What is Global Corn Shelling Machine Market?

The Global Corn Shelling Machine Market is an essential segment within the agricultural machinery industry, focusing on the development and distribution of machines designed to efficiently remove corn kernels from the cob. These machines are crucial for enhancing productivity and reducing labor costs in corn processing. The market encompasses a variety of machines, each tailored to meet different scales of operation, from small-scale farms to large industrial operations. The demand for corn shelling machines is driven by the increasing global consumption of corn, which is a staple food and a key ingredient in various industrial products. Technological advancements have led to the development of more efficient and user-friendly machines, further propelling market growth. Additionally, the market is influenced by factors such as the rising need for food security, the expansion of the biofuel industry, and the growing trend of mechanization in agriculture. As a result, the Global Corn Shelling Machine Market is poised for significant growth, offering numerous opportunities for manufacturers and stakeholders to innovate and expand their product offerings.

Vertical Type Shelling Machine, Horizontal Type Shelling Machine in the Global Corn Shelling Machine Market:

In the Global Corn Shelling Machine Market, two primary types of machines are prevalent: Vertical Type Shelling Machines and Horizontal Type Shelling Machines. Vertical Type Shelling Machines are designed with a vertical orientation, where the corn is fed into the machine from the top. These machines are typically compact and are ideal for small to medium-sized operations. They are known for their efficiency in shelling corn with minimal kernel damage, making them a popular choice among farmers who prioritize quality. The vertical design allows for gravity-assisted feeding, which can enhance the speed and efficiency of the shelling process. Additionally, these machines often come with adjustable settings to accommodate different sizes and types of corn, providing versatility to the user. On the other hand, Horizontal Type Shelling Machines are characterized by their horizontal layout, where corn is fed into the machine from the side. These machines are generally larger and are suited for high-capacity operations, such as large farms or industrial processing facilities. The horizontal design allows for continuous feeding and processing, making them highly efficient for large-scale production. They are equipped with robust mechanisms to handle large volumes of corn, ensuring consistent performance even under heavy workloads. Horizontal Type Shelling Machines often feature advanced technologies, such as automated controls and sensors, to optimize the shelling process and reduce manual intervention. Both types of machines play a crucial role in the Global Corn Shelling Machine Market, catering to different needs and preferences of users. While Vertical Type Shelling Machines are favored for their compactness and precision, Horizontal Type Shelling Machines are preferred for their capacity and efficiency. The choice between the two largely depends on the scale of operation and specific requirements of the user. Manufacturers in the market are continually innovating to enhance the features and capabilities of both types of machines, aiming to improve efficiency, reduce energy consumption, and minimize kernel damage. As the demand for corn continues to rise globally, the market for both Vertical and Horizontal Type Shelling Machines is expected to grow, driven by the need for efficient and reliable corn processing solutions.

Industrial, Agriculture, Others in the Global Corn Shelling Machine Market:

The Global Corn Shelling Machine Market finds its application across various sectors, including industrial, agricultural, and others. In the industrial sector, corn shelling machines are integral to the processing of corn for various products, such as cornmeal, corn oil, and biofuels. Industrial operations require machines that can handle large volumes of corn efficiently and consistently. These machines are often equipped with advanced features, such as automated controls and high-capacity processing capabilities, to meet the demands of large-scale production. The efficiency and reliability of corn shelling machines in the industrial sector are crucial for maintaining product quality and optimizing production processes. In agriculture, corn shelling machines are vital for farmers who need to process their harvest quickly and efficiently. These machines help reduce labor costs and time spent on manual shelling, allowing farmers to focus on other essential tasks. Agricultural corn shelling machines are designed to be user-friendly and durable, capable of withstanding the rigors of farm operations. They are available in various sizes and capacities to cater to different farm sizes and production needs. The use of corn shelling machines in agriculture not only enhances productivity but also contributes to the overall mechanization of farming practices, which is essential for meeting the growing demand for food. Beyond industrial and agricultural applications, corn shelling machines are also used in other areas, such as research and development, where they play a role in studying corn varieties and improving crop yields. In educational institutions, these machines are used for training purposes, helping students understand the mechanics and importance of corn processing. Additionally, corn shelling machines are employed in community-based projects and small-scale enterprises, where they support local economies by enabling efficient corn processing. The versatility and efficiency of corn shelling machines make them indispensable tools across various sectors, contributing to the growth and sustainability of the Global Corn Shelling Machine Market.

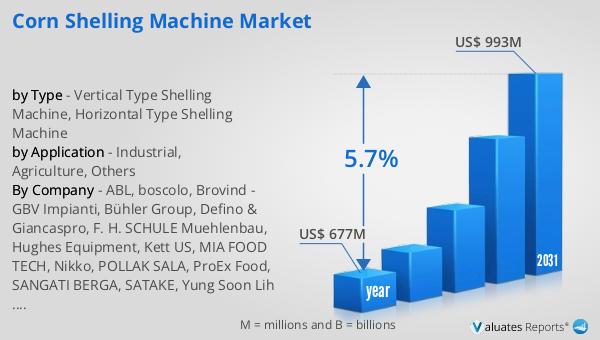

Global Corn Shelling Machine Market Outlook:

The global market for Corn Shelling Machines was valued at approximately $677 million in 2024. It is anticipated to expand significantly, reaching an estimated size of $993 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.7% over the forecast period. The increasing demand for corn, driven by its widespread use in food products, animal feed, and biofuels, is a key factor propelling the market's expansion. As the global population continues to rise, the need for efficient and reliable corn processing solutions becomes more critical, further boosting the demand for corn shelling machines. Technological advancements in machinery design and functionality are also contributing to market growth, as manufacturers strive to develop more efficient, user-friendly, and environmentally sustainable machines. The market's growth is supported by the rising trend of agricultural mechanization, which aims to enhance productivity and reduce labor costs. Additionally, the expansion of the biofuel industry, which relies heavily on corn as a feedstock, is expected to drive further demand for corn shelling machines. As a result, the Global Corn Shelling Machine Market presents significant opportunities for manufacturers and stakeholders to innovate and expand their product offerings, catering to the evolving needs of the agricultural and industrial sectors.

| Report Metric | Details |

| Report Name | Corn Shelling Machine Market |

| Accounted market size in year | US$ 677 million |

| Forecasted market size in 2031 | US$ 993 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ABL, boscolo, Brovind - GBV Impianti, Bühler Group, Defino & Giancaspro, F. H. SCHULE Muehlenbau, Hughes Equipment, Kett US, MIA FOOD TECH, Nikko, POLLAK SALA, ProEx Food, SANGATI BERGA, SATAKE, Yung Soon Lih Food Machin, TECNOCEAM, Spectrum Industries, SHAOXING WALLEY FOOD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |