What is Global Tri-Axis Vibration Shaker Market?

The Global Tri-Axis Vibration Shaker Market is a specialized segment within the broader testing and measurement equipment industry. These devices are designed to simulate the vibrations that products might encounter during their lifecycle, ensuring they can withstand real-world conditions. The "tri-axis" aspect refers to the shaker's ability to test vibrations along three different axes simultaneously, providing a comprehensive analysis of a product's durability and performance. This capability is crucial for industries where product reliability is paramount, such as automotive, aerospace, and electronics. By subjecting products to rigorous vibration testing, manufacturers can identify potential weaknesses and improve product design before mass production. This not only enhances product quality but also reduces the risk of costly recalls and failures in the field. The market for these shakers is driven by the increasing demand for high-quality, reliable products across various sectors, as well as advancements in technology that allow for more precise and efficient testing. As industries continue to innovate and develop more complex products, the need for advanced testing solutions like tri-axis vibration shakers is expected to grow, making this market an essential component of modern manufacturing and quality assurance processes.

Air Cooled, Water Cooled in the Global Tri-Axis Vibration Shaker Market:

In the Global Tri-Axis Vibration Shaker Market, cooling methods play a crucial role in the performance and efficiency of the equipment. Two primary cooling methods are employed: air-cooled and water-cooled systems. Air-cooled systems are generally more straightforward and cost-effective, making them a popular choice for many applications. They use ambient air to dissipate heat generated during the vibration testing process. This method is advantageous in environments where water resources are limited or where simplicity and ease of maintenance are prioritized. Air-cooled systems are typically easier to install and require less infrastructure, which can be beneficial for smaller operations or those with budget constraints. However, they may not be as efficient in dissipating heat as water-cooled systems, especially in high-power applications or in environments with high ambient temperatures. On the other hand, water-cooled systems offer superior cooling efficiency, making them ideal for high-power applications and environments where precise temperature control is critical. These systems use water as a cooling medium, which can absorb and dissipate heat more effectively than air. This allows for more consistent performance and can extend the lifespan of the equipment by preventing overheating. Water-cooled systems are often used in industries where high precision and reliability are required, such as aerospace and defense. However, they require a more complex infrastructure, including water supply and drainage systems, which can increase installation and maintenance costs. Additionally, water-cooled systems may pose challenges in regions where water conservation is a concern. Despite these challenges, the choice between air-cooled and water-cooled systems ultimately depends on the specific needs and constraints of the application. Factors such as the power requirements of the shaker, the ambient environmental conditions, and the availability of resources all play a role in determining the most suitable cooling method. As the Global Tri-Axis Vibration Shaker Market continues to evolve, advancements in cooling technologies are expected to further enhance the performance and efficiency of these systems, providing manufacturers with more options to meet their testing needs.

Automotive, Aerospace, Military and Defense, Consumer Electronics, Education and Research, Others in the Global Tri-Axis Vibration Shaker Market:

The Global Tri-Axis Vibration Shaker Market finds extensive applications across various industries, each with unique requirements and challenges. In the automotive sector, these shakers are used to test the durability and reliability of vehicle components, such as engines, suspensions, and electronic systems. By simulating the vibrations experienced during driving, manufacturers can identify potential issues and improve the design and performance of their products. This is crucial for ensuring vehicle safety and customer satisfaction. In the aerospace industry, tri-axis vibration shakers are employed to test the resilience of aircraft components and systems. Given the extreme conditions that aircraft are subjected to, including high speeds and altitudes, it is essential to ensure that all parts can withstand these stresses. Vibration testing helps identify weaknesses and improve the overall safety and reliability of aircraft. The military and defense sector also relies heavily on tri-axis vibration shakers to test the durability of equipment and vehicles used in harsh environments. This includes testing the resilience of weapons systems, communication devices, and transport vehicles to ensure they can perform reliably in combat situations. In the consumer electronics industry, vibration testing is used to assess the durability of products such as smartphones, tablets, and laptops. With consumers demanding more robust and reliable devices, manufacturers use tri-axis vibration shakers to simulate real-world conditions and improve product design. In the education and research sector, these shakers are used for various experimental and testing purposes, providing valuable data for developing new technologies and materials. Other industries, such as construction and energy, also utilize tri-axis vibration shakers to test the durability and performance of their products and systems. Overall, the versatility and effectiveness of tri-axis vibration shakers make them an essential tool for ensuring product quality and reliability across a wide range of applications.

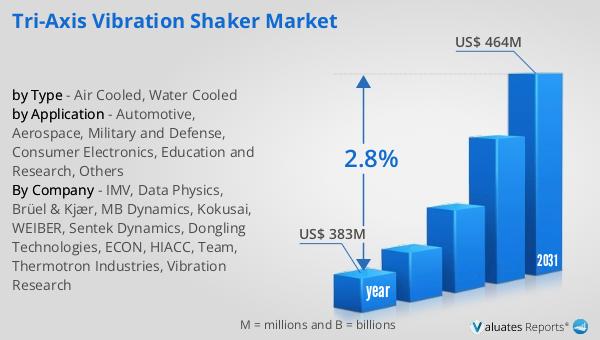

Global Tri-Axis Vibration Shaker Market Outlook:

The global market for Tri-Axis Vibration Shaker was valued at $383 million in 2024, with projections indicating it will reach a revised size of $464 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.8% over the forecast period. This steady increase in market size reflects the growing demand for reliable and efficient testing solutions across various industries. As manufacturers continue to innovate and develop more complex products, the need for advanced testing equipment like tri-axis vibration shakers becomes increasingly important. These devices play a crucial role in ensuring product quality and reliability, helping manufacturers identify potential weaknesses and improve product design before mass production. The projected growth in the market is also driven by advancements in technology, which have made these shakers more precise and efficient. As industries such as automotive, aerospace, and electronics continue to evolve, the demand for high-quality testing solutions is expected to rise, further fueling the growth of the Global Tri-Axis Vibration Shaker Market. This market outlook highlights the importance of these devices in modern manufacturing and quality assurance processes, underscoring their role in helping companies meet the increasing demands for reliable and durable products.

| Report Metric | Details |

| Report Name | Tri-Axis Vibration Shaker Market |

| Accounted market size in year | US$ 383 million |

| Forecasted market size in 2031 | US$ 464 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IMV, Data Physics, Brüel & Kjær, MB Dynamics, Kokusai, WEIBER, Sentek Dynamics, Dongling Technologies, ECON, HIACC, Team, Thermotron Industries, Vibration Research |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |