What is Global Food Pulper Market?

The Global Food Pulper Market is an essential segment of the food processing industry, focusing on machines designed to extract pulp from fruits and vegetables. These machines are crucial for producing a wide range of food products, including juices, purees, and sauces. The market is driven by the increasing demand for processed and convenience foods, which require efficient and high-quality pulping processes. Food pulpers help in reducing waste by efficiently separating the pulp from seeds, skins, and other non-edible parts, thus maximizing the yield of usable product. The market is characterized by a variety of pulpers, ranging from small-scale units for artisanal producers to large industrial machines for mass production. Technological advancements have led to the development of more efficient and versatile pulpers, capable of handling different types of produce with varying textures and consistencies. The global food pulper market is also influenced by factors such as the rising health consciousness among consumers, which drives the demand for natural and minimally processed foods. Additionally, the growing trend of sustainable and eco-friendly food production practices is encouraging manufacturers to develop energy-efficient and environmentally friendly pulping solutions. Overall, the Global Food Pulper Market plays a vital role in the food processing industry, supporting the production of a wide array of food products while promoting sustainability and efficiency.

Vertical, Horizontal in the Global Food Pulper Market:

In the Global Food Pulper Market, machines are typically categorized based on their orientation: vertical and horizontal. Vertical food pulpers are designed with a vertical configuration, where the produce is fed from the top and processed through a series of blades or screens. This design is particularly advantageous for gravity-assisted feeding, allowing for a continuous flow of produce into the machine. Vertical pulpers are often used in applications where space is limited, as their upright design requires a smaller footprint. They are also favored for their ease of maintenance and cleaning, as the vertical alignment allows for straightforward access to internal components. On the other hand, horizontal food pulpers feature a horizontal configuration, where the produce is fed from the side and processed along a horizontal axis. This design is beneficial for handling larger volumes of produce, as it allows for a more extensive processing area and can accommodate larger blades or screens. Horizontal pulpers are often used in industrial settings where high throughput is required, as they can process large quantities of produce efficiently. They are also preferred for their ability to handle a wider variety of produce types, including those with tougher skins or larger seeds. Both vertical and horizontal pulpers have their unique advantages and are chosen based on the specific needs of the food processing operation. Vertical pulpers are ideal for smaller-scale operations or those with limited space, while horizontal pulpers are better suited for large-scale industrial applications. The choice between vertical and horizontal pulpers also depends on the type of produce being processed, as certain fruits and vegetables may require specific configurations for optimal pulping. For example, softer fruits like berries may be better suited for vertical pulpers, while harder produce like apples or carrots may require the robust processing capabilities of horizontal pulpers. Additionally, the decision may be influenced by factors such as the desired consistency of the final product, the level of automation required, and the available budget for equipment investment. In summary, the Global Food Pulper Market offers a range of options for food processors, with vertical and horizontal pulpers each providing distinct benefits. The choice between these two configurations depends on various factors, including the scale of operation, type of produce, and specific processing requirements. By understanding the differences between vertical and horizontal pulpers, food processors can make informed decisions to optimize their production processes and meet the growing demand for high-quality, processed food products.

Food Processing Plant, Restaurant, Others in the Global Food Pulper Market:

The Global Food Pulper Market finds extensive usage across various sectors, including food processing plants, restaurants, and other food-related businesses. In food processing plants, food pulpers are integral to the production of a wide range of products, such as fruit juices, vegetable purees, and sauces. These machines enable processors to efficiently extract pulp from raw produce, ensuring maximum yield and minimal waste. The ability to handle large volumes of produce makes food pulpers indispensable in industrial settings, where high throughput and consistent quality are paramount. By streamlining the pulping process, food processing plants can enhance their productivity and meet the growing demand for processed foods. In restaurants, food pulpers are used to prepare fresh ingredients for various dishes, such as soups, smoothies, and desserts. The ability to quickly and efficiently process fruits and vegetables allows chefs to create high-quality, fresh-tasting dishes that appeal to health-conscious consumers. Food pulpers also help restaurants reduce food waste by maximizing the use of raw ingredients, contributing to more sustainable and cost-effective operations. Additionally, the versatility of food pulpers enables restaurants to experiment with new recipes and menu items, offering customers a diverse range of culinary experiences. Beyond food processing plants and restaurants, food pulpers are also utilized in other sectors, such as catering services, juice bars, and artisanal food producers. In catering services, food pulpers facilitate the preparation of large quantities of fresh ingredients, ensuring that events are supplied with high-quality, flavorful dishes. Juice bars rely on food pulpers to create fresh, nutrient-rich beverages that cater to the growing demand for healthy, on-the-go options. Artisanal food producers use food pulpers to craft unique, small-batch products, such as specialty jams, chutneys, and sauces, that appeal to niche markets. The adaptability of food pulpers makes them valuable tools for a wide range of food-related businesses, enabling them to meet diverse consumer preferences and market demands. Overall, the Global Food Pulper Market plays a crucial role in various sectors, supporting the production of high-quality, processed food products while promoting sustainability and efficiency. By leveraging the capabilities of food pulpers, businesses can enhance their operations, reduce waste, and deliver exceptional products to consumers.

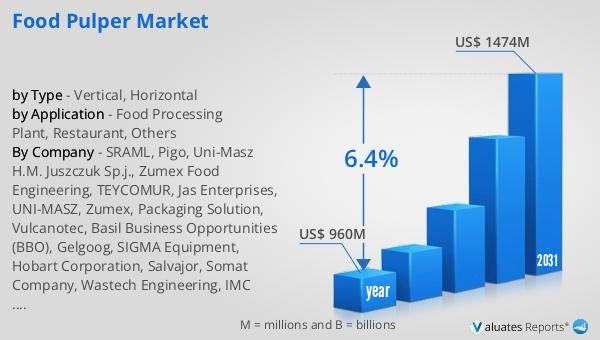

Global Food Pulper Market Outlook:

The outlook for the Global Food Pulper Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 960 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of US$ 1474 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.4% over the forecast period. This upward trend reflects the increasing demand for food pulpers across various sectors, driven by factors such as the rising popularity of processed and convenience foods, as well as the growing emphasis on sustainability and waste reduction in food production. The market's expansion is also supported by technological advancements in pulping equipment, which enhance efficiency and versatility, allowing for the processing of a wider range of produce types. As more businesses recognize the benefits of food pulpers in optimizing their operations and meeting consumer demands, the market is poised for continued growth. The projected increase in market size underscores the importance of food pulpers in the food processing industry, highlighting their role in supporting the production of high-quality, processed food products. With a focus on innovation and sustainability, the Global Food Pulper Market is set to play a vital role in shaping the future of food production.

| Report Metric | Details |

| Report Name | Food Pulper Market |

| Accounted market size in year | US$ 960 million |

| Forecasted market size in 2031 | US$ 1474 million |

| CAGR | 6.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SRAML, Pigo, Uni-Masz H.M. Juszczuk Sp.j., Zumex Food Engineering, TEYCOMUR, Jas Enterprises, UNI-MASZ, Zumex, Packaging Solution, Vulcanotec, Basil Business Opportunities (BBO), Gelgoog, SIGMA Equipment, Hobart Corporation, Salvajor, Somat Company, Wastech Engineering, IMC WasteStation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |