the development of more sophisticated and capable robotic systems. As industries continue to embrace digital transformation and automation, the demand for mobile inspection robots is expected to rise, driving further innovation and expansion in this dynamic market. The increasing focus on safety, efficiency, and cost-effectiveness is fueling the adoption of mobile inspection robots, making them an integral part of modern industrial operations.

| Report Metric | Details |

| Report Name | Mobile Inspection Robot Market |

| Accounted market size in year | US$ 8817 million |

| Forecasted market size in 2031 | US$ 26700 million |

| CAGR | 17.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AETOS, GE Inspection Robotics, Honeybee Robotics, Inuktun Services, Taurob, AZoRobotics, Epson, Cognex, Wauseon Machine and Manufacturing, ECA Group, SuperDroid Robots, Lakeview Vision and Robotics, Genesis Systems, JH Robotics, Inspectorbots, Flyability SA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |